Metal contaminating and water thermal aging method for catalytic cracking catalyst

A catalytic cracking and hydrothermal aging technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of economy, convenience, poor environmental protection, cumbersome operation steps, slow drying process, etc. problems, to achieve strong convenience and flexibility, simple equipment structure, and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This example is used to illustrate the metal contamination and hydrothermal aging method of the catalytic cracking catalyst provided by the present invention.

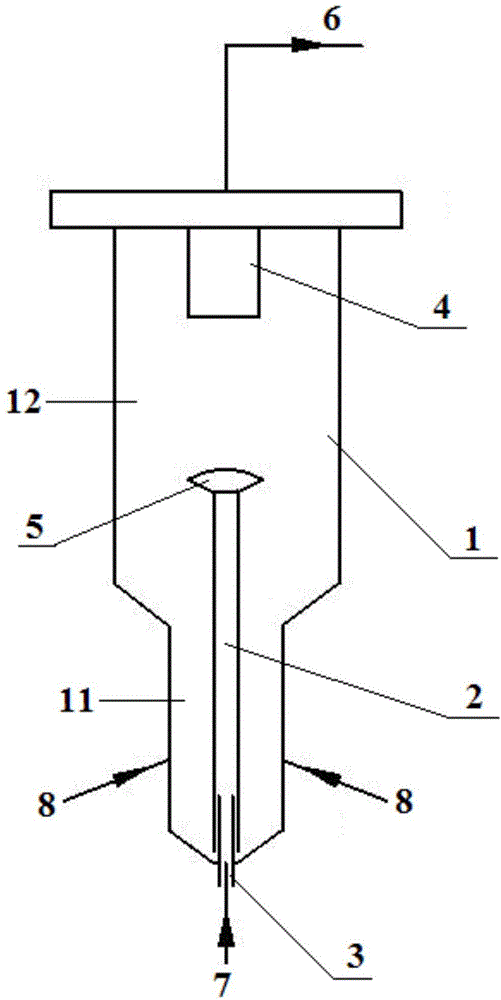

[0053] use figure 1 The shown equipment carries out metal pollution and hydrothermal aging on the catalytic cracking catalyst. Specifically, the catalytic cracking catalyst to be treated is fed into the aging device 1 from the top, and the fluidizing air is injected from both sides of the settling area 11 at the lower part of the aging device 1. After the temperature of device 1 was raised to 500°C, the fluidizing air was replaced with a fluidizing medium containing 50% by volume of water vapor, wherein, the superficial linear velocity of aging device 1 was 0.05m / s, and the average temperature was 750°C; the air was passed through The pipeline 3 leads into the riser 2, and the hydrocarbon oil containing metal-organic compounds is also passed into the riser 2 through the pipeline 3, and the hydrocarbon oil is bur...

Embodiment 2

[0055] This example is used to illustrate the metal contamination and hydrothermal aging method of the catalytic cracking catalyst provided by the present invention.

[0056] use figure 1 The shown equipment carries out metal pollution and hydrothermal aging on the catalytic cracking catalyst. Specifically, the catalytic cracking catalyst to be treated is fed into the aging device 1 from the top, and the fluidizing air is injected from both sides of the settling area 11 at the lower part of the aging device 1. After the temperature of device 1 is raised to 500°C, replace the fluidizing air with a fluidizing medium containing 50% by volume of water vapor, wherein the superficial linear velocity of aging device 1 is 3m / s, and the average temperature is 550°C; the air passes through the pipeline 3 into the riser 2, and the hydrocarbon oil containing metal-organic compounds is also passed into the riser 2 through the pipeline 3, and the hydrocarbon oil is burned in the riser 2, wh...

Embodiment 3

[0058] This example is used to illustrate the metal contamination and hydrothermal aging method of the catalytic cracking catalyst provided by the present invention.

[0059] use figure 1 The shown equipment carries out metal pollution and hydrothermal aging on the catalytic cracking catalyst. Specifically, the catalytic cracking catalyst to be treated is fed into the aging device 1 from the top, and the fluidizing air is injected from both sides of the settling area 11 at the lower part of the aging device 1. After the temperature of device 1 is raised to 500°C, replace the fluidizing air with a fluidizing medium containing 50% by volume of water vapor, wherein the superficial linear velocity of aging device 1 is 1m / s, and the average temperature is 650°C; the air passes through the pipeline 3 into the riser 2, and the hydrocarbon oil containing metal-organic compounds is also passed into the riser 2 through the pipeline 3, and the hydrocarbon oil is burned in the riser 2, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com