Sweater Dyeing Machine

A technology for dyeing machines and woolen sweaters, which is applied in the field of woolen sweater dyeing machines, can solve problems such as inability to take out from the feed port, poor performance, and knotting of woolen sweaters, so as to reduce the use and discharge of dyeing wastewater , Stable use performance, and the effect of improving use performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

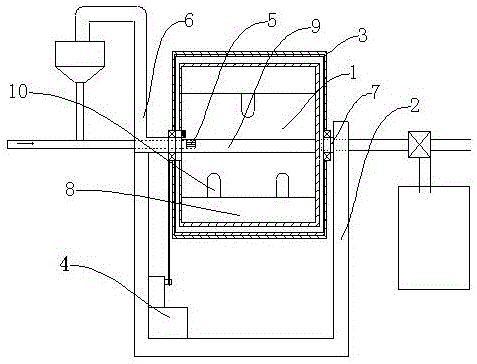

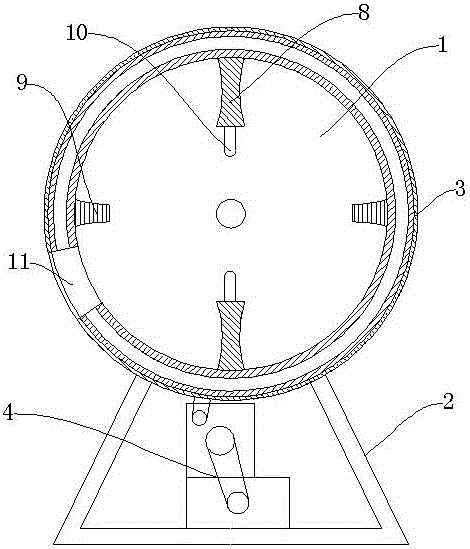

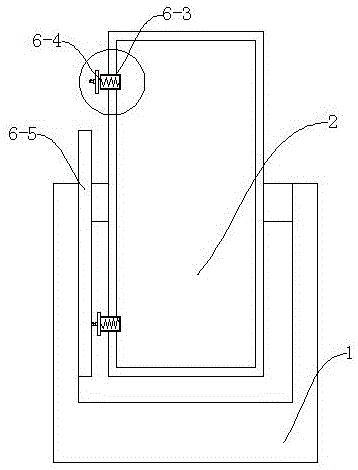

[0024] Such as figure 1 , figure 2 As shown, the woolen sweater dyeing machine described in this embodiment includes a frame 2, on which a drum 1 is arranged, and the two ends of the drum 1 are rotationally connected with the frame 2, and the drum 1 The outside of the body is covered with a layer of outer shell 3, and the drum 1 is fixedly connected with the outer shell 3, and there is a gap between the two; the frame 2 is provided with a power mechanism 4 that is connected to the drum 1 in transmission, and the machine The frame 2 is provided with a dye atomization mechanism 5, an air pressure balance mechanism 6 and a steam heating mechanism 7; the dye atomization mechanism 5 and the air pressure balance mechanism 6 are all communicated with the inside of the drum 1, and the steam heating mechanism 7 is connected with the The gap between the drum 1 and the outer casing 3 is connected; two main baffles 8 are arranged at intervals on the inner wall of the drum 1, and a secon...

Embodiment 2

[0027]The woolen sweater dyeing machine described in this embodiment includes a frame 2, on which a drum 1 is arranged, the two ends of the drum 1 are rotationally connected with the frame 2, and the drum 1 is wrapped A layer of outer shell 3 is covered, and the drum 1 is fixedly connected with the outer shell 3, and there is a gap between the two; a power mechanism 4 connected to the drum 1 is provided on the frame 2, and A dye atomization mechanism 5, an air pressure balance mechanism 6 and a steam heating mechanism 7 are provided; the dye atomization mechanism 5 and the air pressure balance mechanism 6 are all connected to the inside of the drum 1, and the steam heating mechanism 7 is connected to the drum 1 It communicates with the gap between the outer casing 3; three main baffles 8 are arranged at intervals on the inner wall of the drum 1, and a secondary baffle 9 is arranged between adjacent main baffles 8, and the main baffle 8 and The axial length of the auxiliary baf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com