Concrete wet-hot curing system

A damp-heat curing and concrete technology, applied in ceramic molding machines, manufacturing tools, etc., can solve problems such as insufficient 28d strength of concrete, improve heat exchange efficiency, reduce air concentration, and overcome the slow heating rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

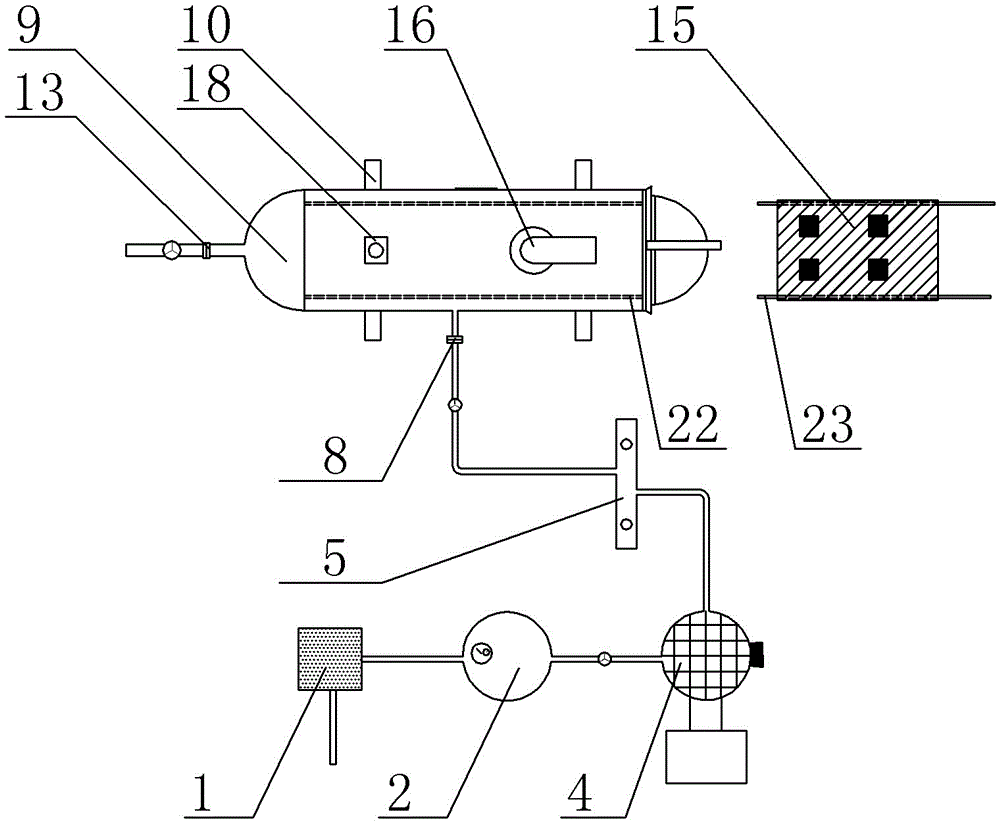

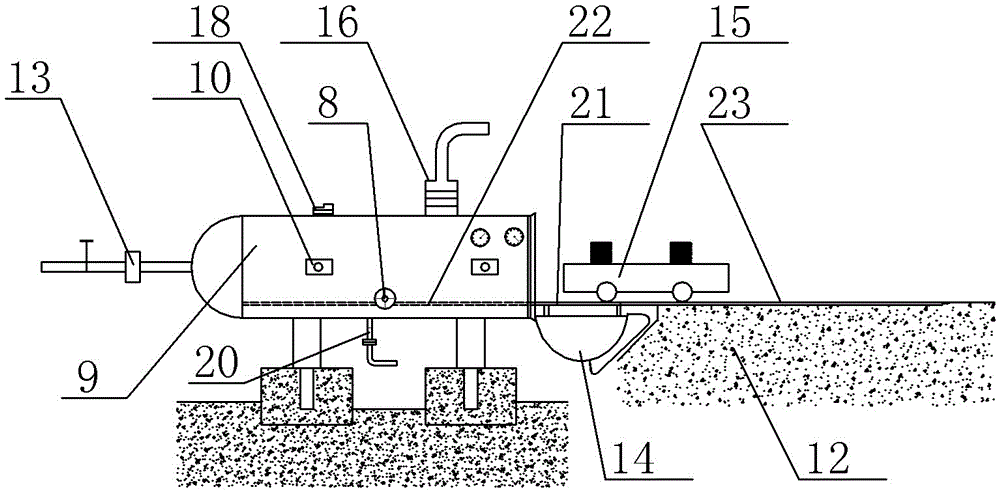

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0017] like figure 1 and figure 2 As shown: the present invention provides a concrete damp heat curing system, including a horizontally arranged reactor 9, the main body of the reactor 9 is a metal steel cylinder, one end of which is closed, and the other end is provided with an openable end cover 14, the end cover 14 The lower part is hinged with the metal steel cylinder, and the side wall of the reaction kettle 9 is provided with a steam inlet 8, an exhaust port 13, a vacuum pump 16, a drain outlet 20, a microwave heater 10, and a loading vehicle 15 arranged in the reaction kettle 9 to enter and exit The inner track 22 of the end cover 14 is provided with a connecting track 21, the rotation plane of the connecting track 21 overlaps with the inner track 22, and a support seat 12 is provided under the end cover, and the support seat 12 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com