Automatic universal mold clamping mechanism for die casing machine or injection molding machine

A mold clamping mechanism and injection molding machine technology, applied in the field of die casting or injection molding equipment design and manufacture, can solve the problem of not being able to adjust at any time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

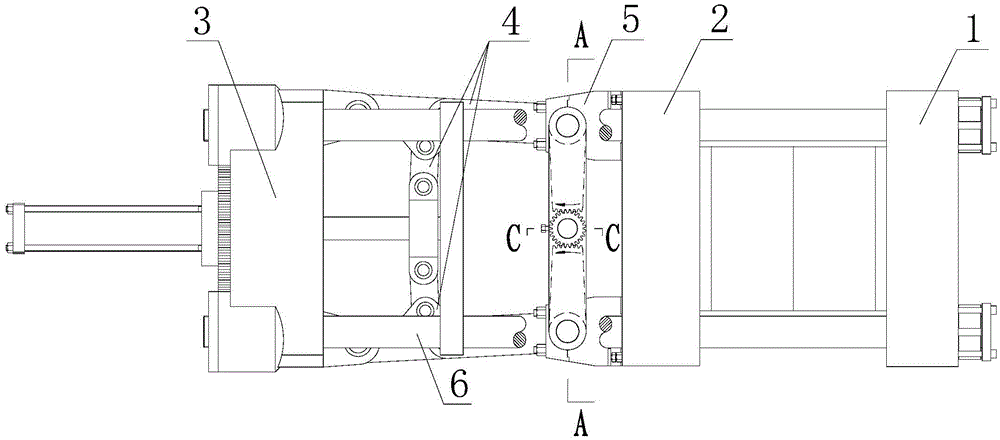

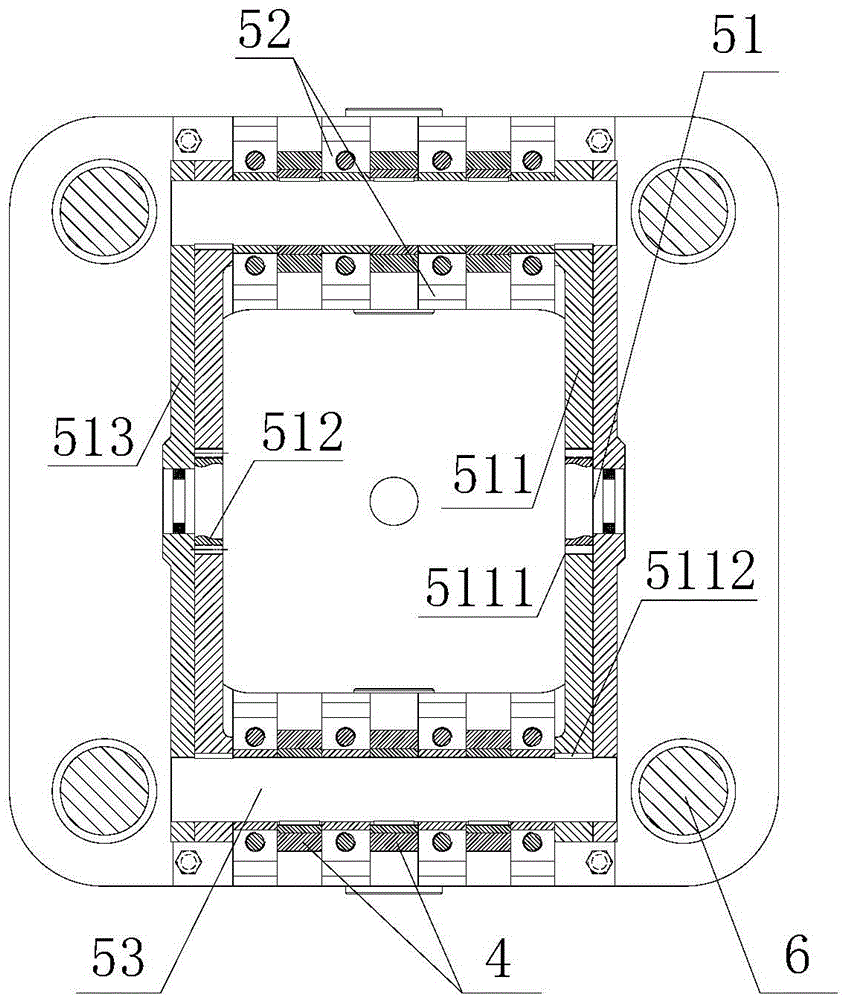

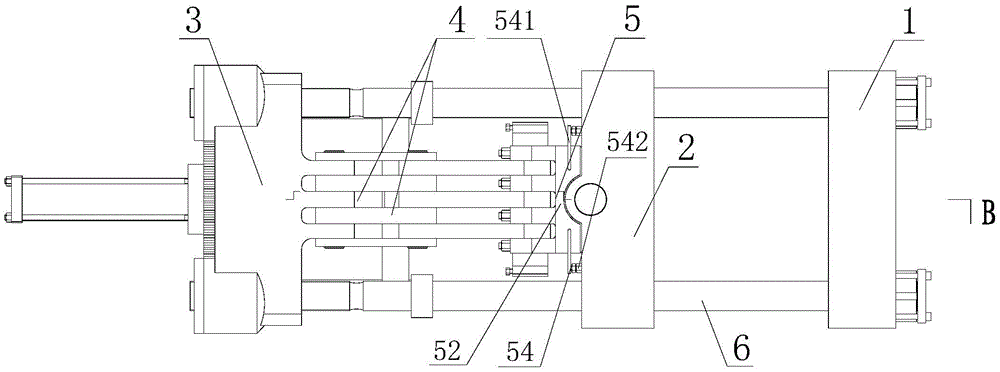

[0030] Such as Figure 1 to Figure 11 Shown is an automatic universal mold clamping mechanism for a die-casting machine or an injection molding machine provided by the present invention, which can effectively avoid inconsistent gaps between the movable mold plate and the static mold plate after mold clamping during the operation of the mold plate. The automatic universal mold clamping mechanism includes a static template 1, a movable template 2, a tail plate 3, a machine hinge 4 and a machine-hinge compound connection structure 5, and one end of the machine-hinge compound connection structure 5 passes through the machine hinge 4 Connected to the tail plate 3, the other end of the machine-hinged composite connection structure 5 is hinged to the movable template 2, and under the action of the driving force of the hinge, the movable template 2 is compositely connected through the hinge The cooperation between the structure 5 and the hinge 4 can move back and forth with respect to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com