Plate pressing ruler chuck and non-chuck integrated rotary cutting machine

A technology of rotary cutting machine and board pressure ruler, which is applied in the manufacture of veneer, wood processing equipment, manufacturing tools, etc., which can solve the problems of poor quality of veneer, achieve uniform thickness of veneer, high finish, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

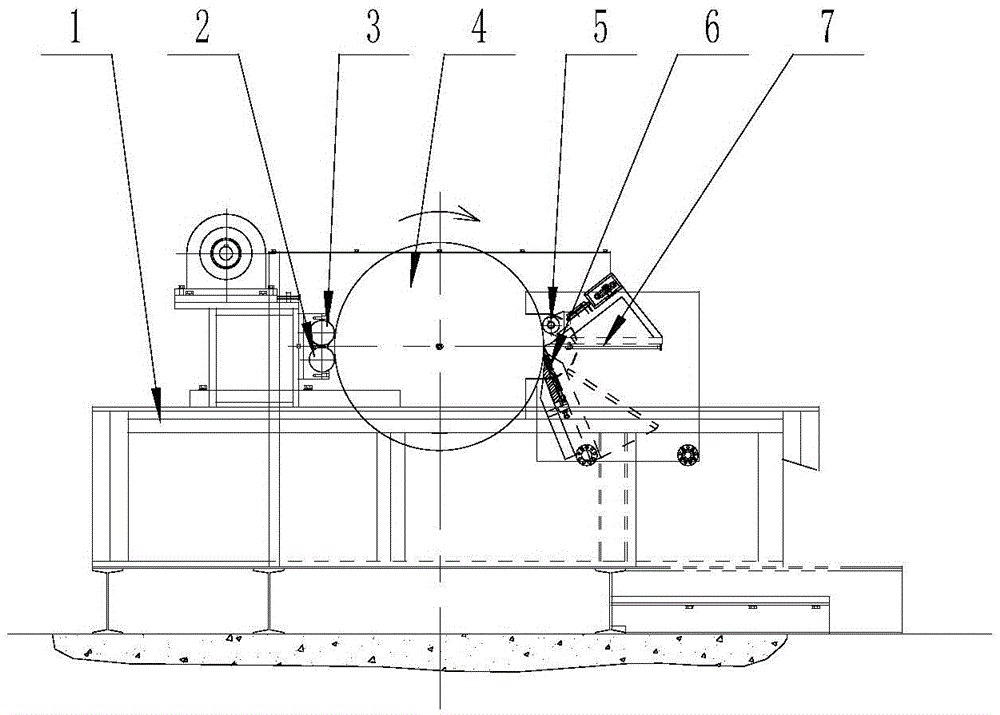

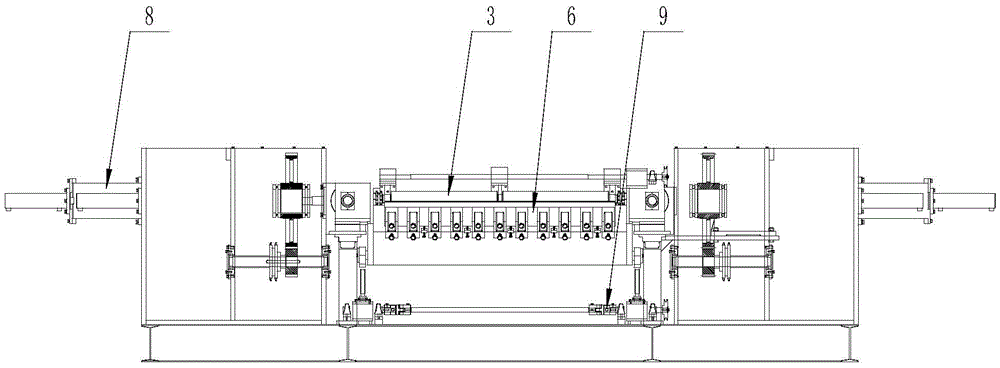

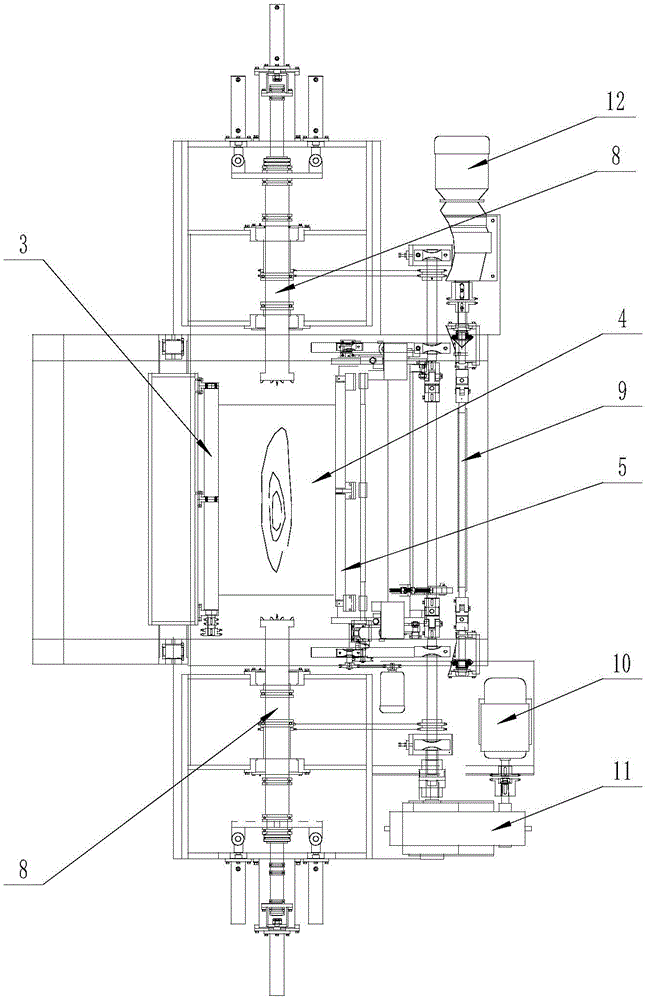

[0016] Such as Figure 1 to Figure 3 As shown, a rotary cutting machine with a card and no card with a plate pressure ruler includes a frame 1, and a positioning drive mechanism, a feed mechanism, a rotary cutter assembly 6 and a plate pressure ruler assembly 7 are arranged on the frame 1, and the positioning drive The mechanism includes a roller driving mechanism and a chuck driving mechanism 11. The roller driving mechanism includes a first driving roller 2, a second driving roller 3 and an auxiliary roller 5 distributed in a triangular structure; a plate pressure gauge assembly 7 is arranged below the auxiliary roller 5, The chuck driving mechanism 11 is connected with two chuck clamping assemblies 8 whose spacing can be adjusted longitudinally, and the chuck driving mechanism 11 is connected with the first driving motor 10 . The roller surfaces of the first driving rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com