Deduster box

A dust collector and box technology, applied in the field of machinery, can solve the problems of reducing the working efficiency of the dust collector and the cleaning cycle is not long, and achieve the effects of stable structure, prolonging the cleaning cycle, and uniform gas volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

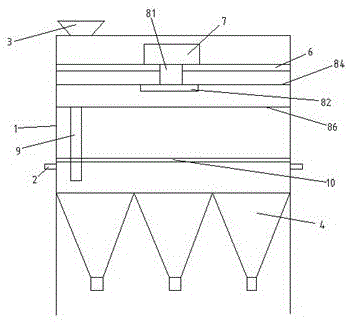

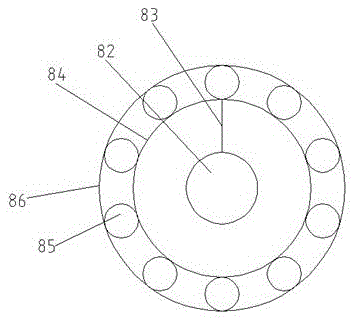

[0015] refer to Figure 1 to Figure 2 The embodiment of a dust collector box of the present invention will be further described.

[0016] A dust collector box body, including a box body 1, an air inlet 2, an air outlet 3, and an ash hopper 4, the bottom of the box body 1 is connected to the ash hopper 4, and it is characterized in that the side wall of the box body 1 is connected to the air inlet 2. The top of the chassis body 1 is connected to the air outlet 3, and the interior of the chassis body 1 is provided with a shock absorbing plate 6. The setting of the shock absorbing plate 6 plays a role of shock absorption and reduces the influence of the motor on the dust collector. An explosion-proof motor 7 is arranged above the damping plate 6. The setting of the explosion-proof motor 7 is to prevent the motor from sparking and improve the safety performance of the equipment. The bottom of the explosion-proof motor 7 is connected to a rotating shaft 81, and the rotating shaft 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com