Chemical material mixing device

A mixing device and chemical technology, applied in the directions of mixers, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of increasing production costs, increasing the labor intensity of workers, and the mixing device does not have automatic cleaning functions, etc. The effect of production cost, labor intensity reduction and production efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

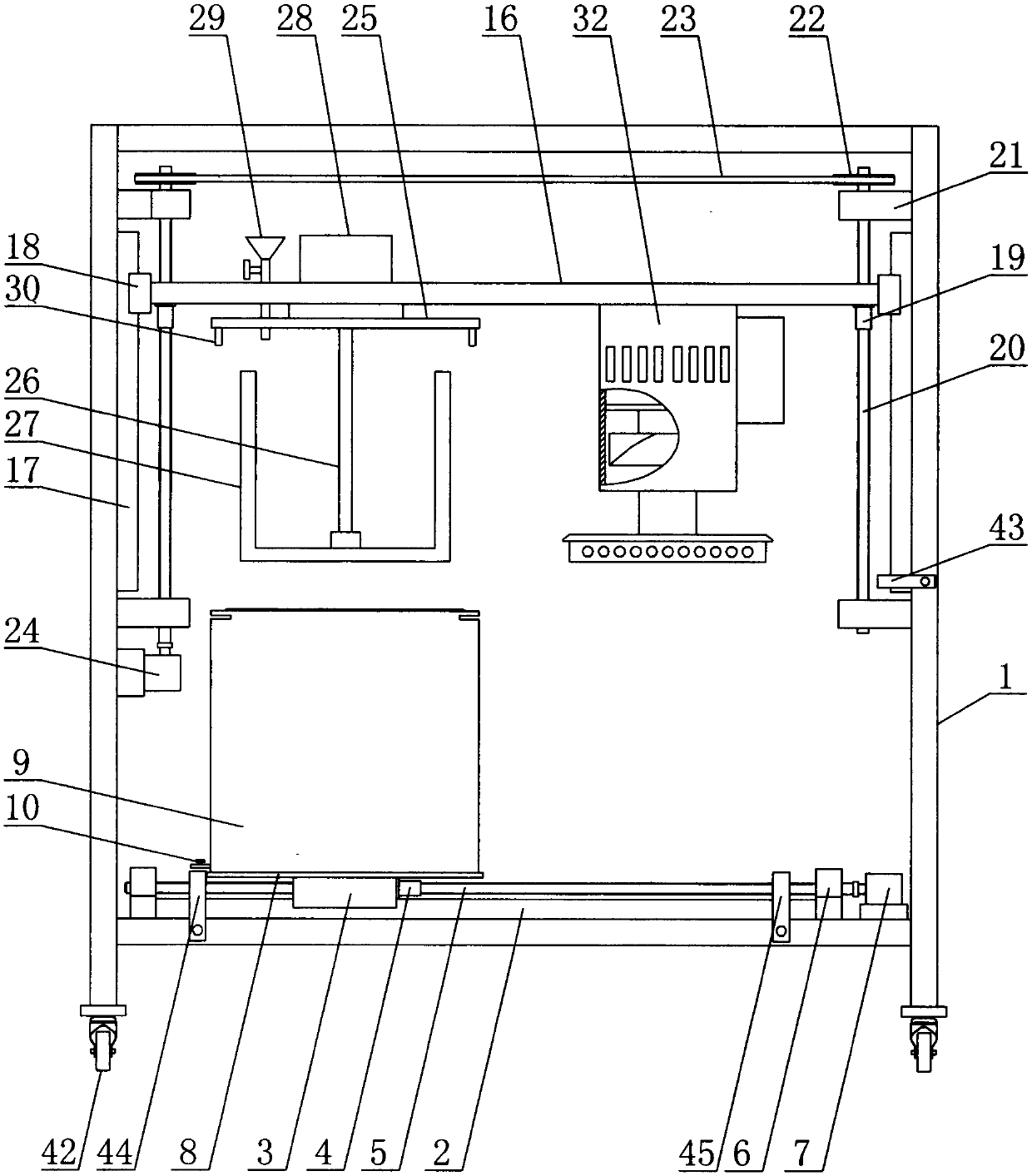

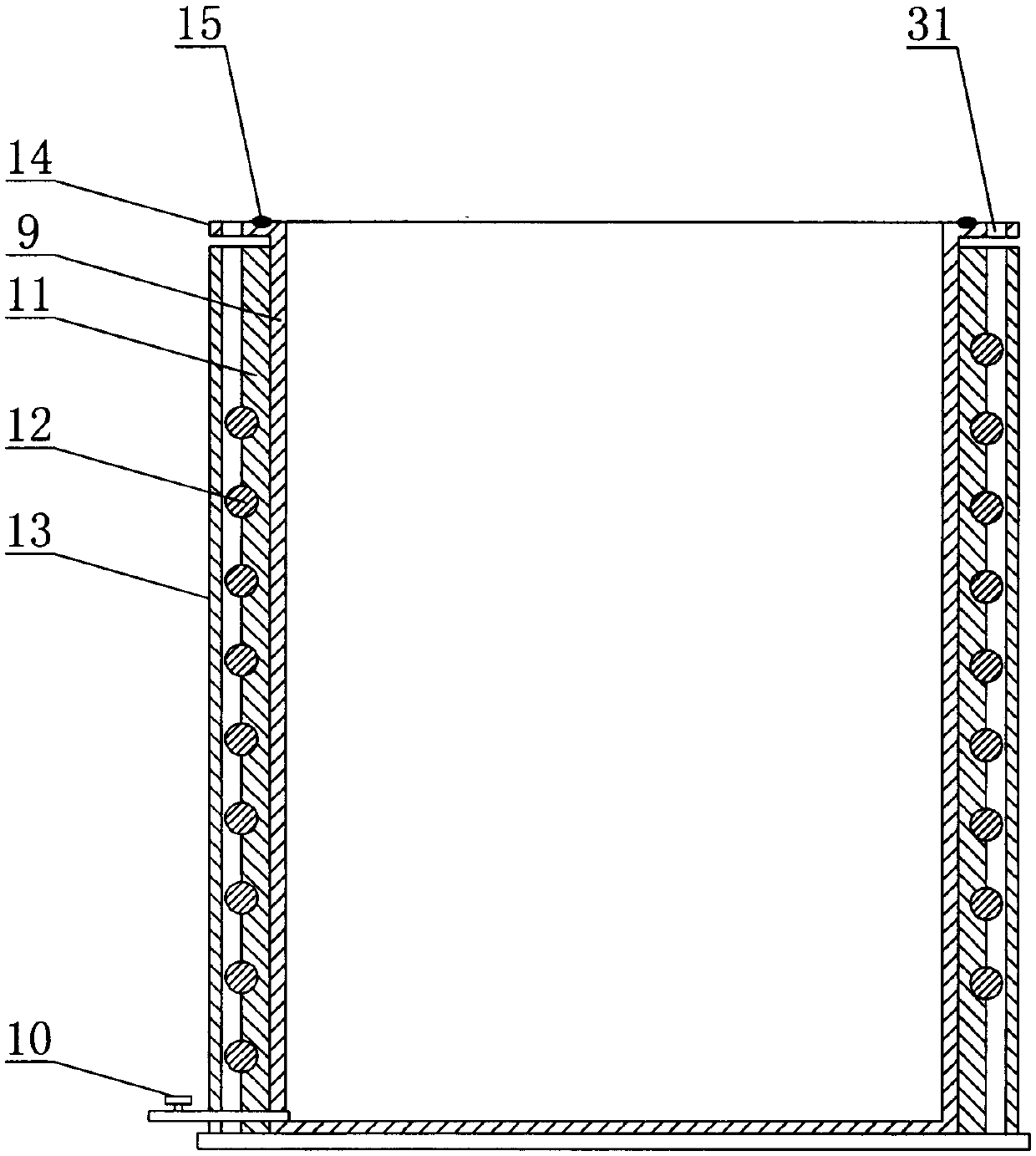

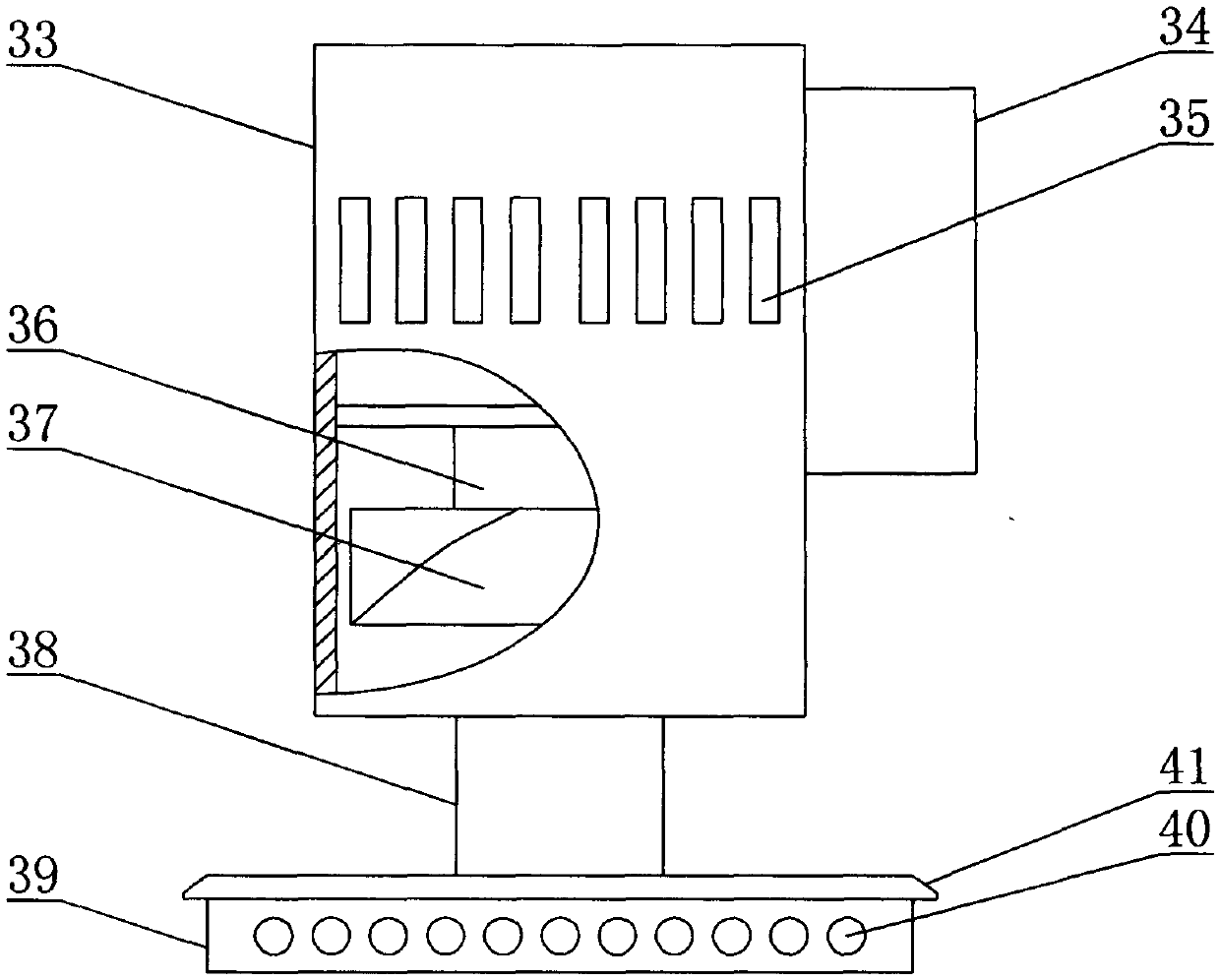

[0034] Embodiment: The present invention is a chemical material mixing device, which includes a frame, and the frame is welded by square pipes. Universal wheels are installed on the bottom of the frame, which can facilitate the movement of the present invention. The lower part of the frame is provided with a first guide rail horizontally, the first guide rail adopts a linear guide rail, and the first guide rail is connected with the frame through hexagon socket bolts. A first sliding block is arranged on the first guide rail, a first nut is arranged on the first sliding block, and the first nut is connected with the first sliding block through a bolt. A first lead screw is arranged in the first screw nut, and a first lead screw fixing seat is arranged at both ends of the first lead screw. The screw fixing seat provides support for the first lead screw. One end of the first lead screw is provided with a first step motor, the first step motor is connected to the first lead scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com