Roller blind lifting device for vehicle and using method thereof

A lifting device and roller shutter technology, applied in vehicle parts, transportation and packaging, windows, etc., can solve the problem that the rack movement space is easy to interfere with the vehicle body, and achieve the effect of avoiding interference movement, compact structure, and shortened size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

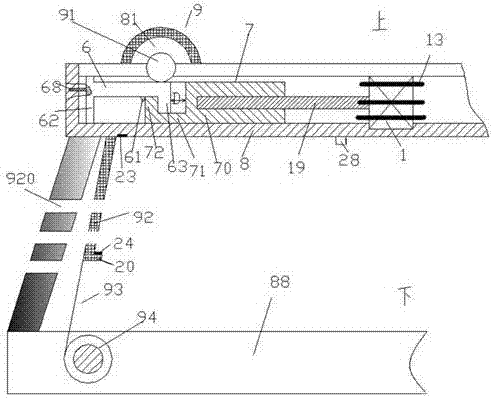

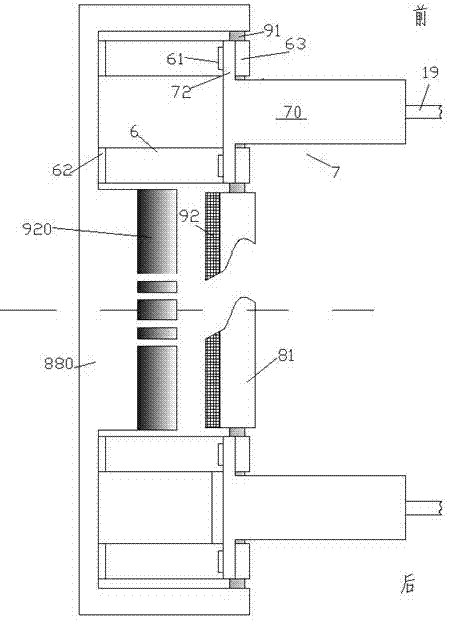

[0012] Combine below Figure 1-2 The present invention will be described in detail.

[0013] A roller blind lifting device for a vehicle according to an embodiment includes a fixed frame part 8 fixed on a vehicle body 88, and a roller blind assembly 9 pivotable relative to the fixed frame part 8, and the roller blind assembly 9 It includes a roller blind reel 81 that is fixedly connected to the upper end of the roller blind 92 and can wind the roller blind 92, a driving shaft gear 91 that is symmetrically coaxially arranged at the front and rear sides of the roller blind reel 81, and through The biasing pivoting wheel 94 that flexible pulling cable is fixedly connected with the lower end of described roller blind, described biasing pivoting wheel 94 is biased by pivoting biasing spring so that described roller blind 92 is pulled toward downward; Two rack drive assemblies symmetrically positioned on the front and rear sides of the roller blind reel 81 are arranged in the fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com