Pneumatic tire, and method of manufacturing same

A technology of pneumatic tires and tires, which is applied in the direction of pneumatic tires, tire measurement, tire parts, etc. It can solve the problems of tire unevenness, tire physical deterioration, and difficulty in maintaining fastening force for a long time, and achieve firm fixation and excellent durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3、 comparative example 1-2

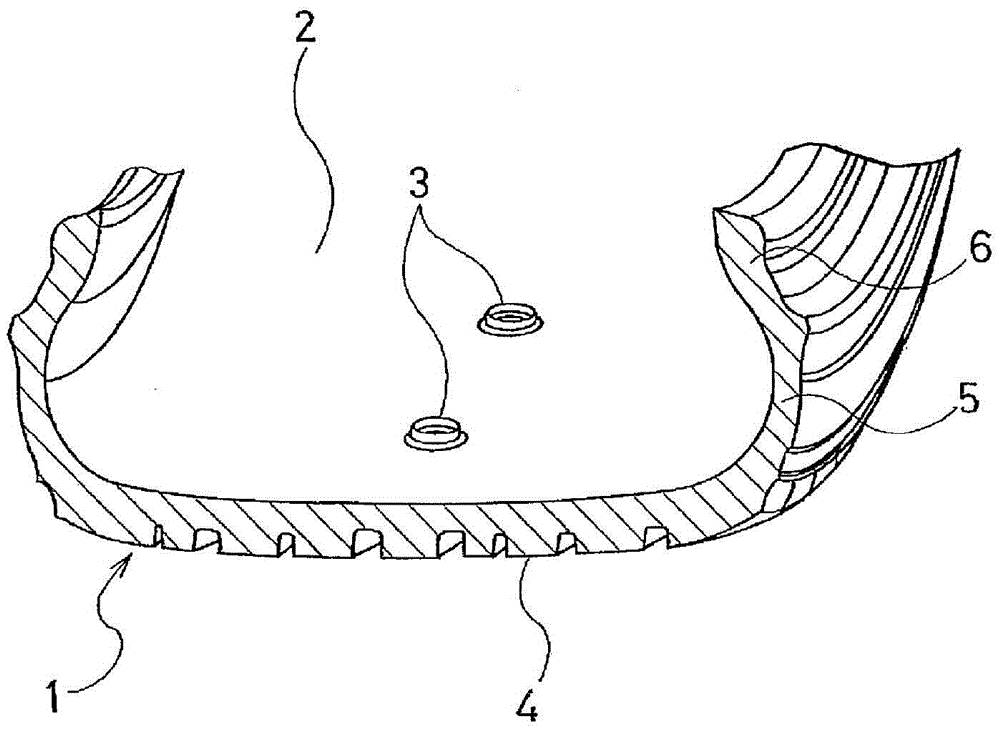

[0108] As a mechanical fastener member, the use of Figure 8 a or Figure 8 The mechanical fastener member of the form shown in b, for Figure 15 On the equatorial part of the inner peripheral surface of the tread portion of the pneumatic tire for construction vehicles shown in the model diagram of , one mechanical fastener member 3 is vulcanized and bonded in the vulcanization molding process of the tire.

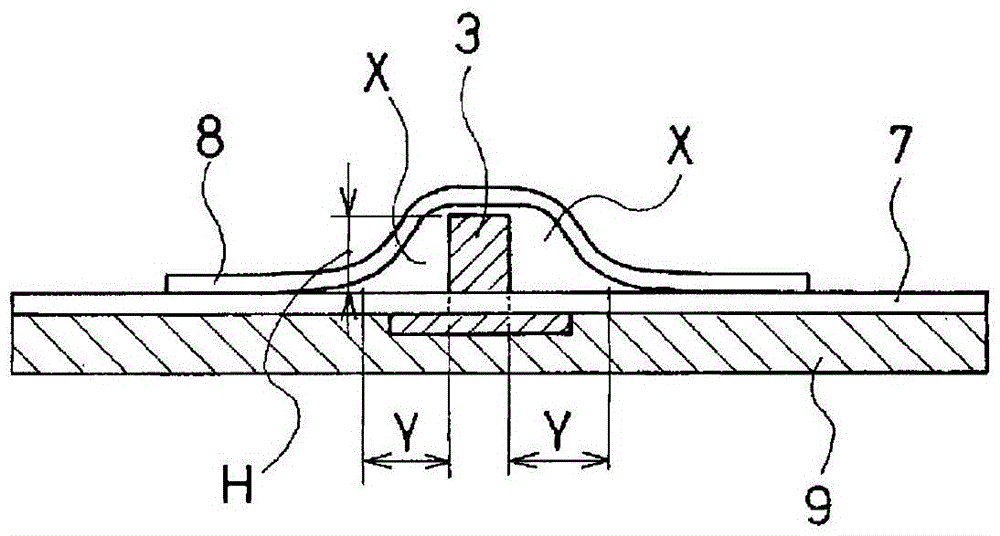

[0109] Embodiment 1~3, all adopt Figure 9 The ferrule member of the form shown in (a) is made from fluororesin "Teflon" (registered trademark). In Comparative Examples 1 and 2, none of the ferrule members was used, and the others were the same as in the Examples, and they were vulcanized and bonded during the vulcanization molding process of the tire.

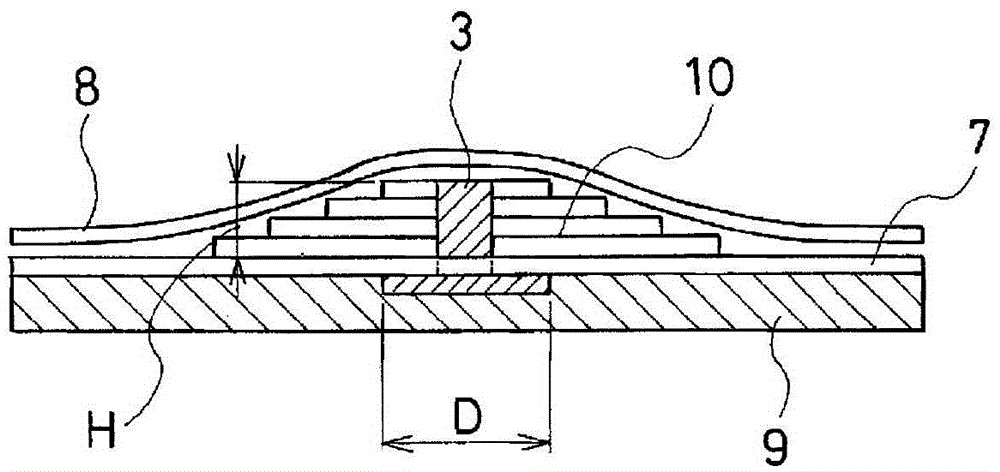

[0110] Table 1 shows the protrusion height H (mm) and the largest part diameter D (mm) of the mechanical fastener members of each test tire protruding from the inner surface of the tire.

[0111] Table 1 shows the resu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com