Dual-purpose powerful waste edge support for mechanical mining and blasting mining

A roof cutting and dual-purpose technology, which is applied to the mine roof support, mining equipment, earthwork drilling and mining, etc., can solve the problems of unworkable face coal mining machines and scraper conveyors, complex support structures, and lateral instability, etc., to achieve improved The effect of initial support force and working resistance, wide range of height adjustment, vertical and lateral stability, and balance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings, so as to further understand the purpose, scheme and effect of the present invention, but it is not intended to limit the protection scope of the claims of the present invention.

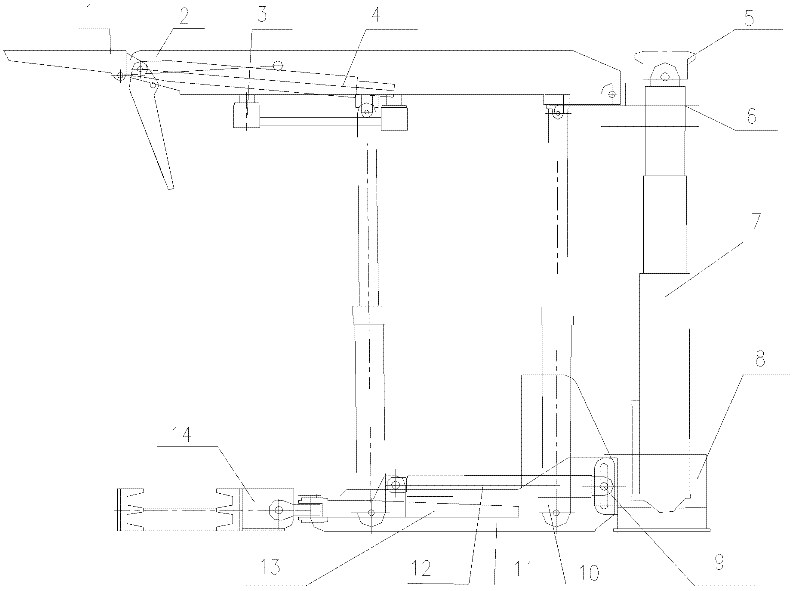

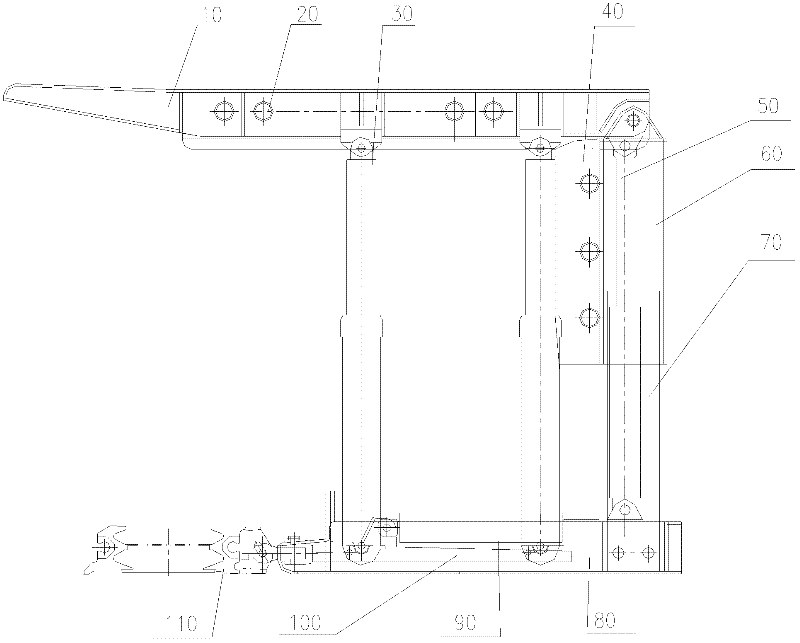

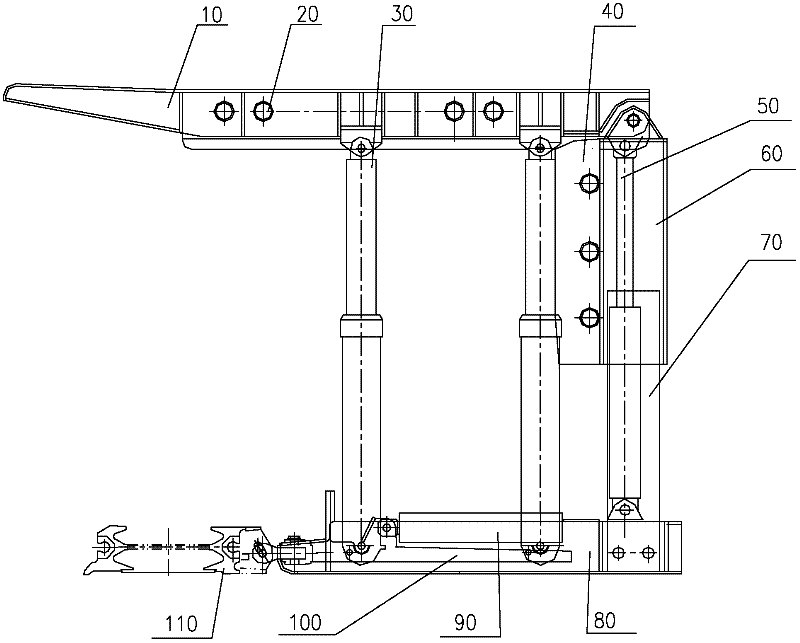

[0018] The invention discloses a dual-purpose powerful roof cutting support for mechanized mining and blast mining, which includes a top beam 10, a top beam side guard plate 20, a hydraulic prop 30, a gangue retaining plate 40, a top cutting balance oil cylinder 50, an upper stabilizing rod 60, a lower stabilizing Rod 70, base 80, push cylinder 90, push rod 100, etc. It is characterized in that: the base 80 and the top beam 10 are supported by hydraulic props 30, and the top beam 10 and the base 80 are provided There is a top cutting balance oil cylinder 50, the upper and lower chambers of the top cutting balance oil cylinder 50 are connected with hydraulic valves, the upper stabilizin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com