Pipeline inner-wall cleaning device

A technology for cleaning devices and pipelines, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of high cost, no good, difficult to take out, etc., and achieve broad market prospects, simple structure, and easy operation and maintenance convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Typical implementations of the present invention will be described below in conjunction with specific drawings.

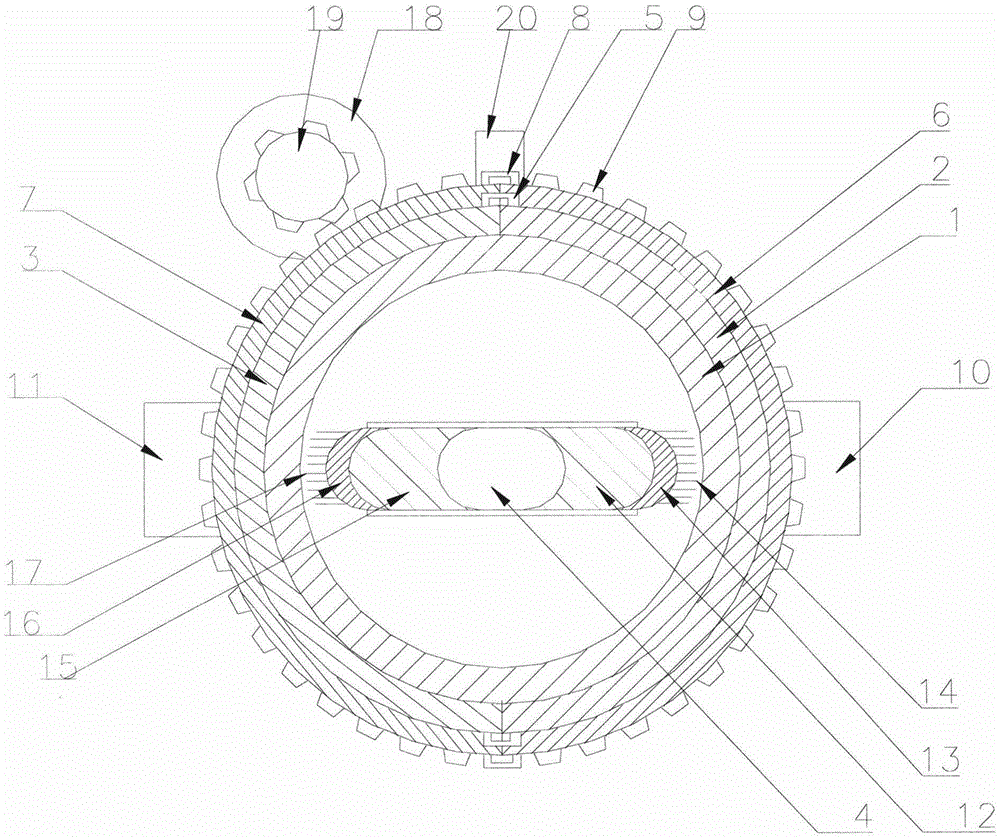

[0019] Such as Figure 1-2 Shown:

[0020] The present invention is achieved in the following ways:

[0021] Pipeline inner wall cleaning device mainly consists of right inner lining ring (2), left inner lining ring (3), inner wall cleaning rotor (4), inner lining ring snap ring (5), right outer swivel ring (6), left outer swivel Ring (7), outer swivel snap ring (8), motor (18), gear (19), half ring cover (21) forms.

[0022] The right inner lining ring (2) and the left inner lining ring (3) are connected by two inner lining ring snap rings (5) to form a complete ring, which is hooped on the pipe (1); the right outer swivel ring (6) and the left outer The swivel (7) is connected by two outer swivel snap rings (8) to form a complete ring, which is hooped on the inner lining ring; the right magnet (10) is fixed on the right outer swivel (6), and the left ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com