Train coal density measuring system

A technology of density measurement and train, which is applied in the direction of measuring devices, specific gravity measurement, instruments, etc., can solve the problems of increased difficulty in the prevention and control of corruption risks, backward hardware facilities, loss of benefits, etc., and achieve good coal quality detection effect , convenient quality inspection and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

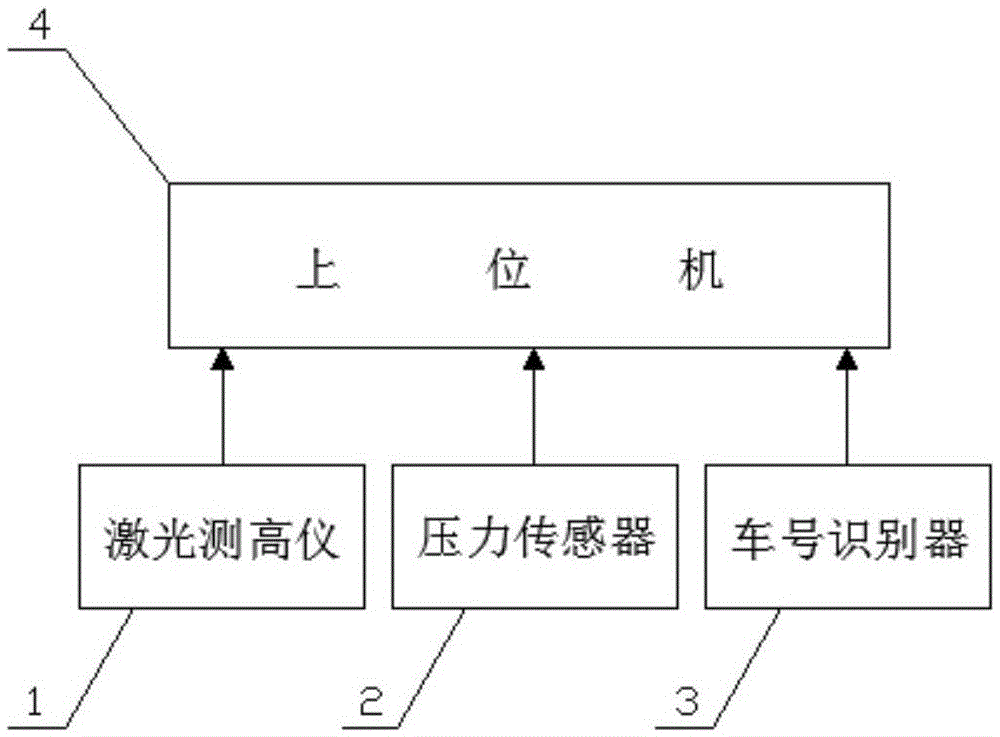

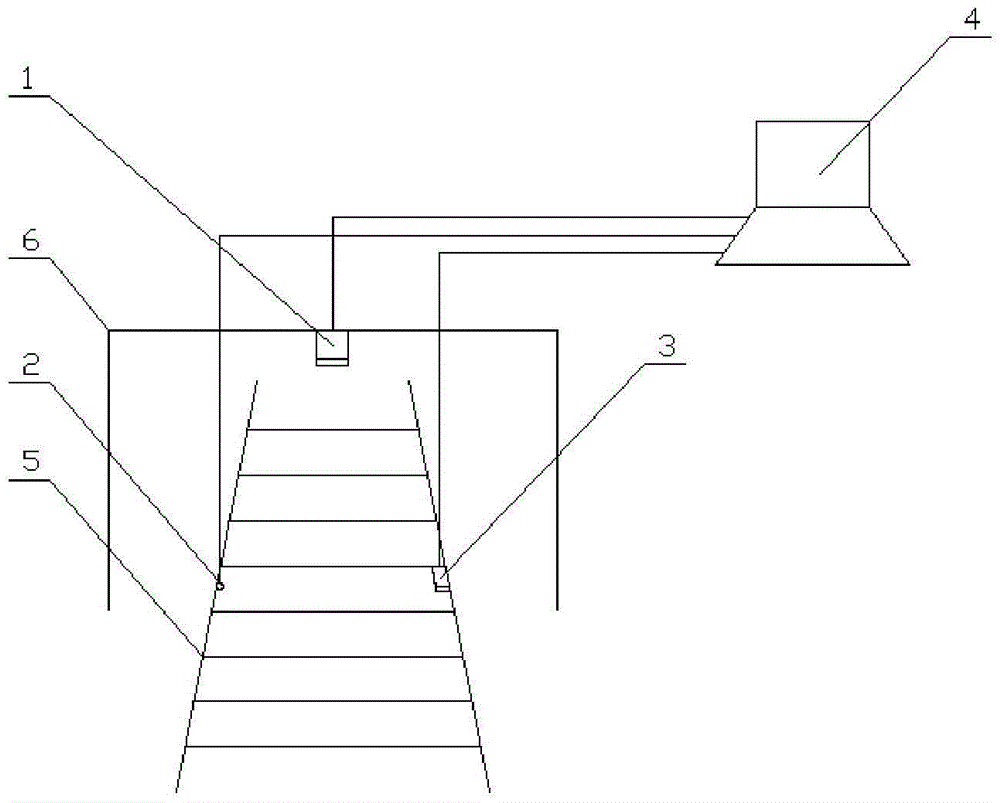

[0017] Such as Figure 1-Figure 2 As shown in the structural diagram of the present invention, the present invention provides a train coal density measurement system, comprising a laser altimeter 1, a pressure sensor 2, a car number identifier 3 and a host computer 4, the laser altimeter 1, the pressure sensor 2. The car number identifier 3 is connected with the host computer 4 respectively, the laser altimeter 1 is used to detect the height of the coal in the train wagon and sends the detected data to the host computer 4, and the pressure sensor 2 is used to detect The total weight of the train wagon is loaded with coal and the detected data is sent to the host computer 4, and the car number identifier 3 is used to identify the specification of the train wagon and send the identified data to the host computer 4.

[0018] The train wagon specifications include the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com