Novel dust sealing external pressure type expansion joint

An external pressure, expansion joint technology, applied in pipeline expansion compensation devices, pipes/pipe joints/pipe fittings, mechanical equipment, etc. problems, to achieve the effect of improving service life, reducing matching corrosion, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

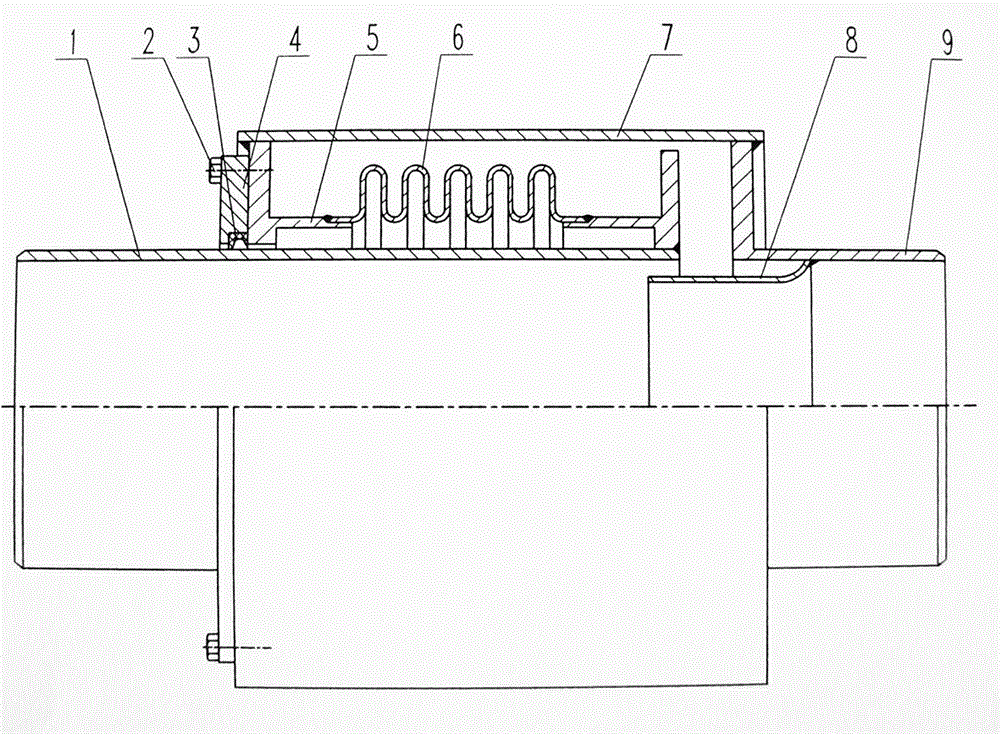

[0013] A new type of dust-sealed external pressure expansion joint shown in the accompanying drawing, which includes long connecting pipe 1, bolt 2, packing 3, gland 4, joint 5, bellows 6, shell 7, inner protective pipe 8 and short connecting pipe 9 . The inner hole of the short connecting pipe 9 located at the right end is fixedly connected with the trumpet-shaped inner protective pipe 8 to form a diversion structure, and the short connecting pipe 9 is sealed and connected with the right port of the cylindrical shell 7 by a flange to form a whole. The two ends of the bellows 6 of the elastic element are respectively fixedly connected with the joint 5 facing the outside of the flange, and the long connecting pipe 1 is inserted into the hole and fixedly connected with the inner hole of the joint 5 at the right end to form an axial compensation structure. Insert it into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com