Dike and dam superstandard flood flood diversion belt

An ultra-standard, dam technology, applied in water conservancy engineering, hydraulic engineering equipment, construction, etc., can solve the problem of lack of reservoir auxiliary dam flood control and disaster mitigation design theory, and the failure of earth-rock structure dams to resist excessive floods, so as to reduce property losses. , The effect of reducing huge economic losses and saving project investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

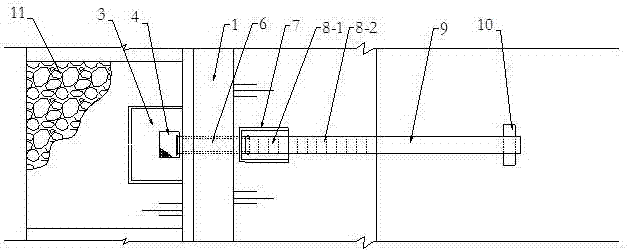

[0033] Example 1: The dam exceeds the standard flood flood diversion pipe belt, the cage trash rack 4 is placed in the imported hafnium U-shaped groove 3, to prevent floating objects from damaging the geosynthetics and blocking the flood diversion pipe, and the HDPE flap door 5 is placed in the cage trash rack In the gate 4, the flood diversion function is controlled, and the HDPE flap gate 5 is fixed on the upstream inlet end of the flood diversion pipe body 6, and the flood diversion pipe body 6 is buried horizontally on the upper part of the embankment 1 to form a pressurized flow, which increases the flood diversion flow of the unit passing section, and the flood diversion pipe The upstream outlet end of the body 6 is located in the imported hafnium U-shaped groove 3 and the cage trash rack 4, the downstream outlet end of the flood diversion pipe body 6 is placed in the outlet hafnium U-shaped groove 7, and the downstream outlet end of the flood diversion pipe body 6 is arti...

Embodiment 2

[0045] Example 2: During temporary flood diversion for flood fighting and emergency rescue, if the water depth is small or there is no HDPE gate, use barbed wire to tie the inlet end of the flood diversion pipe body 6 as a cage trash rack 4, and use sandbags + non-woven fabrics + iron wires to retain soil or pipes The body protrudes from the upstream slope to replace the inlet U-shaped groove 3, and the flood diversion pipe body 6 protrudes from the downstream embankment slope to replace the outlet U-shaped groove 7 of the flood diversion pipe body 6. If it is necessary to stop flood diversion, it is placed in front of the cage trash rack 4 Strip cloth pressure sandbags replace HDPE flap door 5, others are the same as above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com