Automatic cylinder bearing dismounting equipment

A bearing and equipment technology, applied in the field of automatic cylinder bearing disassembly equipment, can solve the problems of difficult removal process, bearing surface damage, bearing skew, etc., to achieve the effect of strong practical performance and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

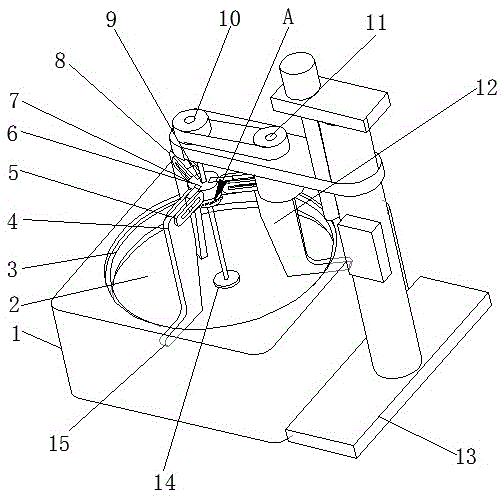

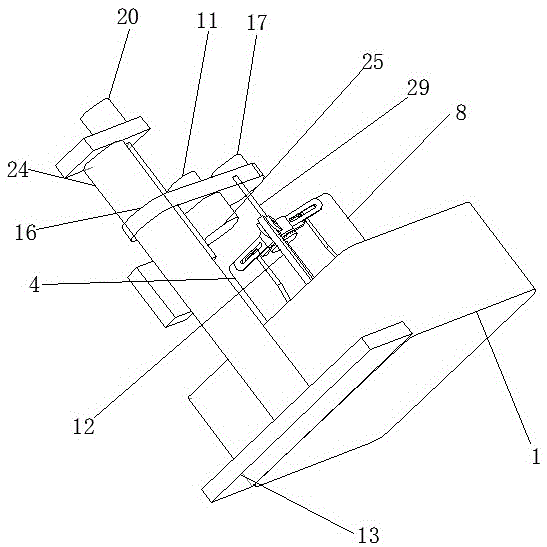

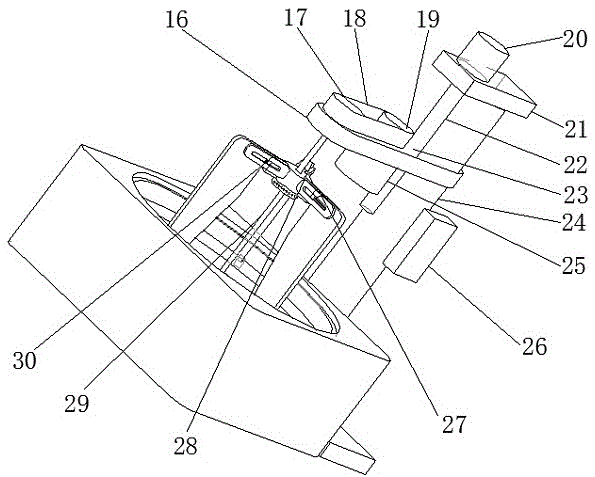

[0016] Below in conjunction with accompanying drawing, the present invention is described in detail below.

[0017] As shown in the accompanying drawings, an automatic cylinder bearing removal equipment includes a three-claw adjustable clamping mechanism, a bearing lifting mechanism for lifting the three-claw adjustable clamping mechanism, and a fast lifting platform. That is, the three-jaw adjustable clamping mechanism mainly includes a lifting platform 7, the lifting platform is cylindrical, and is divided into upper and lower parts, and the upper part of the lifting platform is processed with three slideways 6, so The included angle between the centerlines of the slideways is 120 degrees. The first fastening lug 27, the second fastening lug 28 and the third fastening lug 30 are installed in the said slideway, and the said fastening lug can be along the The slideway slides, and one end of the fastening ear is processed with a thread hole, and the first leg 4, the second leg ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com