Suction gun

A technology of tin suction gun and shell, applied in the field of tin suction gun, can solve the problems of laborious disassembly, difficult to remove and replace the tin storage cylinder, etc., and achieve the effect of accurate tin suction operation, high reliability and good hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

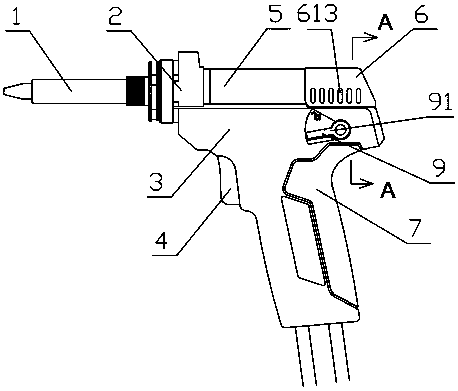

[0025] A tin suction gun, comprising a gun head 1, a gun head seat 2, a casing 3, a trigger 4, a tin storage cylinder 5, a back seat 6, and an anti-slip sleeve 7. Anti-slip cover 7 is arranged on the handle.

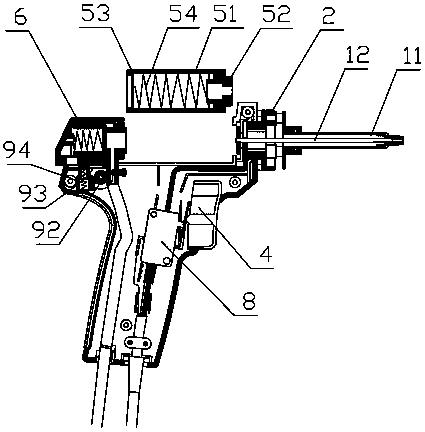

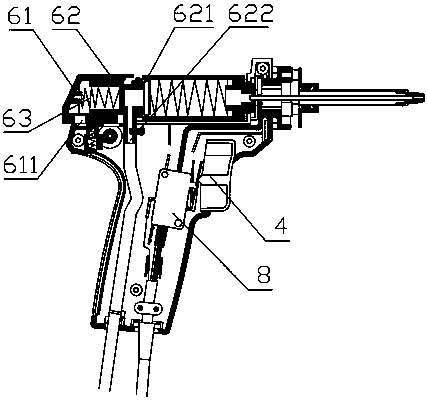

[0026] The gun head 1 is installed on the gun head seat 2 through bolts, and the gun head seat 2 is embedded in the shell 3 . The gun head includes a heating body 11 and a tin suction tube 12, the tin suction tube is connected to the air hole at one end of the tin storage cylinder, and the other end of the tin storage cylinder is connected to a negative pressure generator.

[0027] The tube body 51 of the tin storage tube is a glass tube, which is convenient for observing the amount of tin slag inside. Its one end is provided with the front seat 52 that cooperates with gun head seat, and the front seat is provided with spring seat, and the other end is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com