A control method for preventing pitch motor overtemperature in wind turbines

A technology for wind turbines and pitch motors, which is applied in the control of wind turbines, motor control, wind turbines, etc., can solve the problems of complex realization process, inconvenient actual operation, high cost, simple operation, prevention of over-temperature conditions, and high cost. Precisely tuned effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

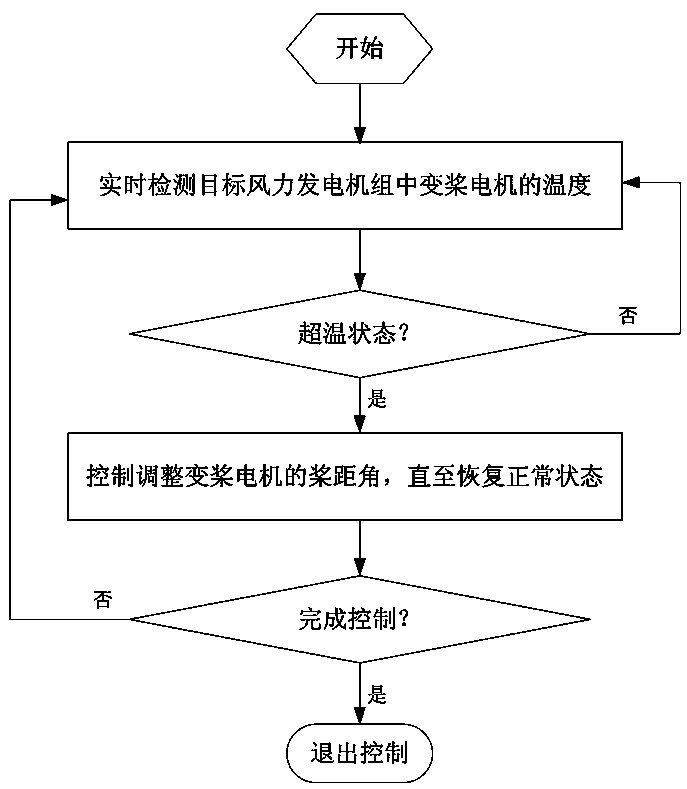

[0032] Such as figure 1 As shown, this embodiment is used in a control method for preventing pitch motor overheating in a wind power generating set, and the steps include:

[0033] 1) Real-time detection of the temperature of the pitch motor in the target wind turbine, if the detected temperature reaches the over-temperature state, go to step 2);

[0034] 2) Control and adjust the pitch angle of the pitch motor to reduce the temperature of the pitch motor to a normal state, return to step 1) until exiting the control.

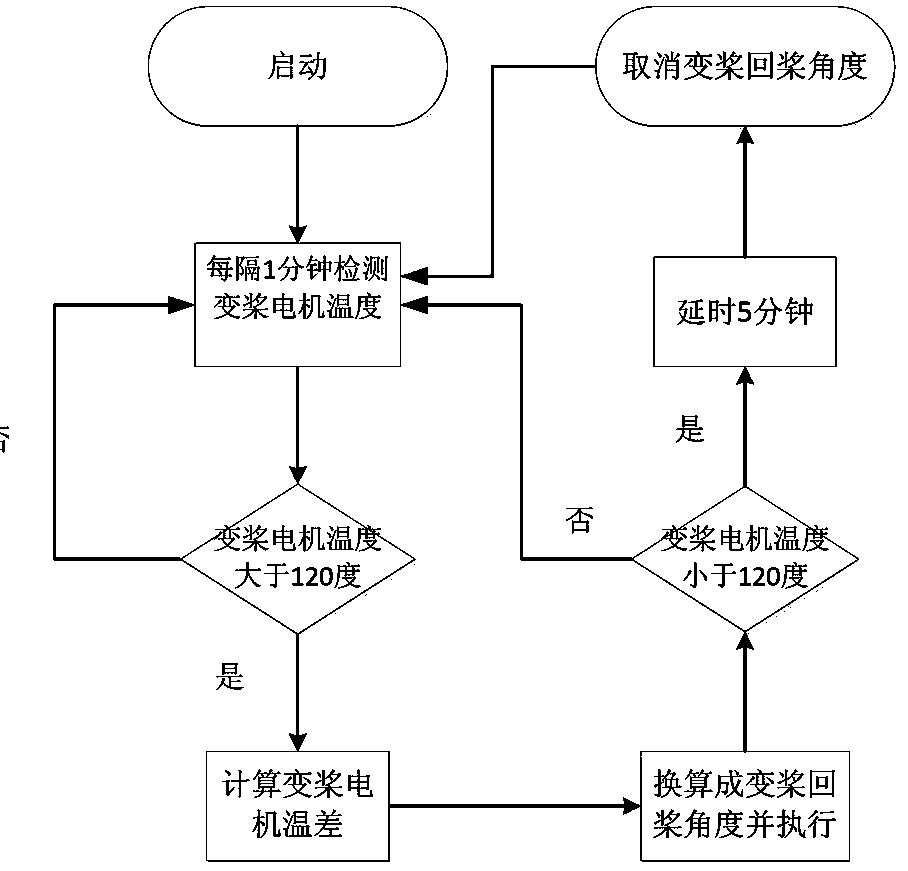

[0035] In this embodiment, the factors related to the temperature of the pitch motor are determined and obtained by testing different wind power generators in different wind farms in advance. As shown in Table 1, when testing a wind turbine in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com