An anti-run water faucet

A faucet and anti-running water technology, which is applied in the field of faucets, can solve the problems of low reliability, poor operation controllability, and cannot be widely promoted, and achieves the effects of preventing running water, novel structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

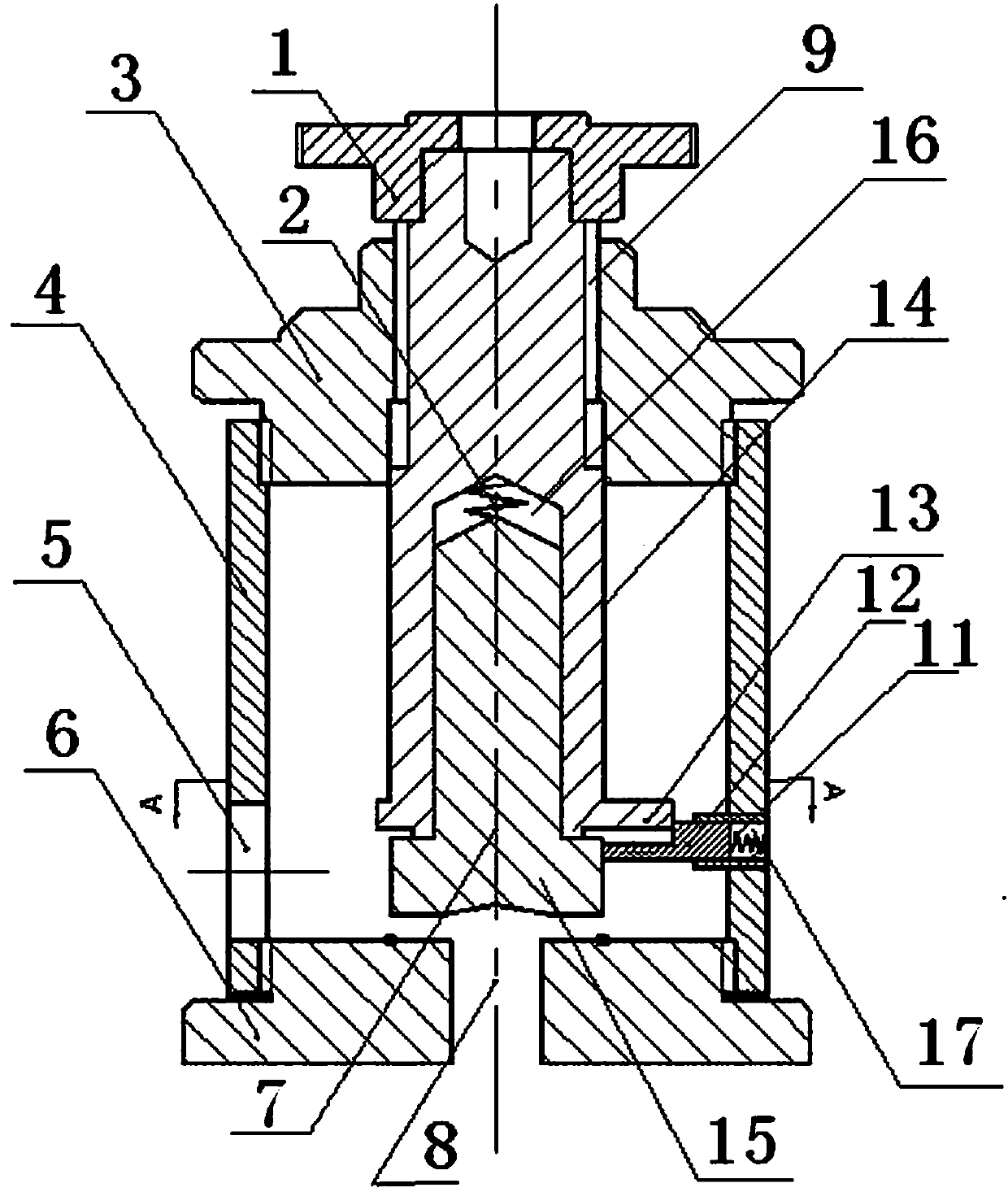

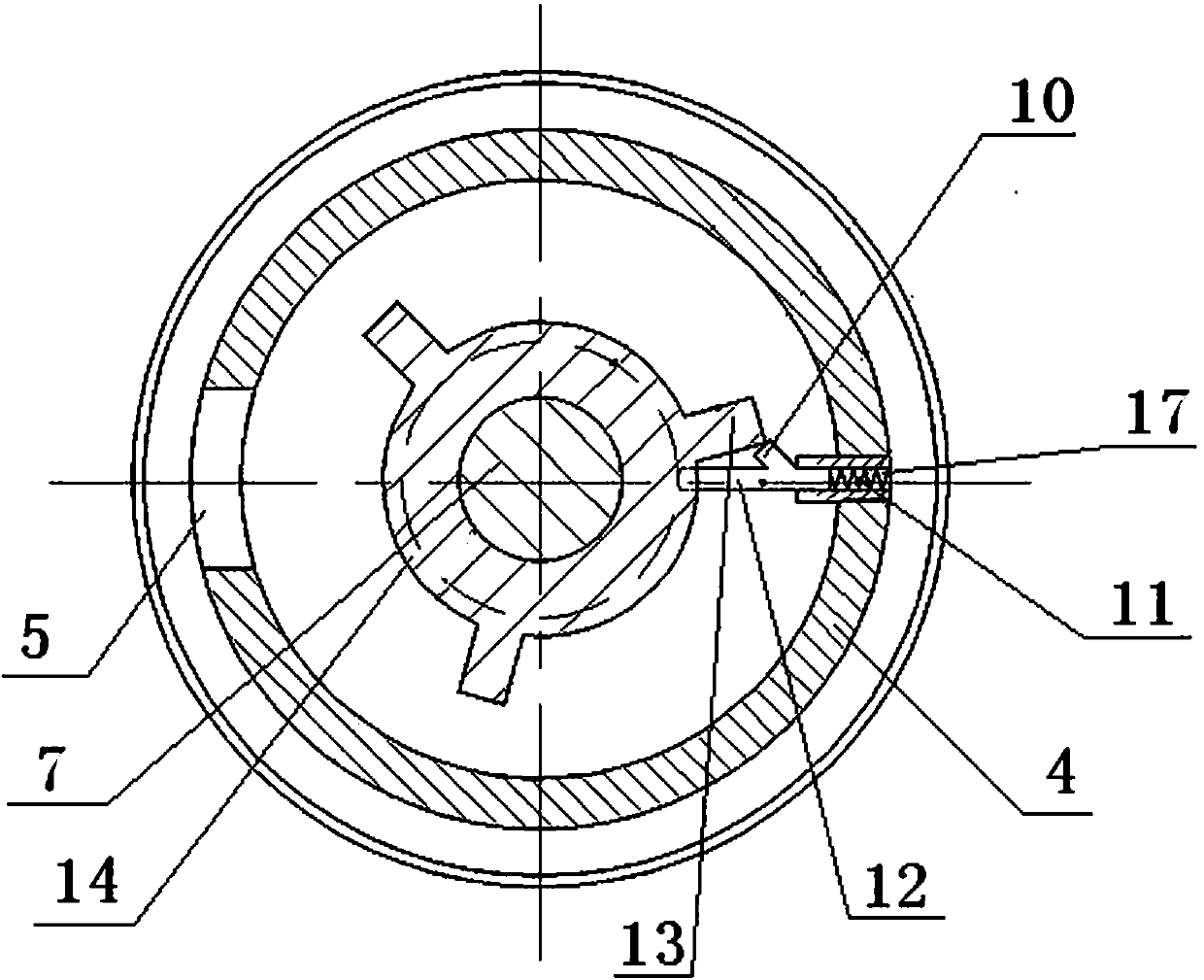

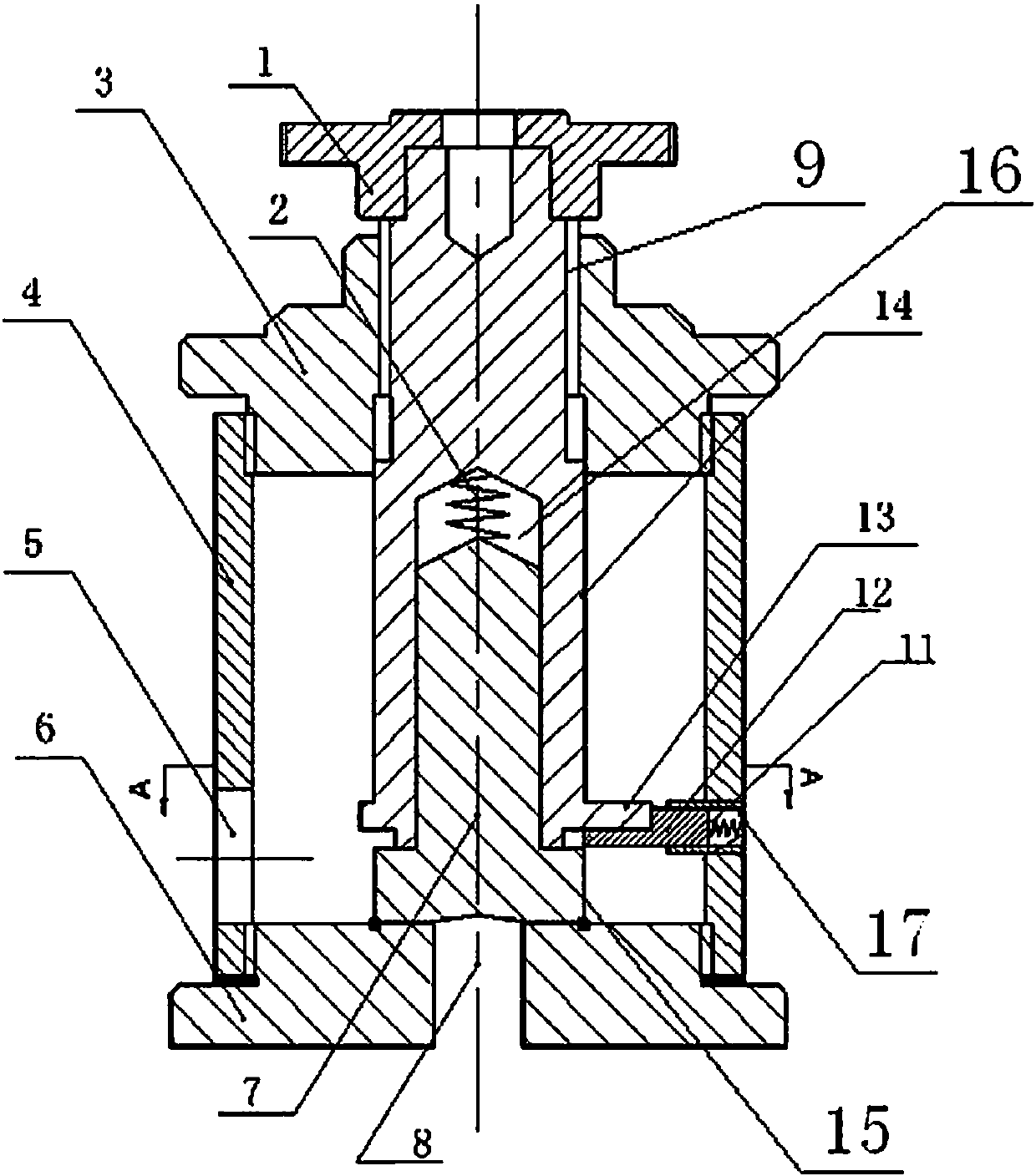

[0018] An anti-running water faucet, comprising a faucet main body and an anti-running water mechanism; the faucet main body includes a valve body 4, a valve core 14, a rotary switch 1, an upper end cover 3 and a bottom cover 6, and the bottom cover 6 has a water inlet 8; the upper end cover 3 and the bottom cover 6 are respectively connected with the inner wall of the upper port and the inner wall of the lower port of the valve body 4 by threads, the valve body 4 is provided with a water outlet 5, the upper end cover 3 has a central hole 9 with internal threads, and the upper part of the valve core 14 has an outer Thread, the upper end of the valve core 14 is connected with the hole wall of the central hole 9 of the upper end cover 3 with threads, the lower part of the valve core 14 is located in the valve body 4, the rotary switch 1 is fixed on the upper end of the valve core 14, and the main body of the faucet is a known technology. It is characterized by:

[0019] The anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com