Column circuit and control method of a hydraulic support

A hydraulic support and column technology, which is applied in mine roof support, earth square drilling, mining equipment, etc., can solve the problems of reducing the cost performance of the column circuit, improve energy utilization, prevent sheet sides and roof fall, and increase initial support force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

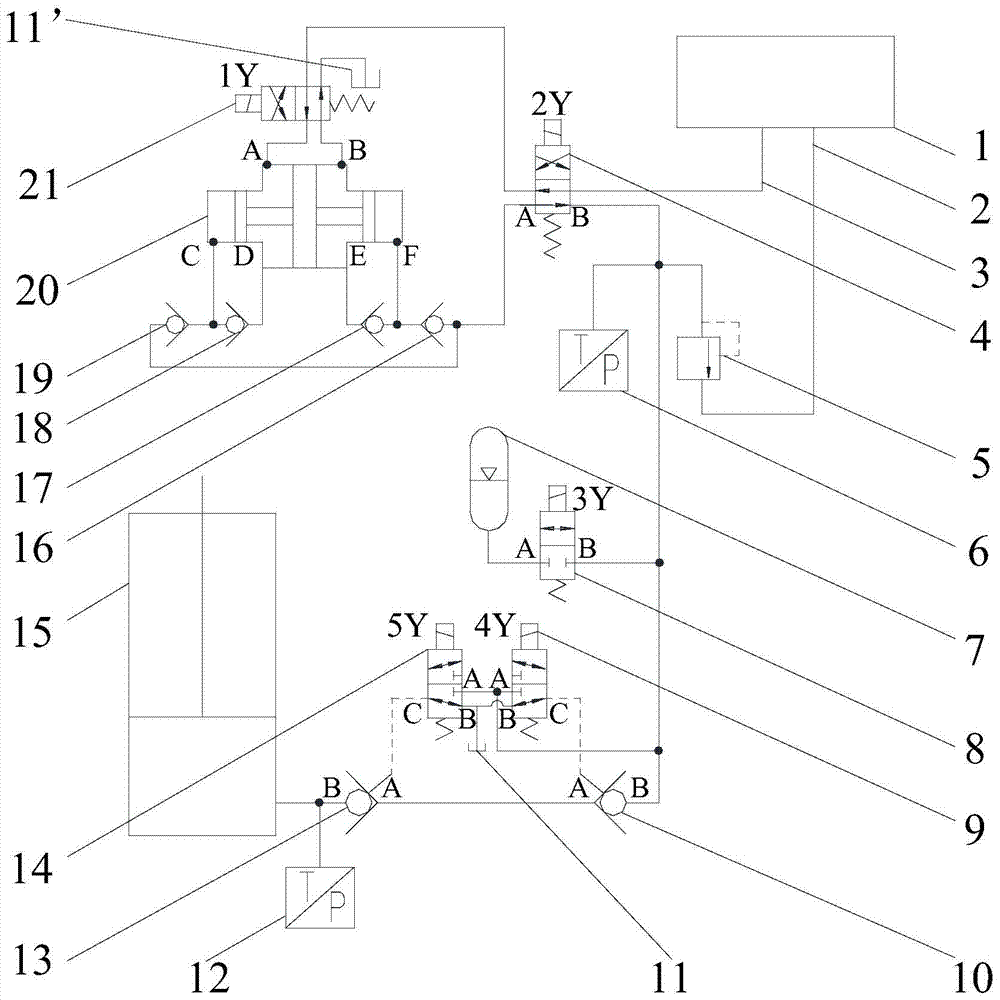

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0016] Such as figure 1 As shown, a column circuit of a hydraulic support, the connection relationship of each component is: the emulsion pump station 1 communicates with the low-pressure liquid return circuit 2 and the main liquid supply circuit 3 respectively, and the main liquid supply circuit 3 passes through the first two-position four-way Valve 4, the second two-position four-way valve 21 communicates with the A port of the booster cylinder 20, and the B port of the booster cylinder 20 communicates with the second liquid storage tank 11' through the second two-position four-way valve 21, and the booster cylinder Port C of 20 communicates with port A of the first two-position four-way valve 4 through the fourth one-way valve 19, and port D of the booster cylinder 20 communicates with the first two-way valve 4 through the third one-way val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com