Method for building scaffolds in closing stage of bottom side tank of bulk cargo ship cargo hold

A technology for scaffolding and hopper tanks, which is applied in construction, shipways, dry docks, etc. It can solve the problems of time-consuming and labor-intensive building and dismantling, many materials, damage to ship paint, etc., to save time and effort for installation and dismantling, and improve economic efficiency. Benefits, the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

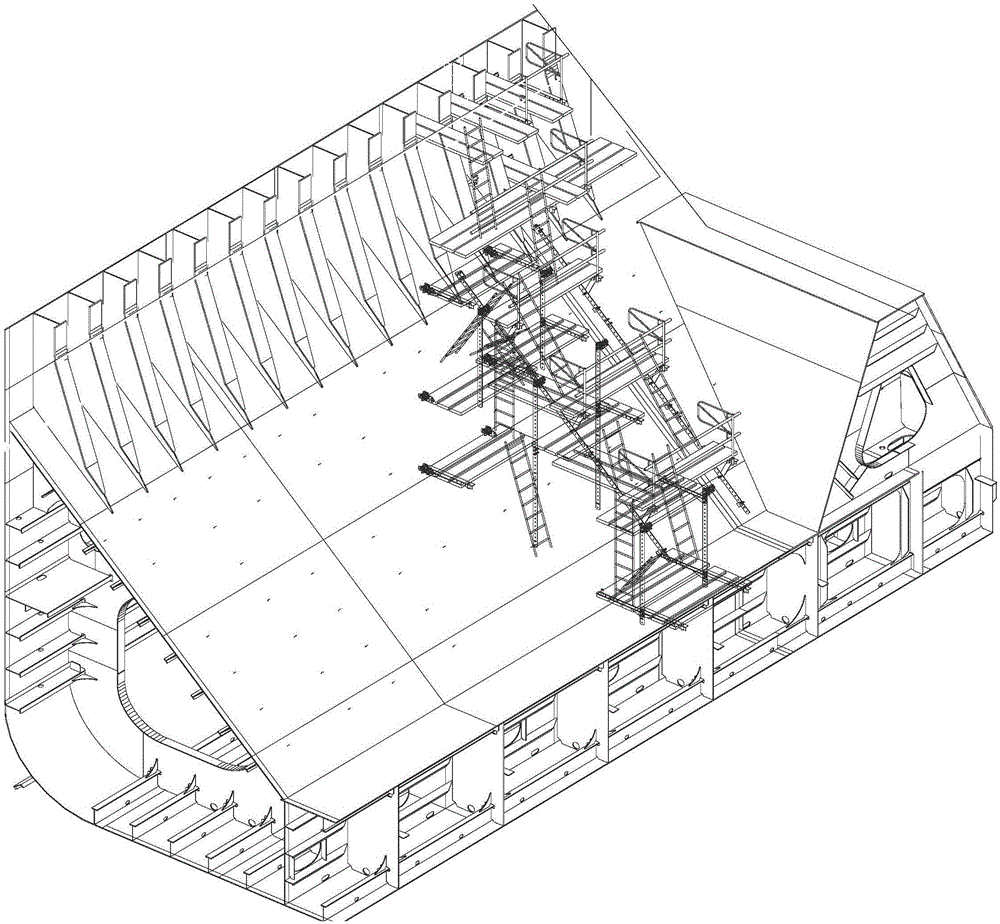

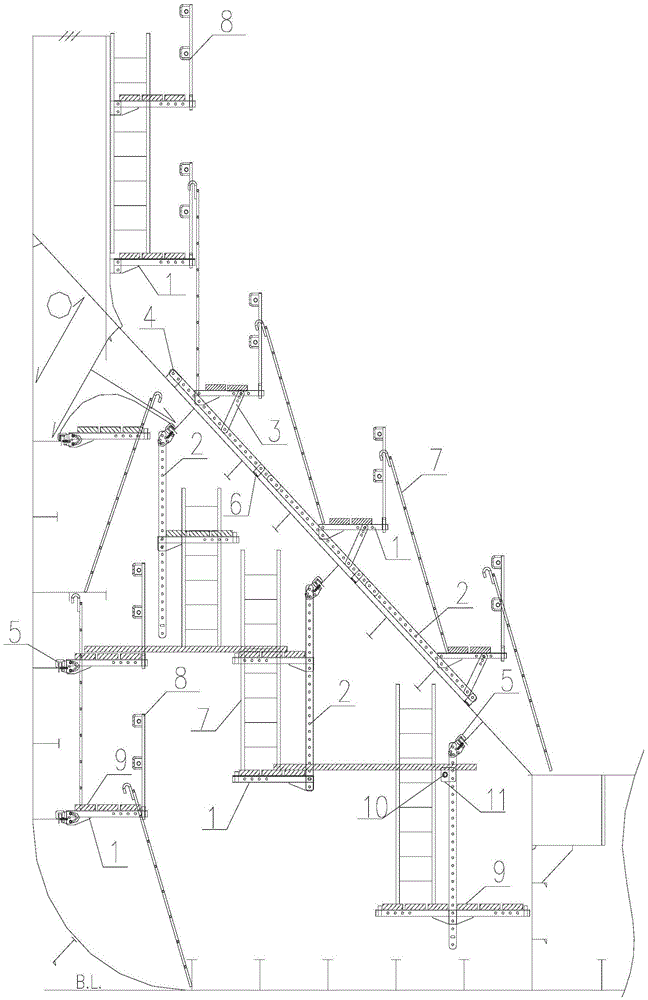

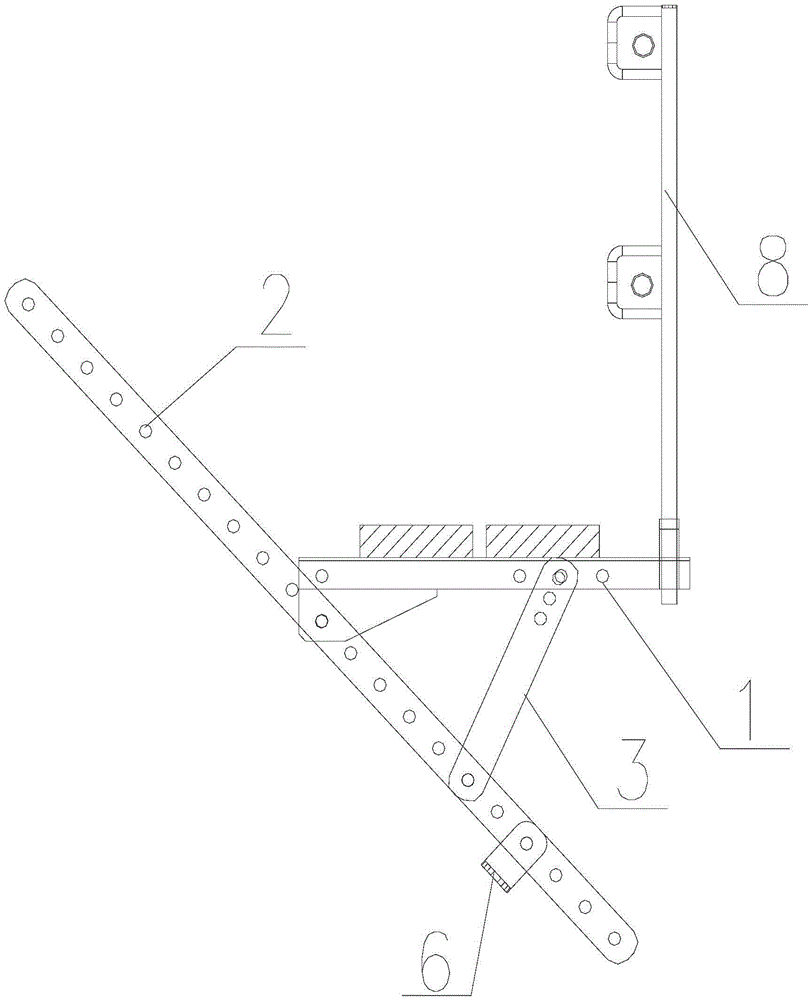

[0022] It is illustrated and explained by illustrating a schematic diagram of the scaffolding arrangement in the cargo hold closing stage of a 180,000DWT single-hull bulk carrier. These embodiments are given by way of example only with reference to the drawings, without thereby limiting the scope of the present invention to these embodiments.

[0023] Such as Figure 1-5 As shown in the present invention, a method for building scaffolding at the stage of closing the hopper tank of a bulk carrier includes scaffolding supports 1, flat steel connecting bars 2, flat steel diagonal braces 3, scaffolding eye plates 4, and angle-changing scaffolding Fixture 5, support pad 6, scaffolding ladder 7, protective railing 8, galvanized sheet 9, load-bearing steel pipe 10, connecting eye plate 11 and other technical features.

[0024] A method for building scaffolding in the closing stage of the cargo hold hopper tank of a bulk carrier according to the present invention, the closing seams i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com