Transfer machine for box girder side form

A side form and box girder technology, which is applied in the field of box girder side form transport trolleys, can solve the problems of narrow space in the enclosure, large transfer costs, narrow construction space, etc., and achieve the effect of ensuring construction progress and safe and fast transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

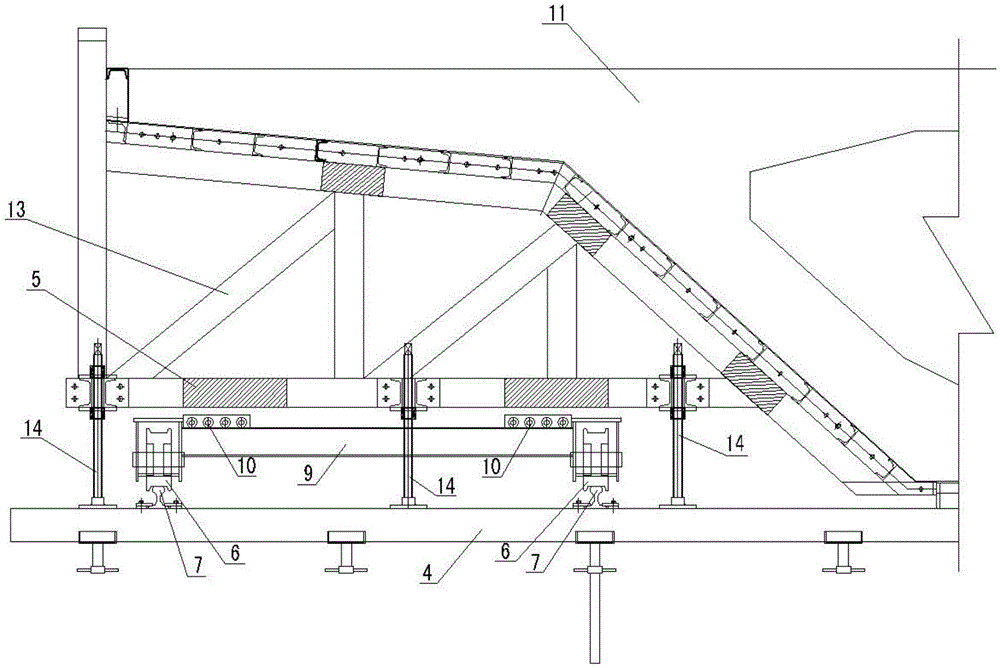

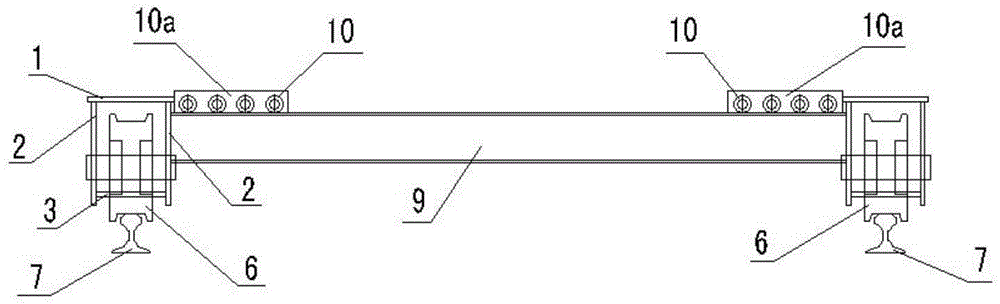

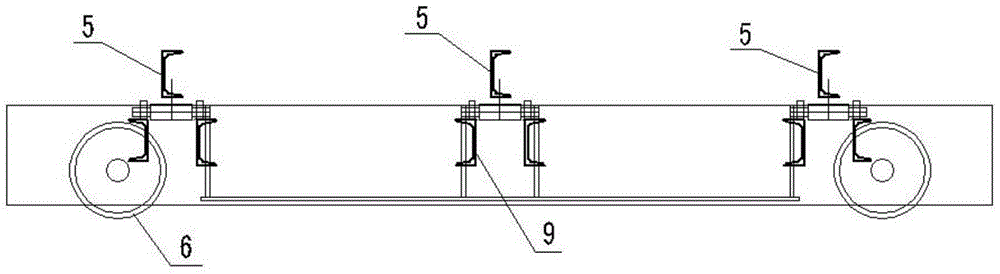

[0016] see figure 1 In this embodiment, the structural form of the box girder side form transfer tool for the box girder 11 is: on the support platform 4 below the box girder side form 13, two tracks are arranged in parallel along the direction of the transfer of the box girder side form 13 7. The traveling steel wheels 6 on both sides of the steel frame trolley are respectively supported on the track 7 at the corresponding position and can roll along the track. Rollers 10 are arranged in rows on the beam 9 of the steel frame trolley. The axes of the rollers 10 are Parallel to the track 7, and the roller 10 can roll on a fixed axis; the dropped box girder side form 13 can be supported on the roller 10 by the lower gusset plate 5 of the box girder side form, and the box girder side form 13 can be supported by the roller 10 The whole body moves to the outside for a certain distance on the steel frame trolley and then transfers on the track 7 with the steel frame trolley.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com