Unidirectional magnetization semiconductor waveguide integration multiple-mode interference magneto-optical isolator

A waveguide integration and multi-mode interference technology, applied in the field of integrated optics, can solve the problems of semiconductor integration, difficulty in preparation, and difficulty in magnetic field integration or packaging, and achieve simplified magnetic field application methods, easy preparation and packaging, and low insertion loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Practical example 1

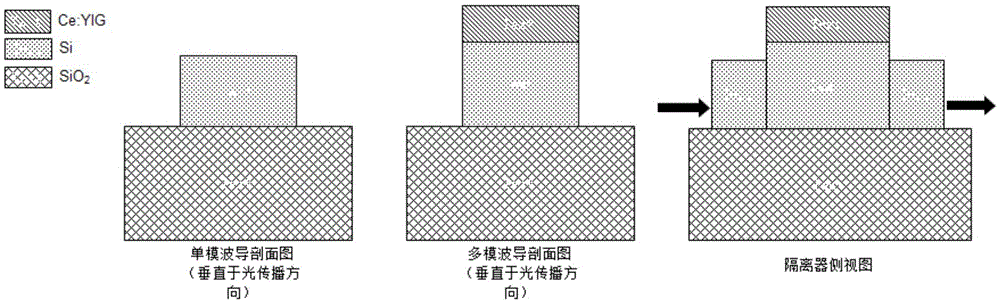

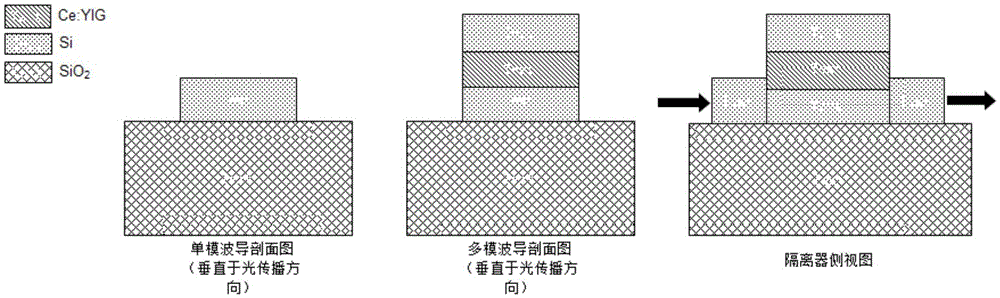

[0026] Such as figure 1 As shown, this structure adopts SOI substrate as the low refractive index layer, and grows magneto-optical thin film layer, low refractive index layer and semiconductor waveguide layer on it to form the device. The low refractive index layer of the single-mode waveguide is SiO 2 , the thickness is 2um, the semiconductor waveguide layer is silicon, the width is 500nm, the thickness is 350nm, and the uppermost low refractive index layer is made of air. In a single-mode waveguide, the propagation of light is limited to one transmission mode, the fundamental mode TM00 of the TM mode and the fundamental mode TE00 of the TE mode.

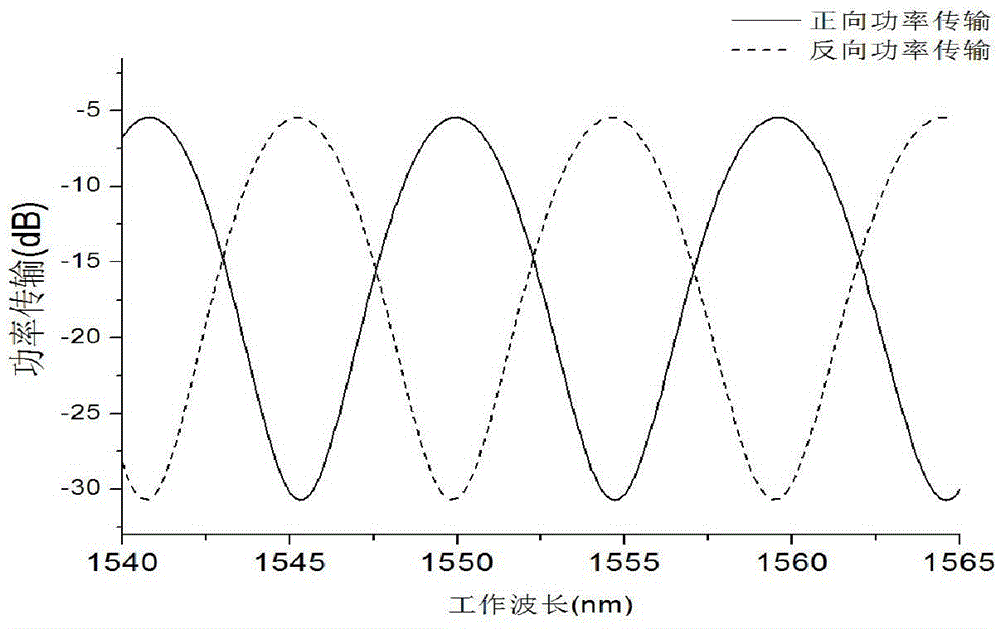

[0027] The second part of the isolator is the first multimode waveguide, the waveguide structure is from bottom to top and the thickness of each layer is SiO 2 (2um) / Si(500nm) / CeYIG(300nm) / air, the waveguide width is 500nm, it supports TM00 mode and TM01 mode. Since the TM00 mode is mainly distribut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com