Magnetorheological-effect-based line-shaped bolt with pretightening force adjusting function

A magnetorheological effect and magnetorheological fluid technology, applied in the directions of screws, threaded fasteners, connecting components, etc., can solve the problems of difficulty in ensuring accuracy and difficult to apply to high-precision mechanical assembly occasions, and achieve high precision, Compact, fast-response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

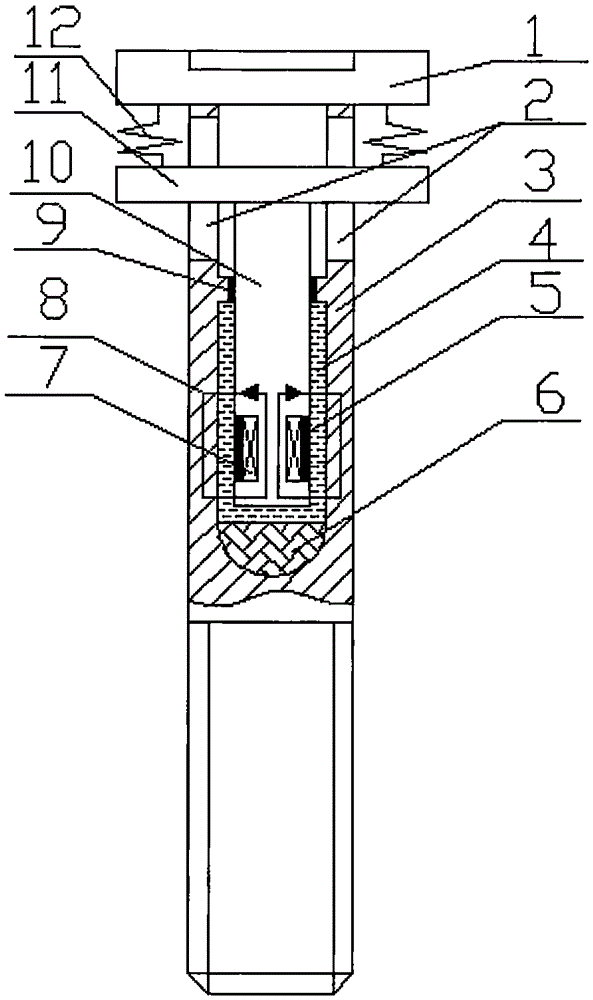

[0011] combine figure 1 with figure 2 , the present invention is based on the magneto-rheological effect and has adjustable pre-tightening function. Device 6, electromagnetic coil 7, sealing ring 9, piston 10, sliding washer 11, return spring 12 are formed. Its internal structure is: there is a chamber in the upper half of the bolt rod 3, the chamber is connected with the outside air through four chute 2 opened on the bolt rod 3, and the sliding washer 11 is connected to the bolt rod 3 through the four chute 2 The sliding pair is established and connected to the bolt head 1 through the return spring 12. There is a groove on the piston 10, and the electromagnetic coil 7 is wound in this groove. The piston 10 is fixedly connected with the sliding washer 11, and the sliding washer 11 drives it to move , the volume compensator 6 is installed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com