Sorting and turning device for autoclaved aerated plates

A technology of turning device and autoclaved sand, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of large volume, difficult to detect and repair, hidden dangers, etc., and achieve the effect of safe operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

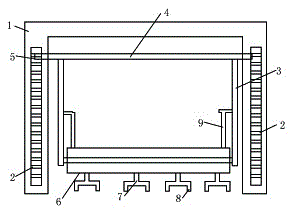

[0012] Combine below figure 1 Specific description embodiment:

[0013] Such as figure 1 As shown, the autoclaved sand aerated plate sorting and turning device includes a frame 1, the two sides of the frame 1 are provided with racks 2, and the frame 1 is connected with a clamp turning frame 3, The upper part of the clamp turning frame 3 is an upper shaft 4, and the two ends of the upper shaft 4 are provided with gears 5, and the gear 5 is meshed with the rack 2 on the frame 1, and the clamp turning frame 3 The movement in the vertical direction can be done on the frame 1 driven by the motor; the lower part of the clamp turning frame 3 is hingedly connected with a clamp assembly 6, and the clamp assembly 6 is composed of several groups of clamp units 7. The unit 7 includes two correspondingly arranged mechanical splints 8, the two mechanical splints 8 can be clamped or loosened under the drive of the cylinder, and the two ends of the clamp assembly 6 are provided with hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com