A method of manufacturing a waterproof LED strip

A technology of LED light strips and manufacturing methods, which is applied in the direction of air-proof/waterproof devices, components of lighting devices, semiconductor devices of light-emitting elements, etc., can solve the problems of increasing heat-melting time and increasing production costs, and achieves the reduction of limitations , Improve production efficiency, slow yellowing and deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0033] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

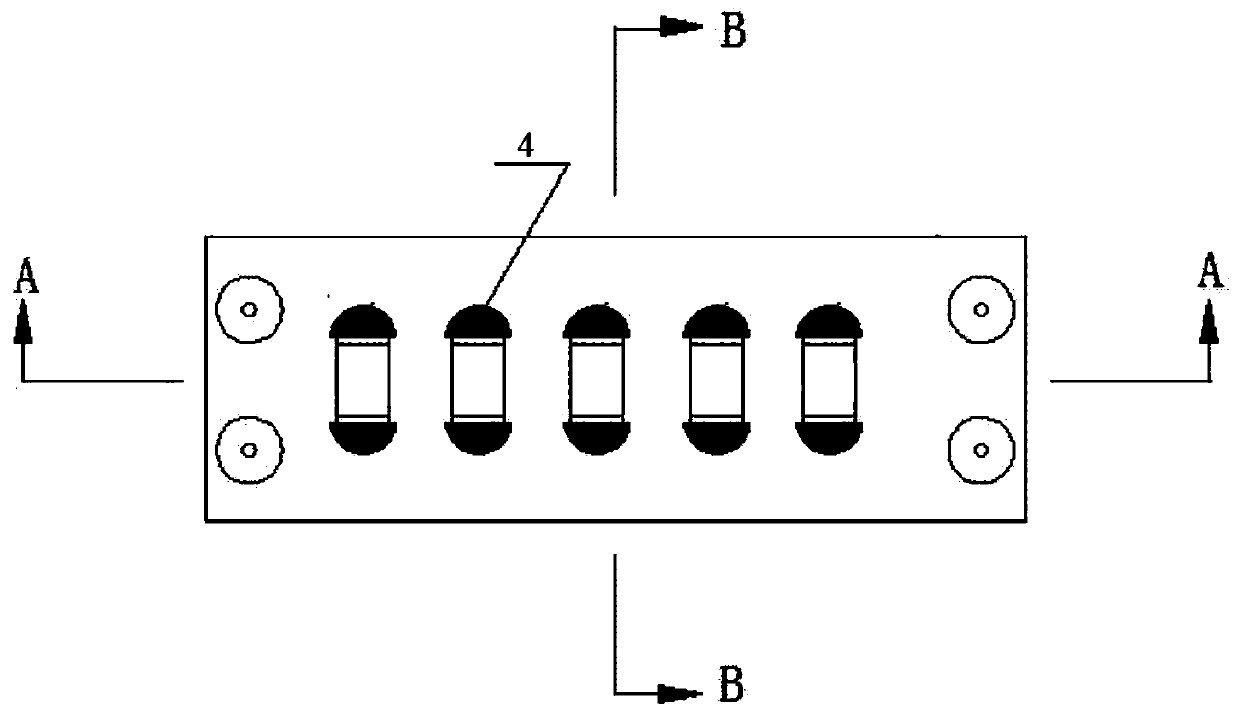

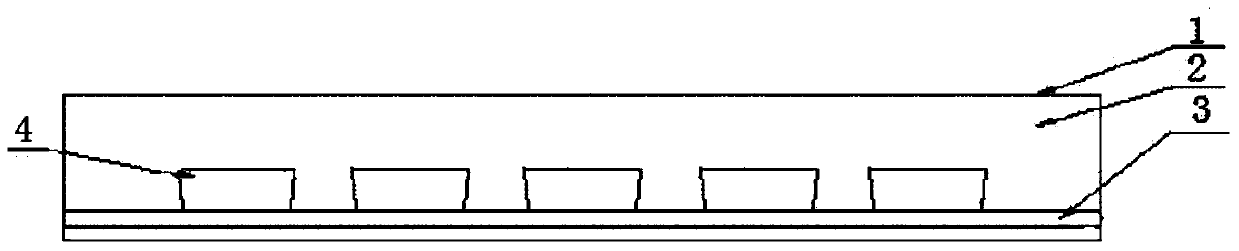

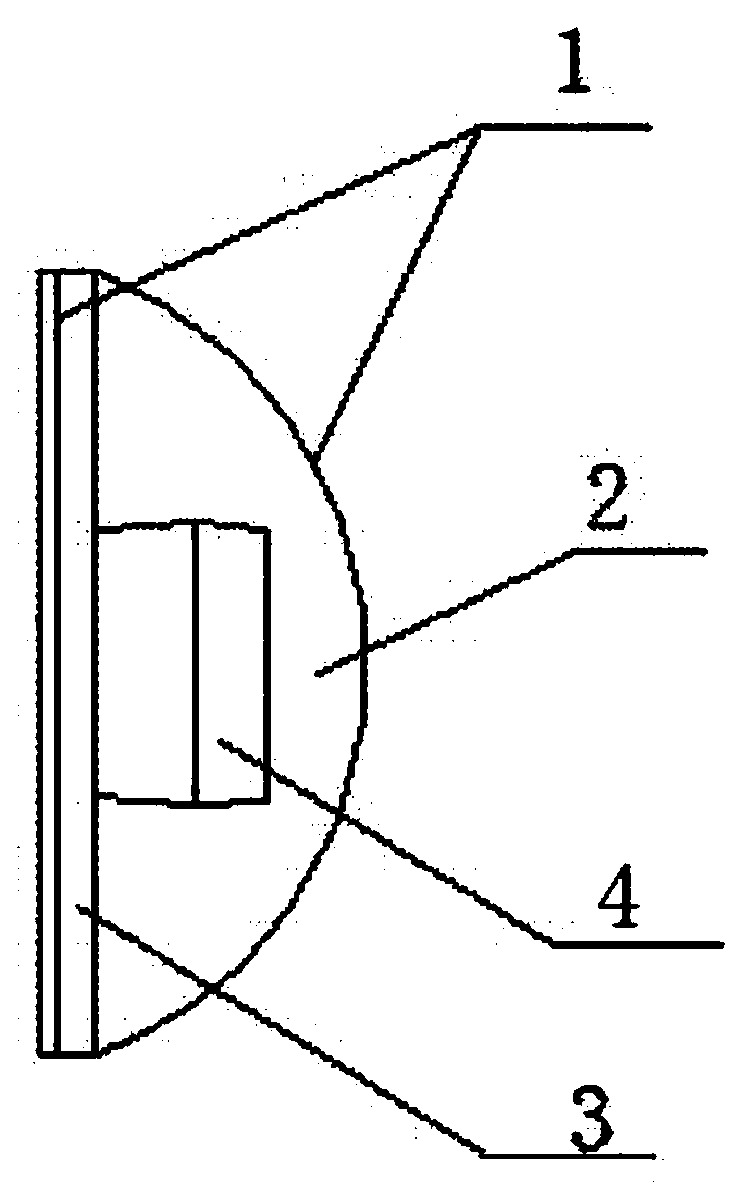

[0034] like Figure 1 to Figure 5 As shown, a method for manufacturing a waterproof LED light strip, the waterproof LED light strip includes a flexible LED circuit board 3 to be potted and a flexible transparent sleeve 1, and the manufacturing method includes the following steps:

[0035] S1: Connect the soldered and tested flexible LED circuit boards 3 to the target length; the flexible LED circuit board 3 is a copper-plated circuit board with a thickness of 0.2 mm, which can increase the flexibility and flexibility of the product. Heat dissipation; several LED lamp beads 4 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com