Cylindrical vibration-isolation device

A vibration-isolated, cylindrical technology, applied in non-rotational vibration suppression, springs made of plastic materials, springs/shock absorbers, etc., can solve the problem of poor installation spring characteristics, main body rubber elastomer durability, difficult to avoid outer cylinder members Large diameter, rubber stopper, etc., achieve the effect of easy demoulding work, excellent manufacturing easiness, and prevention of lowering of mounting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

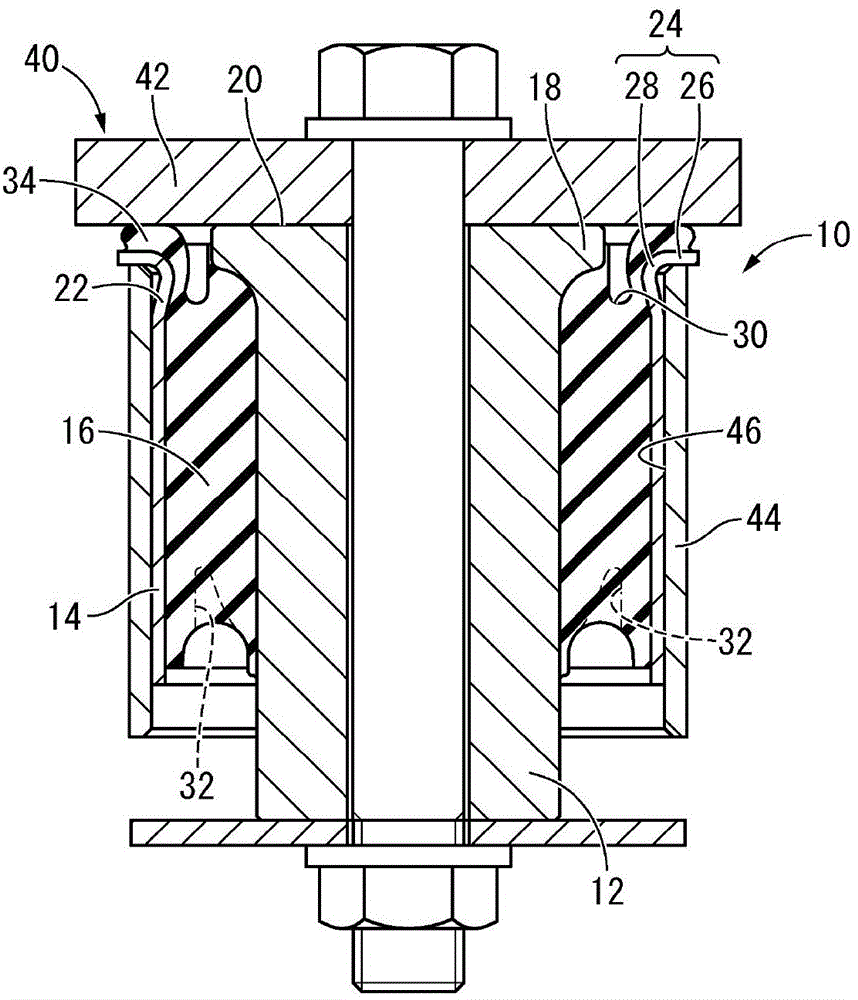

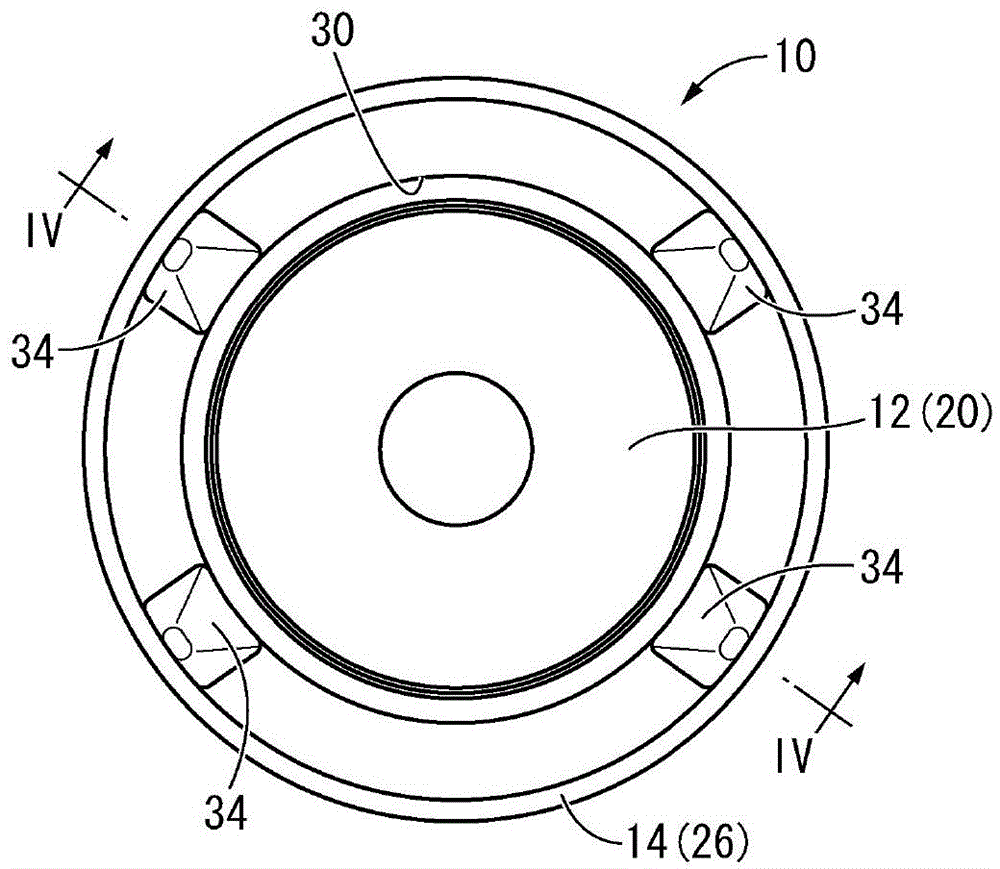

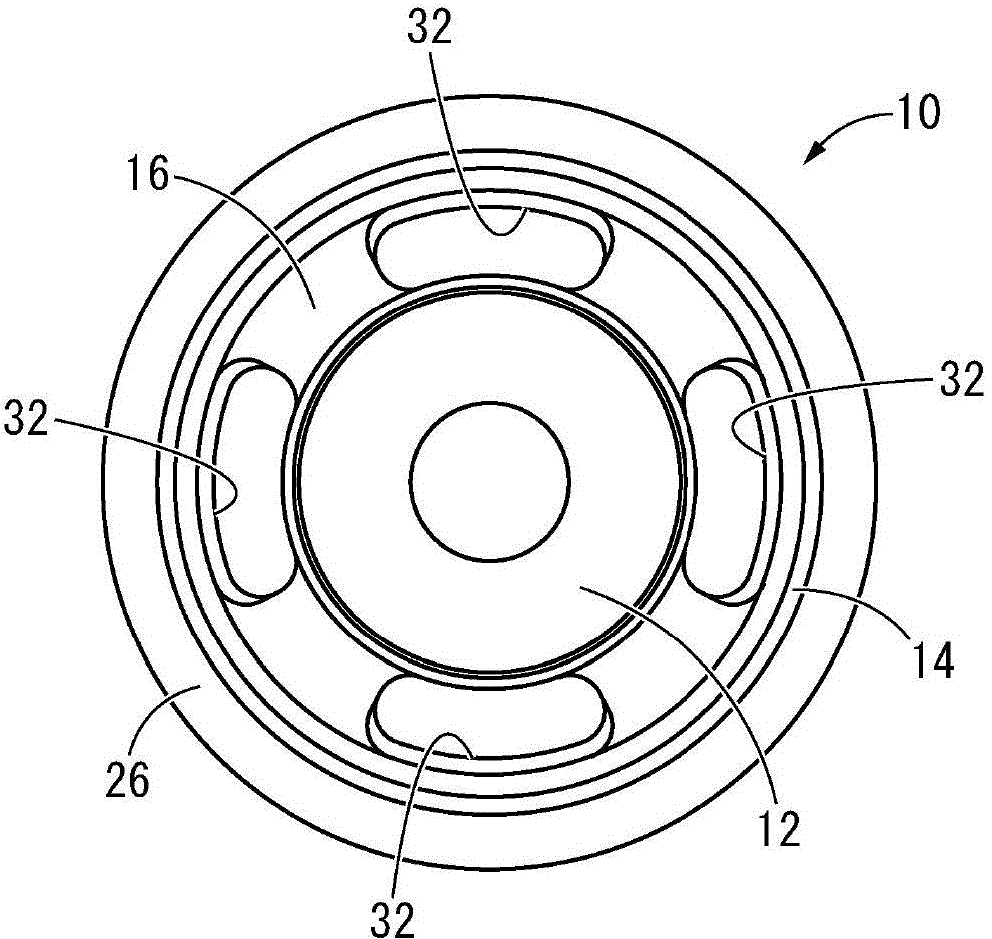

[0036] exist figure 1 In the figure, the suspension member mounting seat 10 is shown as the first embodiment of the cylindrical vibration isolating device having the structure based on the present invention. The suspension member mount 10 has a structure in which an inner shaft member 12 and an outer cylinder member 14 are arranged to fit inside and outside at a predetermined interval, and the inner shaft member 12 and the outer cylinder member 14 are elastically connected by a main rubber elastic body 16 . In addition, in the following description, the up-down direction means in principle figure 1 in the up and down direction.

[0037] In more detail, the inner shaft member 12 is a highly rigid member formed of iron, aluminum alloy, etc., such as Figure 2 ~ Figure 4 As shown, it has a roughly cylindrical shape with a thick wall and a small diameter. In addition, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com