Method for building municipal pipeline hydraulic model

A hydraulic model and construction method technology, applied in the field of municipal engineering information, can solve problems such as long calculation time and result error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

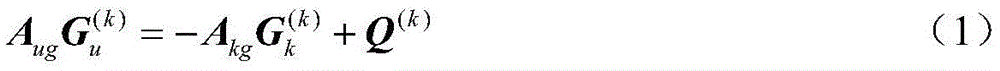

[0043] Specific implementation mode one: combine figure 1 To describe this embodiment,

[0044] A method for constructing a hydraulic model of a municipal pipe network, comprising the following steps:

[0045] Step 1. Obtain the pipe network topology, node pipe section elevation, water pump performance curve and valve opening information of the pipe network system by obtaining design materials such as pipe network system design and construction drawings, and establish a pipe network static database;

[0046] The topology structure includes node and pipe section information; involving nodes, pipe sections and resistance numbers: a node refers to a connecting node at a branch of a pipe network, and the flow rate of the pipe section connected to a node is different; a pipe section generally refers to a pipeline, and for two pipelines connected There is actually a branch at the branch but there is no flow at the branch, that is to say, two connected pipes with the same flow rate ...

specific Embodiment approach 2

[0071] The specific process of collecting node pressure and pipe flow observation data under multiple working conditions described in step 3 of this embodiment is as follows:

[0072] Obtain pressure and flow observation data by using the pressure and flow test devices set up at nodes and pipe sections in the pipe network under fire, night and normal hydraulic conditions.

[0073] Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0074] In this embodiment, the pressure and flow observation data obtained by using the pressure and flow test devices installed at the nodes and pipe sections of the pipe network under fire protection, night and normal hydraulic working conditions are 2:00-3:00 at night, that is, the nighttime hydraulic pressure The working condition is the hydraulic working condition between 2:00-3:00.

[0075] Other steps and parameters are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com