Sausage feeding machine

A feeder and sausage technology, which is applied in the field of sausage feeder, can solve problems such as low efficiency, failure to meet production requirements, and difficult control of sanitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

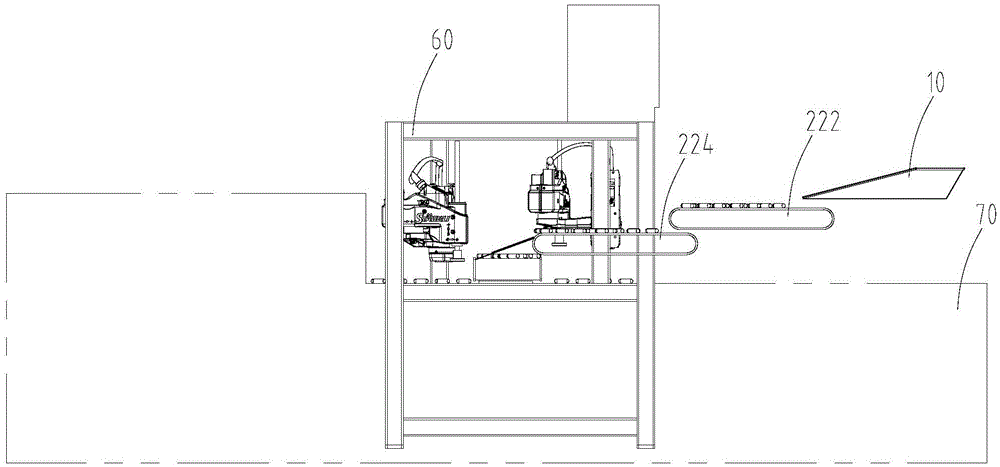

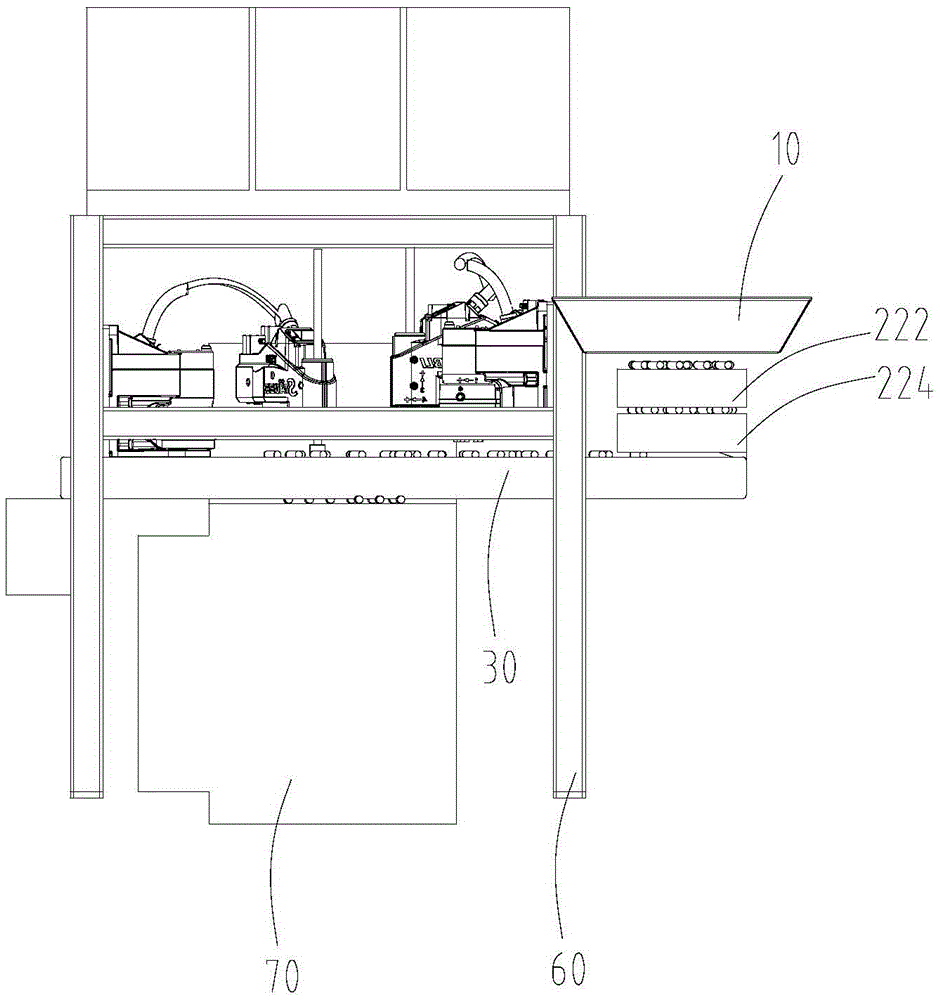

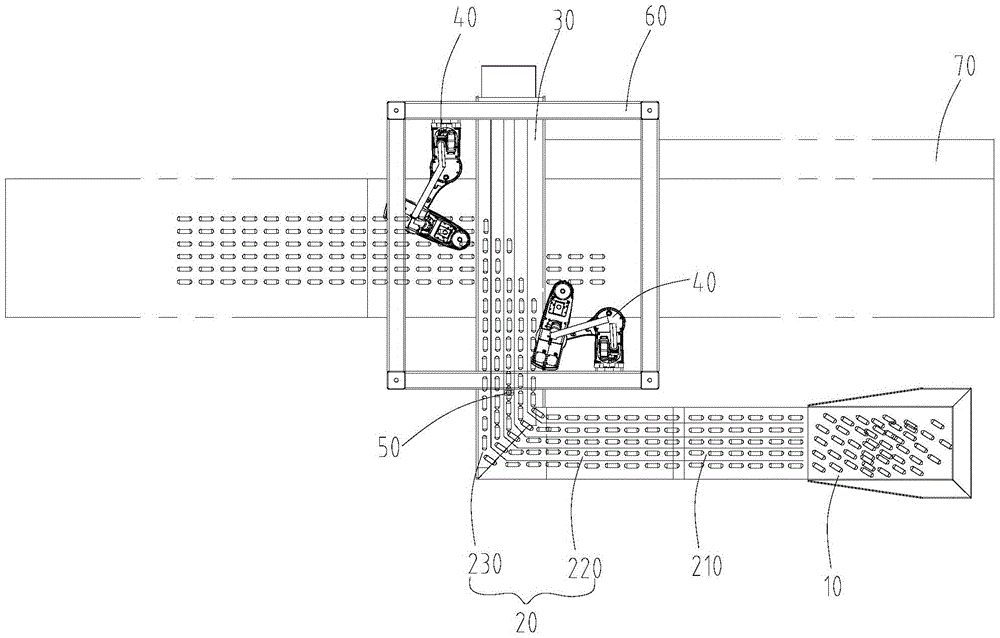

[0021] like Figures 1 to 3 As shown, a sausage feeding machine includes a vibrating hopper 10, a vibrating conveyor belt 20, a grabbing conveyor belt 30, two robots 40 and a vision mechanism 50, the head end of the vibrating conveyor belt 20 is docked with the vibrating hopper 10, The end of the vibrating conveyor belt 20 is docked with the grab conveyor belt 30, the visual mechanism 50 is arranged above the grab conveyor belt 30, two robots 40 are respectively arranged on both sides of the grab conveyor belt 30, and two The robot 40 is arranged diagonally to the grasping conveyor belt 30 , and the vision mechanism 50 is electrically connected to the robot 40 . The electrical connection refers to connection through wires or wireless signal connection.

[0022] When feeding, pour a basket of sausages into the vibrating hopper 10, the vibrating hopper 10 vibrates the sausages evenly, and transports them to the vibrating conveyor belt 20, and the vibrating conveyor belt 20 furt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com