Grass discharge and anti-blocking device for harvester and its working method

A harvester and grass-arranging technology, which is applied to harvesters, cutters, agricultural machinery and implements, etc., can solve problems such as hindering the development of inspection work, high labor intensity of cleaning work, affecting the normal work of machinery, etc., and achieves strong adaptability. , Improve the effect of weeding, easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing of description and specific embodiment:

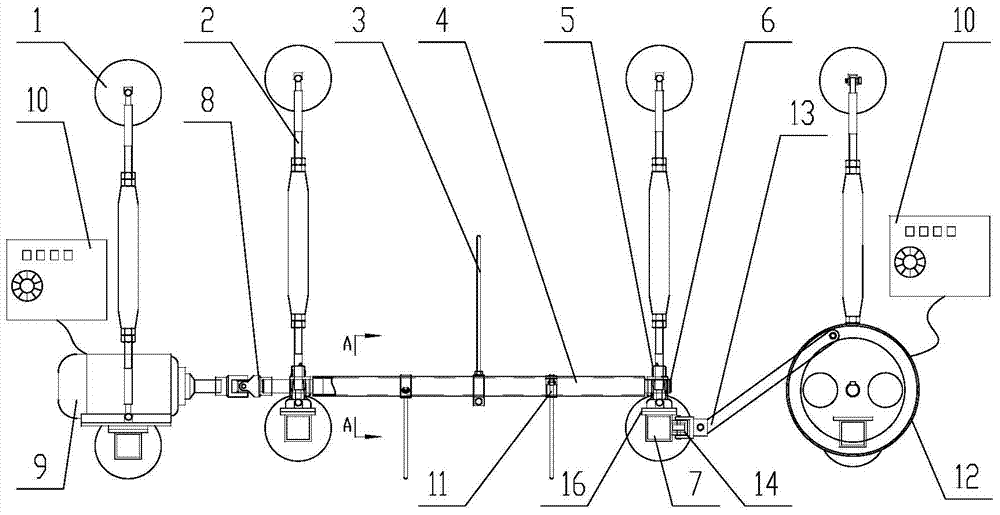

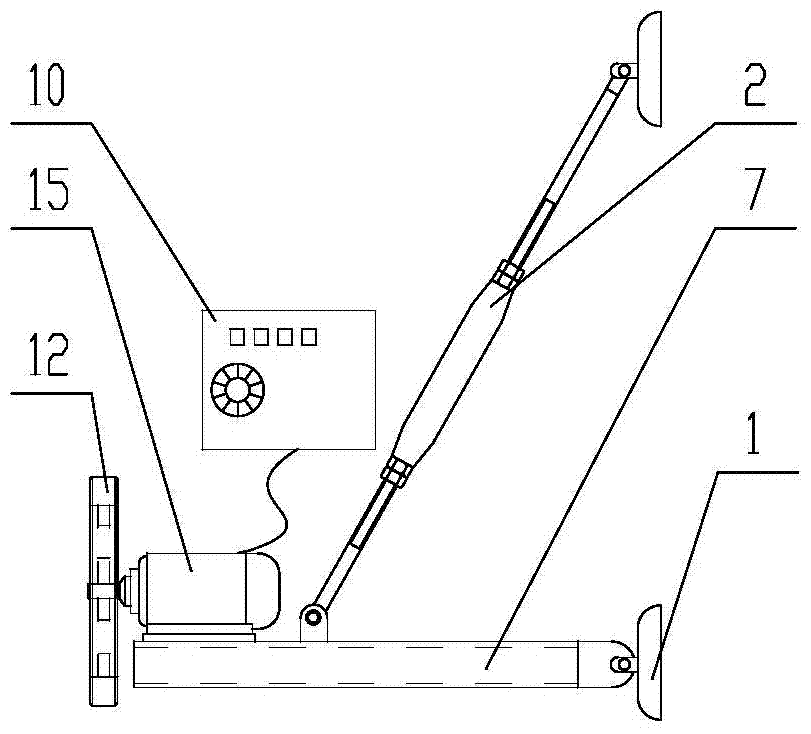

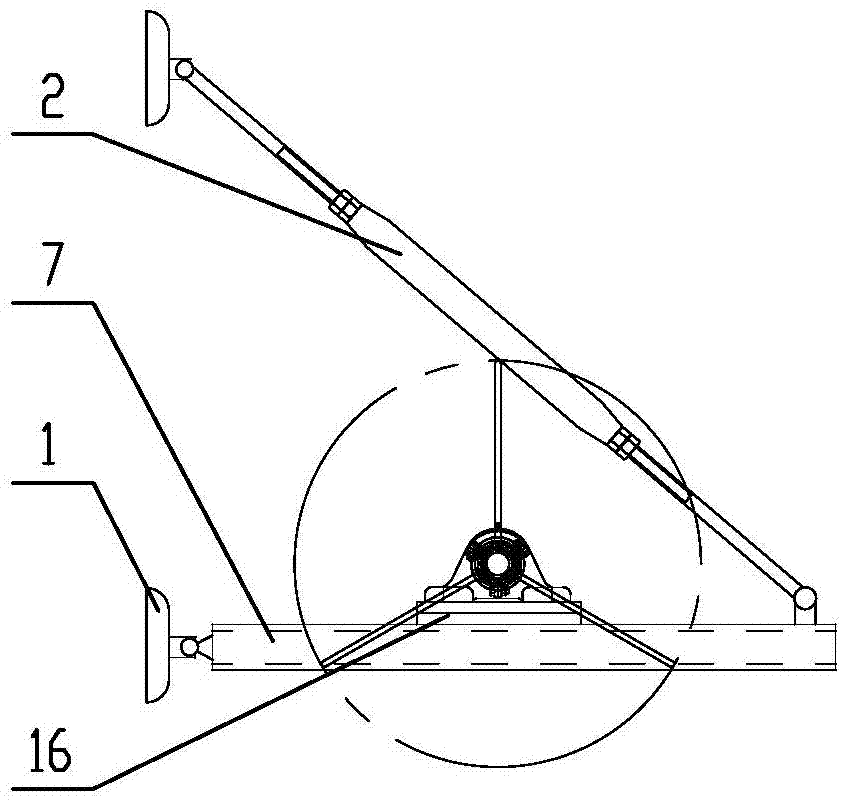

[0030] Such as figure 1 As shown, the harvester grass discharge and anti-blocking device includes a transmission tube shaft 4, and three shifting teeth 3 are installed on the transmission tube shaft 4, and the shifting teeth 3 are distributed in a spiral shape along the axial direction of the transmission tube shaft 4, as image 3 As shown, the three shifting teeth 3 circle around the transmission tube shaft 4, and the angle between them is 60°, forming a uniform distribution in the circumferential direction of the transmission tube shaft 4, while the transmission tube shaft 4 rotates on its axis The direction is reciprocating, and the transmission tube shaft 4 drives the shifting gear 3 to move, and the transmission tube shaft 4 is provided with a connecting device connected with the harvester.

[0031] The shifting tooth 3 is rod-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com