Rerailing method of railway vehicle

A technology for rail vehicles and vehicles, which is applied to equipment fixed to the rails, railway car body parts, transportation and packaging, etc., can solve the problems of long waiting period, high work intensity, low efficiency, etc., to reduce labor intensity, improve Rerailing efficiency and the effect of reducing the height of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

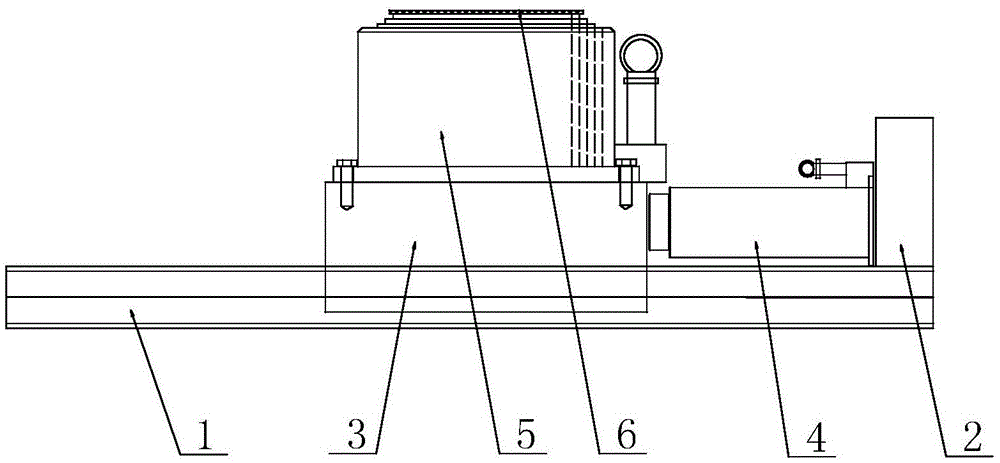

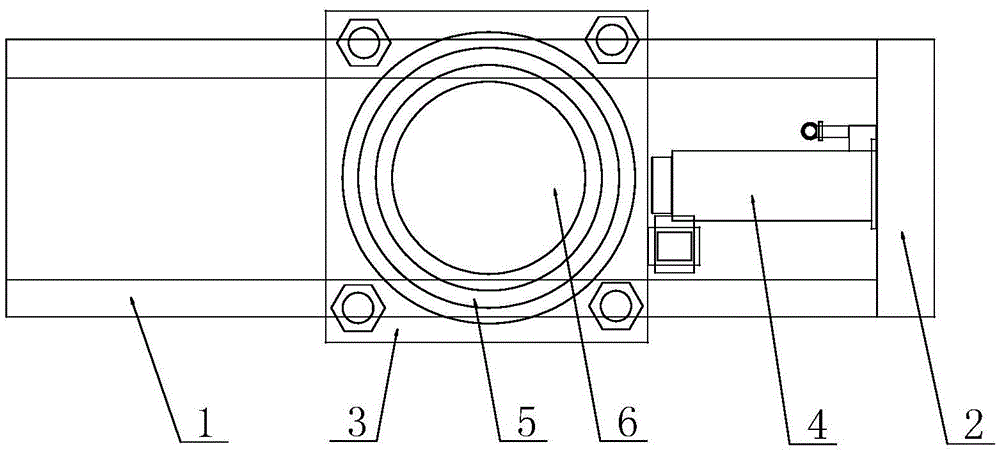

[0020] Such as figure 1 , figure 2 As shown, the rerailing device used in the rerailing method of the embodiment of the present invention. The device comprises: a slide rail 1, a rear stopper 2 fixed on the rear end of the slide rail 1 and a slider 3 arranged on the slide rail 1, the rear stopper 2 is equipped with a first manual for pushing the slider 2 forward The jack 4 and the top of the slider 3 are fixed with a second manual jack 5 for jacking up the side frame of the bogie, and an anti-skid pad 6 is arranged on the top of the second manual jack 5 . In this embodiment, the first manual jack is a manual 10T mechanical jack; the second manual jack is a manual 13T multi-stage hydraulic jack. The second jack is fixed on the slider 3 by bolts.

[0021] Embodiment retracking method steps are as follows:

[0022] 1. Place two sets of rerailing devices under the two side frames of the bogie of the derailed vehicle, so that the slide rails are perpendicular to the rails;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com