Blasting method capable of effectively reducing blasting boulder yield of surface mine

A large-block rate and open-pit technology, which is applied in the field of blasting to reduce the large-block rate of open-pit mining steps, can solve problems that affect mine economic benefits and production safety, increase ore mining costs, and complicated charging procedures, and achieve raw ore production costs. The effect of reducing and improving mine production efficiency and reducing the amount of secondary crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further describe the present invention, a blasting method of the present invention that can effectively reduce the large block rate of open-pit mine blasting will be further described below in conjunction with the accompanying drawings and examples.

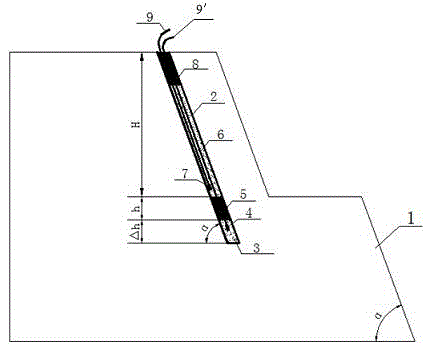

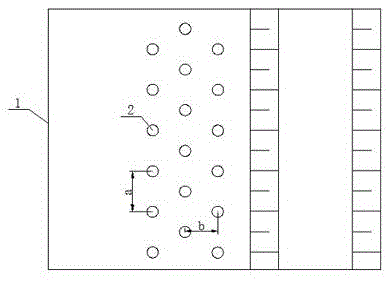

[0032] Depend on figure 1 The shown blasting network longitudinal section diagram of a blasting method design of the present invention that can effectively reduce the large block rate of open-pit mine blasting and combined figure 2 Find out that a kind of blasting method of the present invention can effectively reduce the blasting bulk rate of open-pit mine, adopt following operation:

[0033] 1) Design and construction of the blasting hole network: first, on the pre-blasting open-air step 1, according to the designed blast hole hole network parameters—blast hole distance a, blast hole row distance b, the plum blossom-shaped holes are formed to form 2 to 3 rows of blast holes 2, the distance between the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com