Anodes for external plating of engine block tanks

An engine block and anode technology, applied to electrodes and other directions, can solve the problems of difficult control of key dimensions, difficulty in quality assurance of finished products, large changes in coating thickness, etc., to achieve controllable changes in coating thickness, avoid burrs on the edge of the coating, stable and uniform The effect of liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

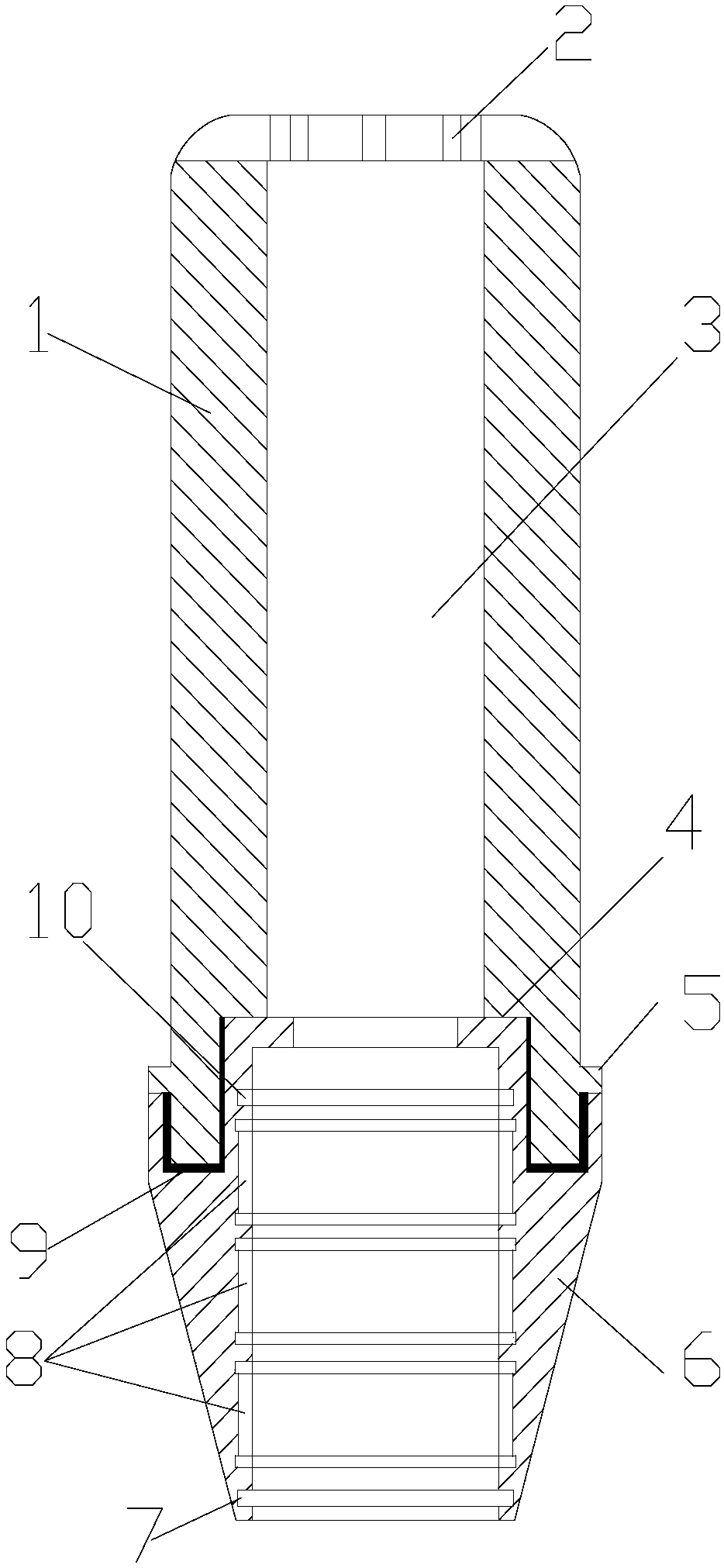

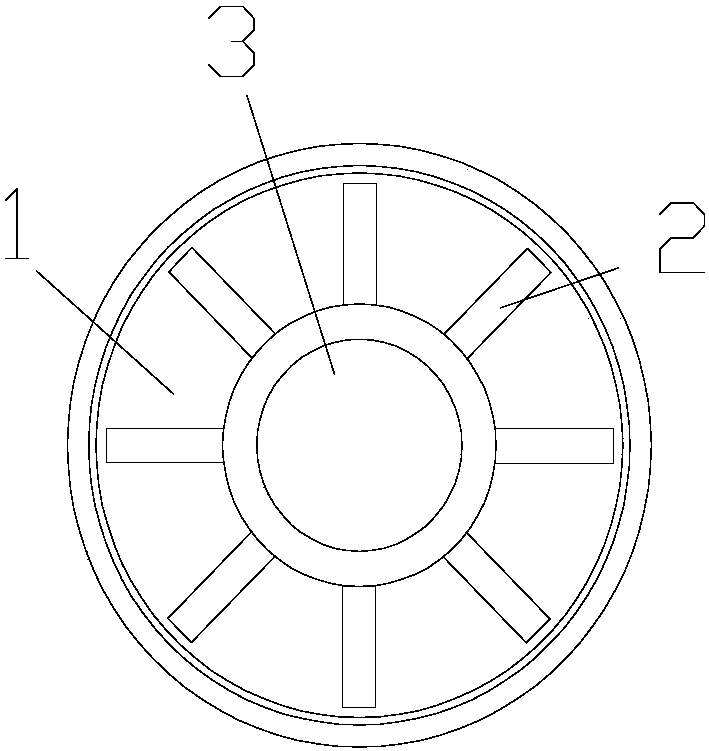

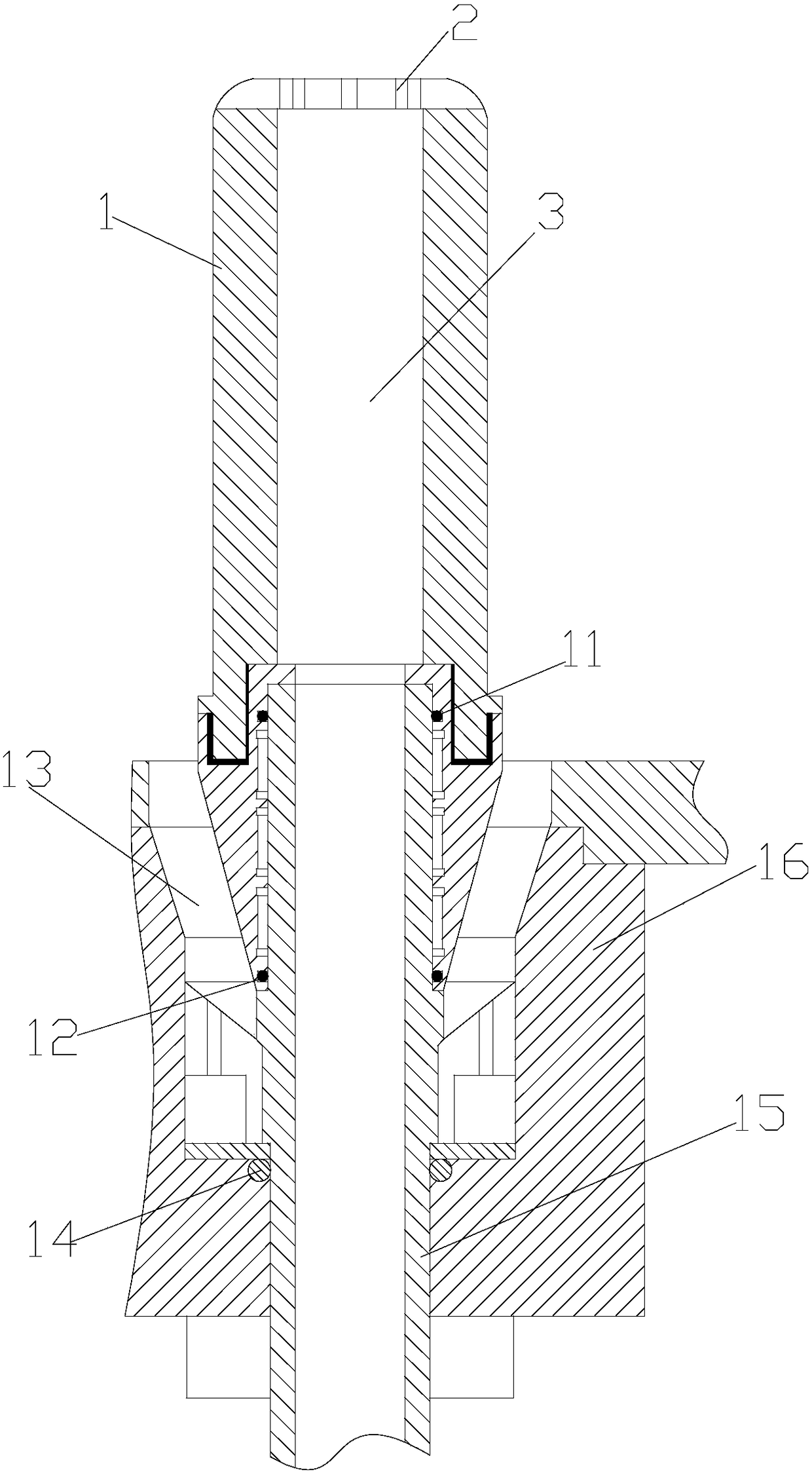

[0019] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 top view, image 3 Use the installation structure diagram for the present invention, as shown in the figure: the anode used for electroplating outside the engine cylinder tank of this embodiment includes an anode body 1, and an electroplating solution return channel 3 is provided through the anode body 1, and the anode body 1 When in use, it is set inside the cylinder body, and the electroplating solution flows through the annular gap between the outer surface of the anode body 1 and the inner surface of the cylinder for backflow by the electroplating solution return channel 3 after electroplating; when in use, the anode itself 1 is generally fixed and Conductively connected to an anode seat 6. The anode seat 2 is directly installed on an installation base 16. Of course, the anode seat body can also be directly formed by integral molding, and the anode seat body is directly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com