Progressive-strength concrete wall section dirt band limit receding gob-side entry retaining method

A technology for concrete and entry retention, which is applied in earthwork drilling, shaft equipment, wellbore lining, etc. It can solve problems such as unformed specifications, avoid damage or destruction, reduce costs, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

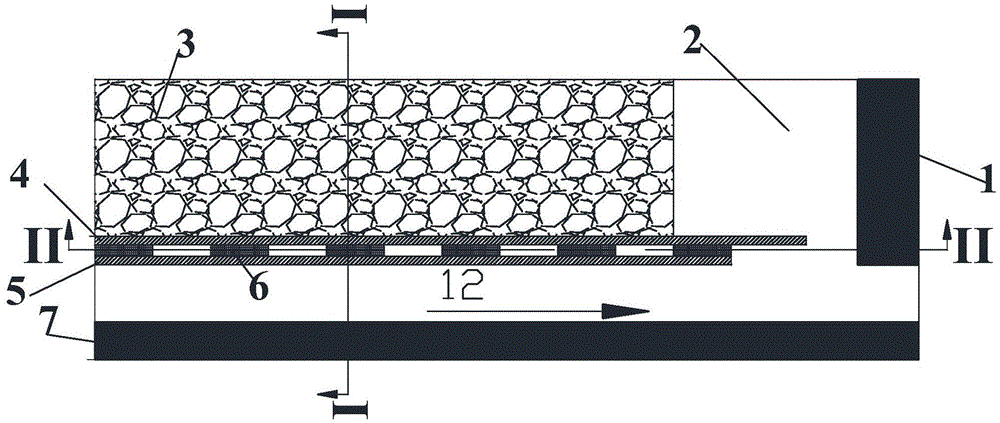

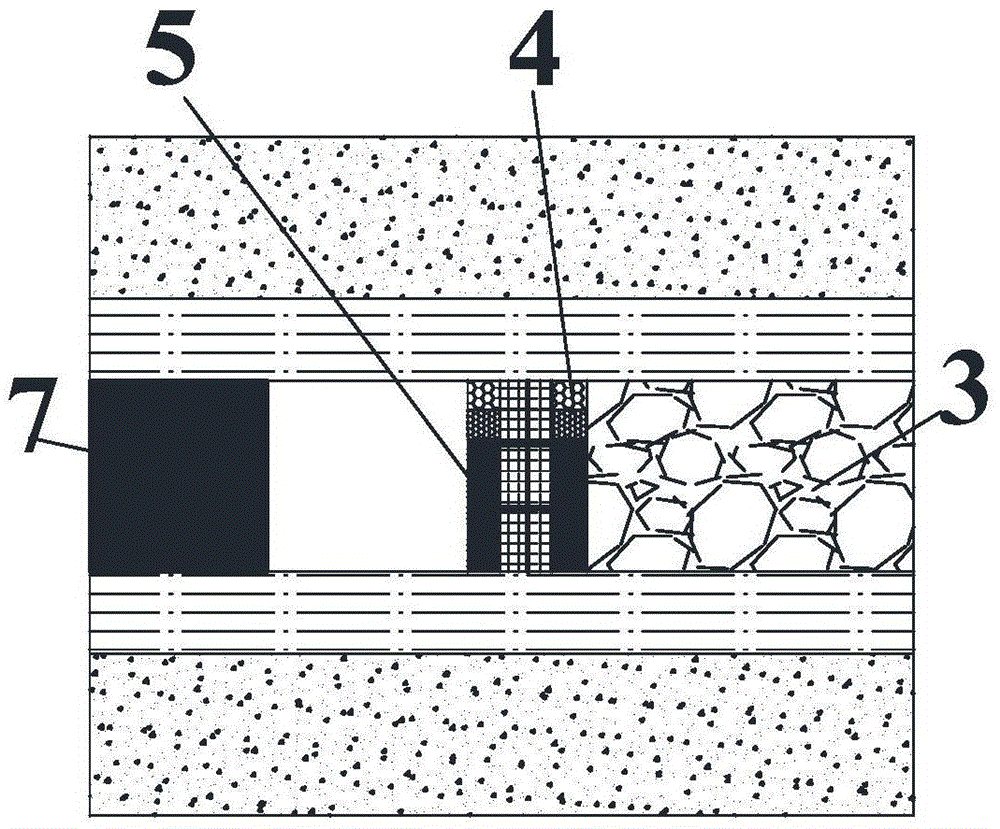

[0057] Take the transportation lane reserved in the upper section of a coal mine as the return airway in the lower section as an example. The height of the roadway is 3.0m, the roof collapse step of the working face is 15m, the coal seam is a stable rock formation, and the allowable sinking of the roof is 1.0m ; The ultimate compressive strength of the support is designed to be 25MPa, and the width is 1.8m; a certain number of metal yielding anchors are evenly installed on the roof and side walls of the roadway.

[0058] When carrying out gob-side entry retention for this roadway, the specific steps are as follows:

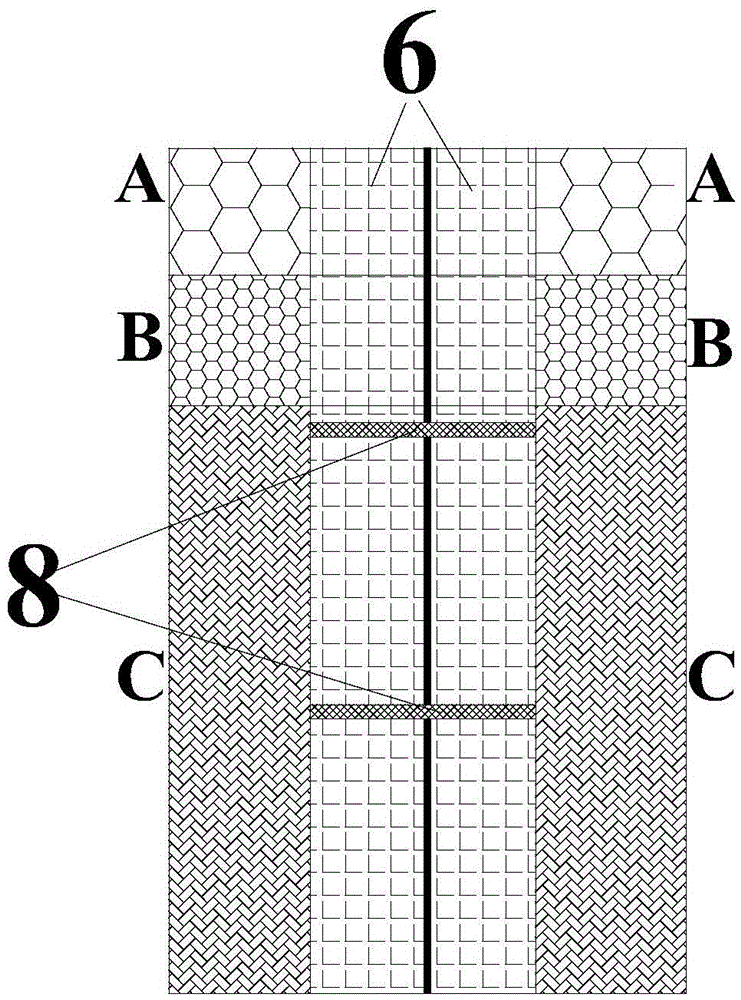

[0059] (1) The support resistance of the pressure body is calculated to be about 15MPa, then the rated pressures of the two upper sections of the inner wall are "A = 15MPa, B = 17MPa", and the height values of the three sections are A = 0.6m, B = 0.6 m, C=1.3m, in which the compressible height of each part of the design is 0.5, 0.3m, to ensure the initial slow s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com