Sulfur-copper-tin-zinc hollow-structure microsphere and preparation method and application thereof

A technology of sulfur copper tin zinc and hollow structure is applied in the field of materials, which can solve the problems of excessively wide band gap and low efficiency, and achieve the effect of large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the sulfur-copper-tin-zinc hollow structure microspheres of the present invention comprises the following steps:

[0024] A, raw material cupric chloride, stannous chloride and thiourea 1:1:3 molar ratio are dissolved in ethylene glycol and form sample solution;

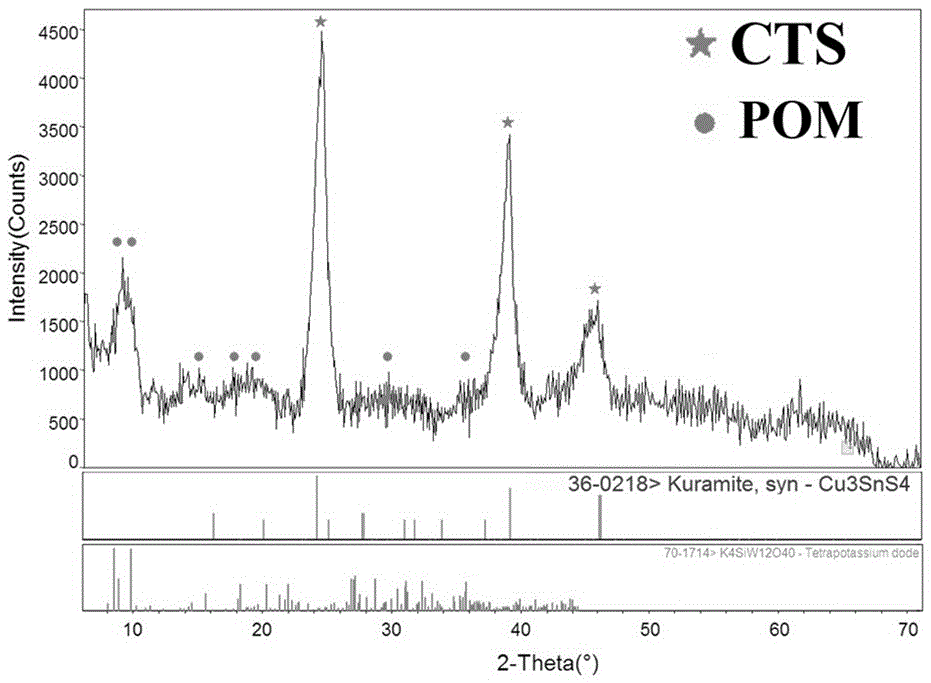

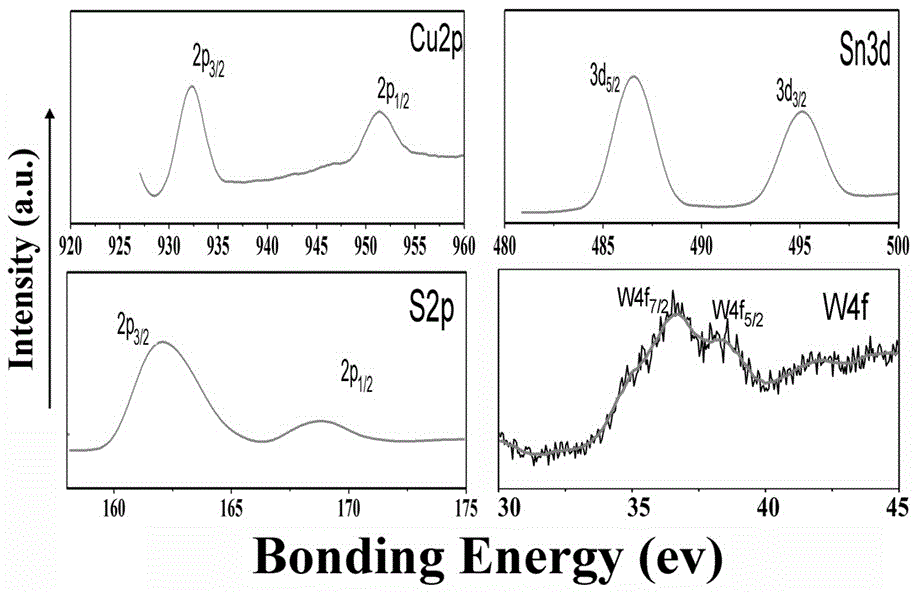

[0025] B. Add K to the sample solution 4 SiW 12 o 40 The template agent is heat-treated to obtain the target sulfur-copper-tin-zinc hollow structure microspheres.

[0026] In step B, the heat treatment temperature is 180-200° C., and the treatment time is 22-26 hours.

[0027] Step B is to transfer the sample solution to a polytetrafluoro container and fix it in a stainless steel reaction kettle, and place the stainless steel reaction kettle in an oven for heating.

[0028] The step B also includes cooling and removing impurities from the sulfur-copper-tin-zinc hollow structure microspheres.

[0029] The impurity removal is to centrifuge the sulfur-copper-tin-zinc hollow structur...

Embodiment 1

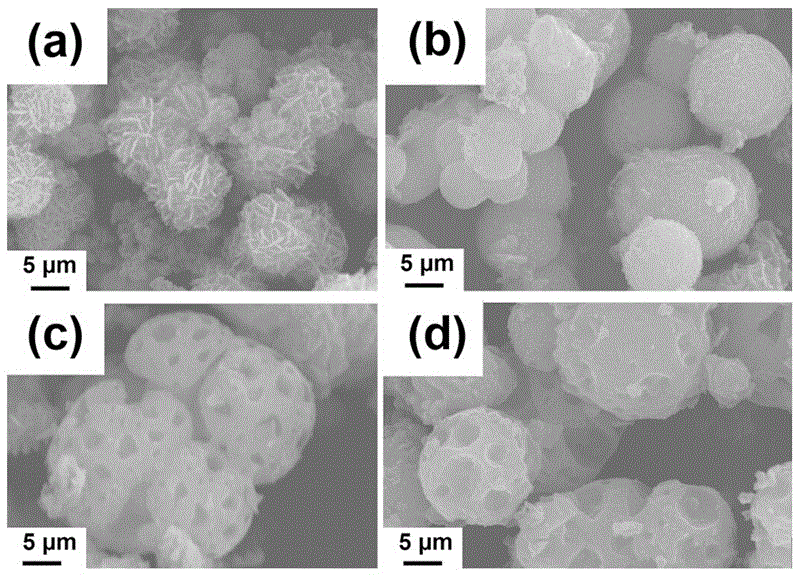

[0036] 2mM SnCl 2 .2H 2 O, 2mM CuCl 2 .2H 2 O, 6mM thiourea and 10 -3 mmolK 4 SiW 12 o 40 Add it to a 50ml DMF beaker to dissolve, transfer it to a 100ml Teflon-lined stainless steel autoclave, and keep it heated in a hot air oven at 200°C for 24h. The precipitate is centrifuged at 6000rpm for 10min from the solution, and used to Ionized water and ethanol with a concentration of 10% by volume were alternately washed 3 times, and then dried at a vacuum degree of 0.1 MPa and a temperature of 70°C for 6 hours to obtain the target product.

Embodiment 2

[0038] 2mM SnCl 2 .2H 2 O, 2mM CuCl 2 .2H 2 O, 2mM thiourea and 10 -5 mmolK 4 SiW 12 o 40 Add it to a 50ml DMF beaker to dissolve, transfer it to a 100ml Teflon-lined stainless steel autoclave, and keep it heated in a hot air oven at 200°C for 24h. The precipitate is centrifuged at 6000rpm for 10min from the solution, and used to Ionized water and ethanol with a concentration of 10% by volume were alternately washed 3 times, and then dried at a vacuum degree of 0.1 MPa and a temperature of 70°C for 6 hours to obtain the target product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com