Self-adaptation follow-up carton packaging machine

A self-adapting, packaging machine technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of inconvenient work in different locations, packaging of different sizes of cartons, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

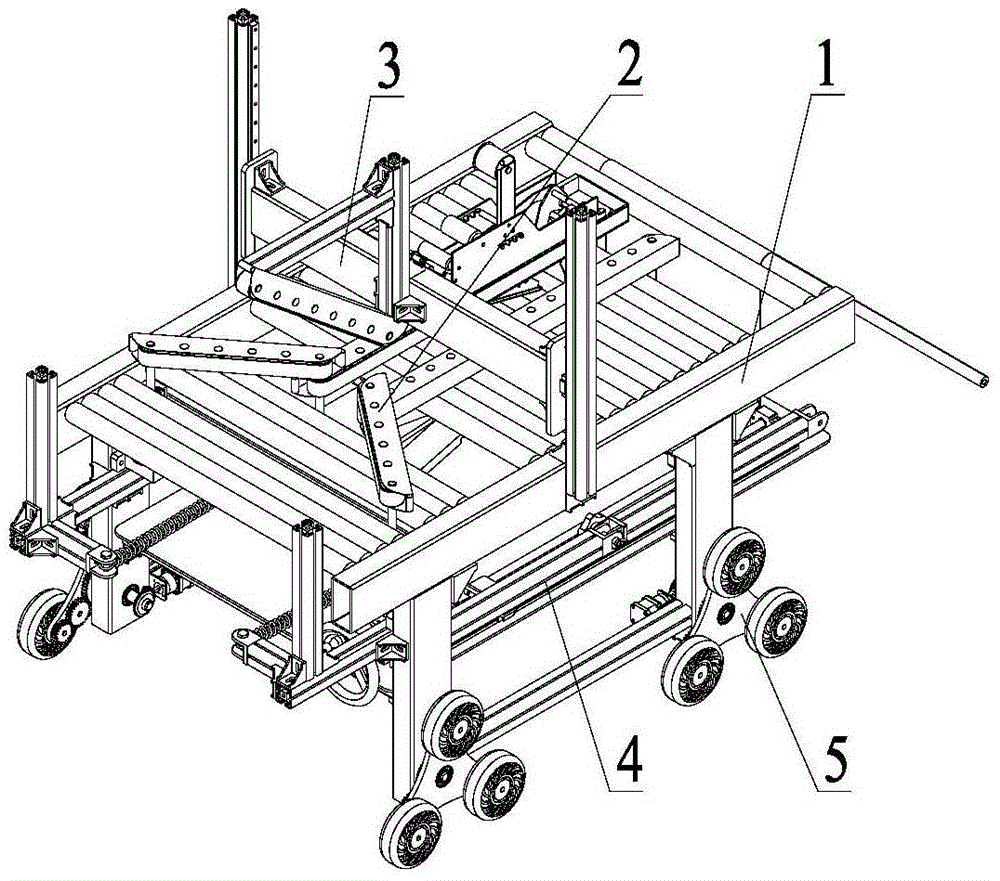

[0025] See attached figure 1 , the self-adaptive follow-up carton sealing machine of the present invention comprises:

[0026] A truss platform 1, a row of rolls is mounted on the truss platform 1;

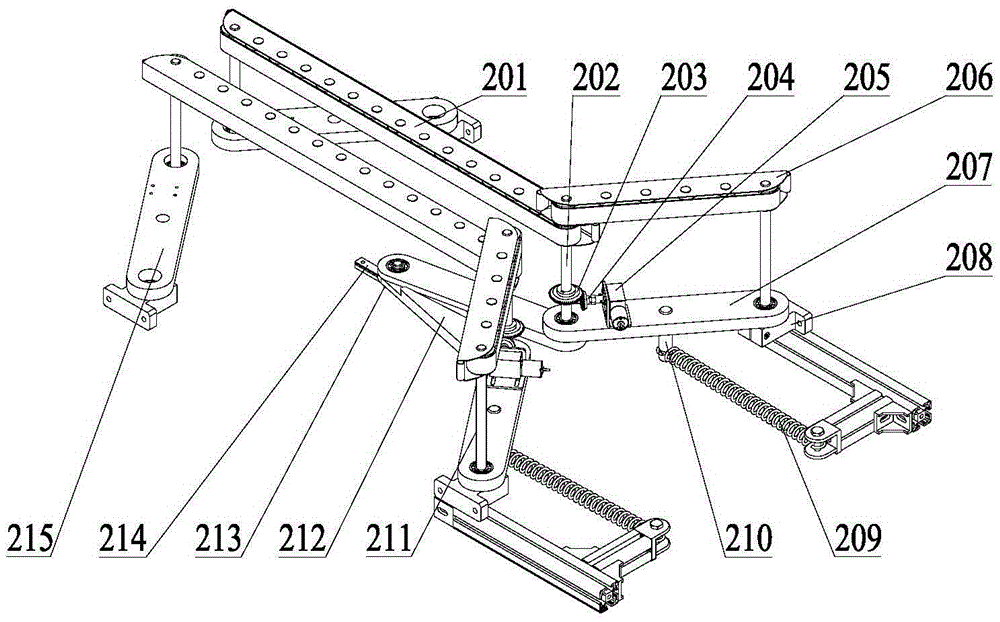

[0027] Two groups of follow-up parallelogram mechanisms 2 symmetrically arranged on the rollers of the truss platform 1, and two groups of parallelogram mechanisms are oppositely provided with conveyor belts;

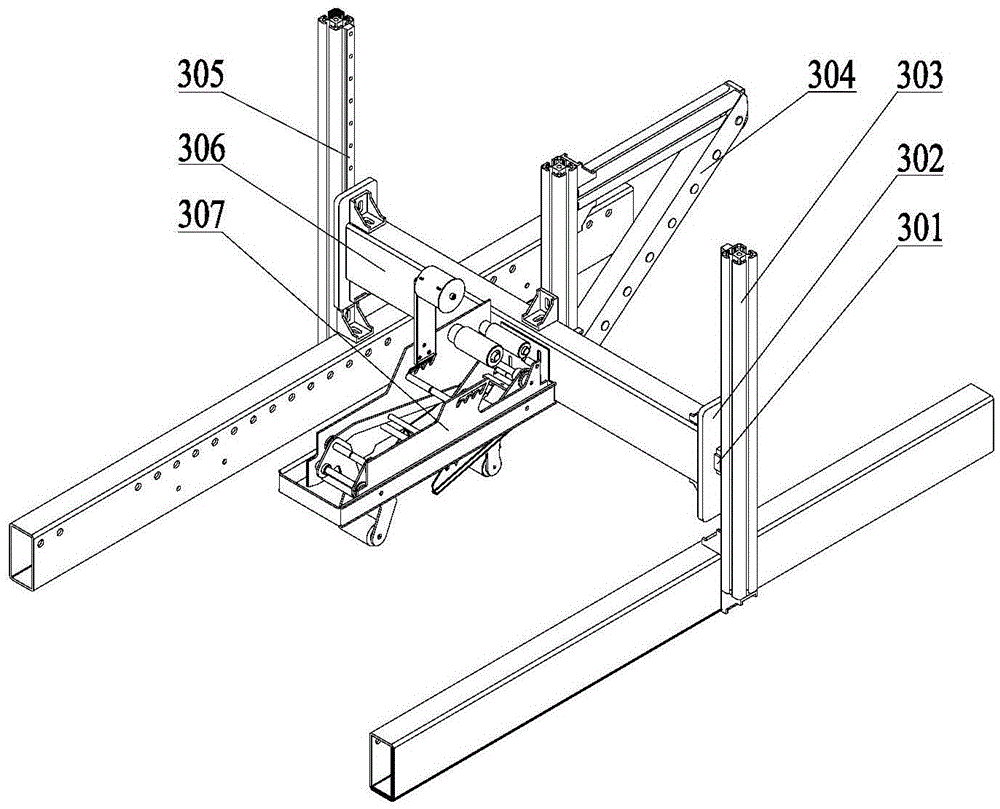

[0028] See attached image 3, the gear rod frame 3 fixed on the truss platform 1, the gear rod frame 3 includes a slider II 301, a slider II connecting block 302, a guide rail II support frame 303, a gear rod 304, a guide rail II 305, and a support beam 306 and tape wrapping mechanism 307; two guide rail II support frames 303 are relatively vertically fixed on both sides of the truss type platform 1, and guide rail II 305 is vertically arranged ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com