Automatic bag opening and discharging device

A bag-out, automatic technology, applied in the field of automatic bag-unpacking and discharging device, can solve the problems of unfavorable conveying of empty bags by a large screw shaft, poor collection effect of granular materials, etc., and achieve the effects of low cost, simple structure and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

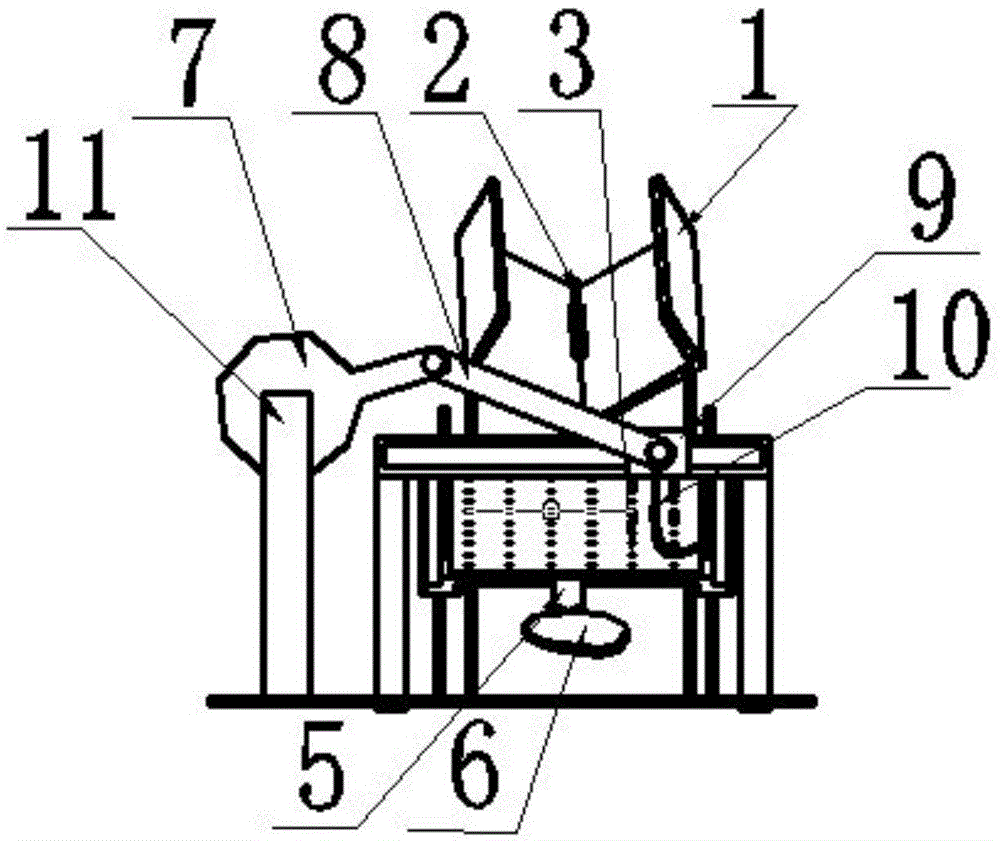

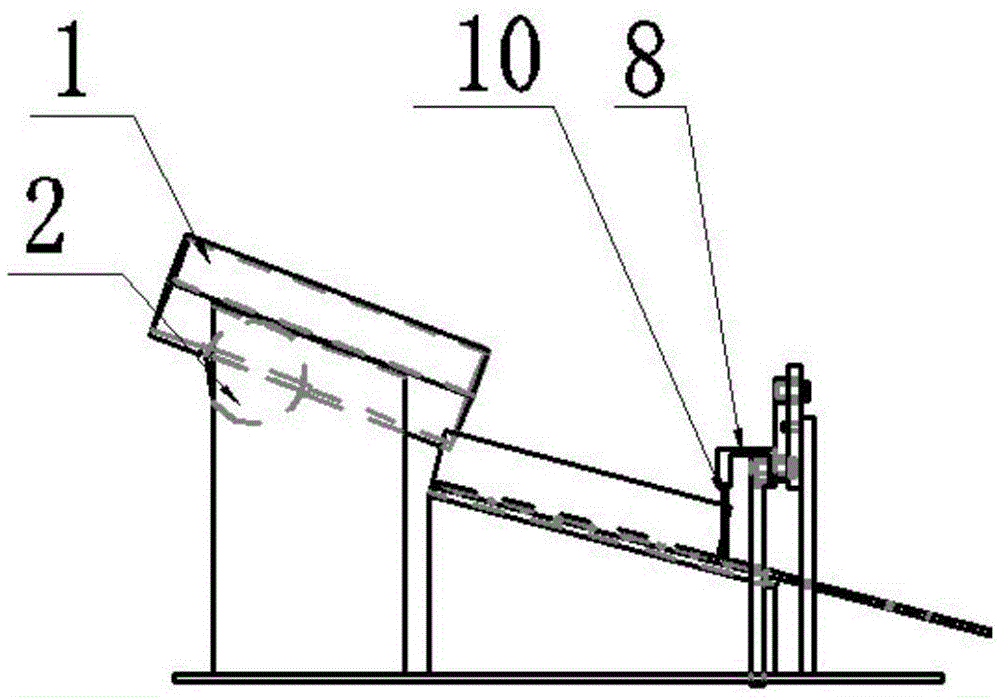

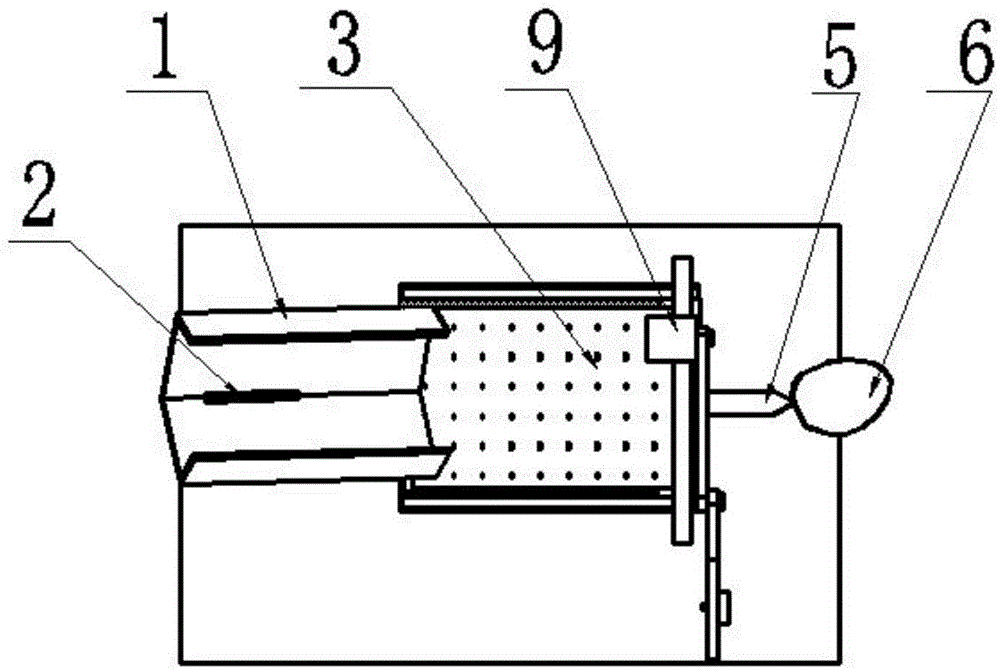

[0034] Please check Figure 1 to Figure 10 , an automatic bag unpacking and discharging device, including a trough 1, a saw blade 2 installed in the trough 1 to cut through material bags, a screen support 4, a screen 3 that can slide back and forth relative to the screen support 4, and a first drive Mechanism, connecting rod bracket 11, the slide block 9 that is slidably connected on the connecting rod bracket 11, the hook 10 that is fixedly installed on the slide block 9 and the second driving mechanism. This material bag refers to, and it comprises the bag that opening is closed and the material that is installed in the bag, and this material is as coal ash, cement etc., and coal ash is taken as example below.

[0035] The chute 1 has an upper port and a lower port, and the upper port and the lower port are inclined from top to bottom, and the inclination angle of the chute is, for example, 30-60 degrees. In this embodiment, the section of the trough 1 includes a V-shaped s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com