Indoor lifting wall spliced based on 3D module

A lifting type, wall technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of easy pollution, time-consuming, etc., and achieve the effects of good stability, easy operation, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

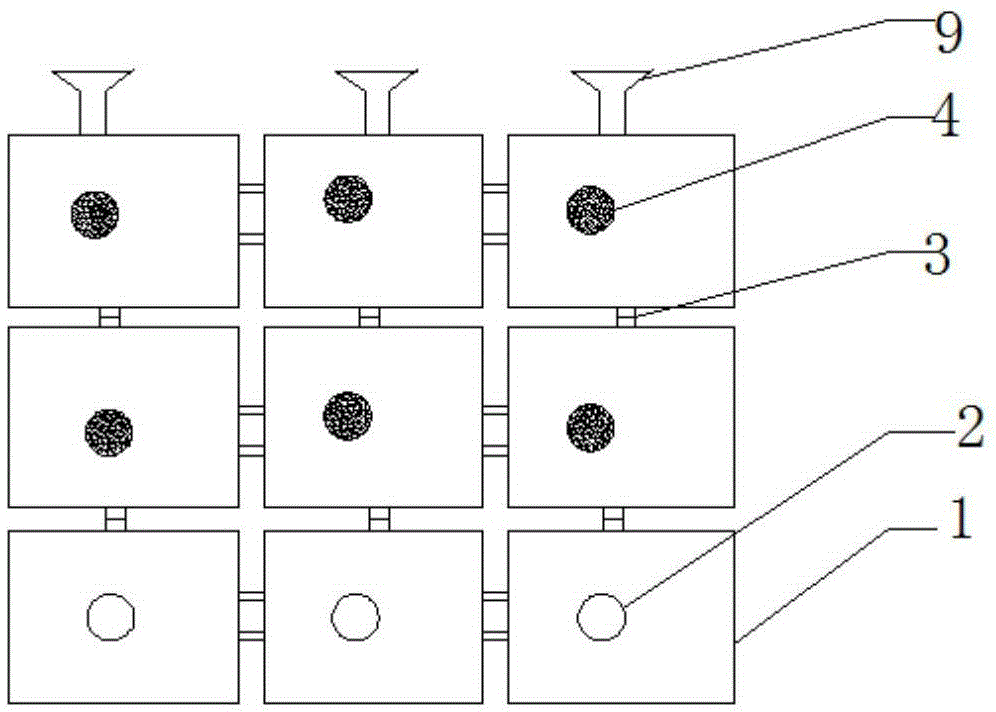

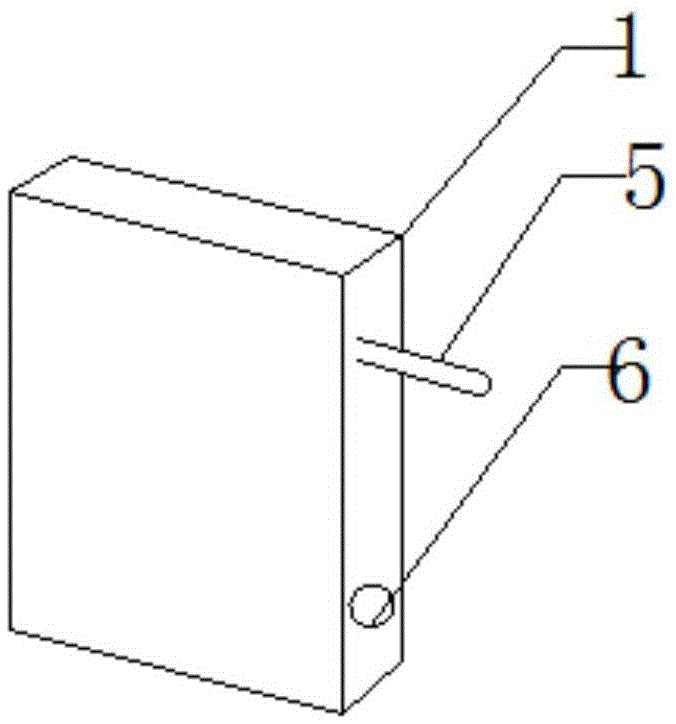

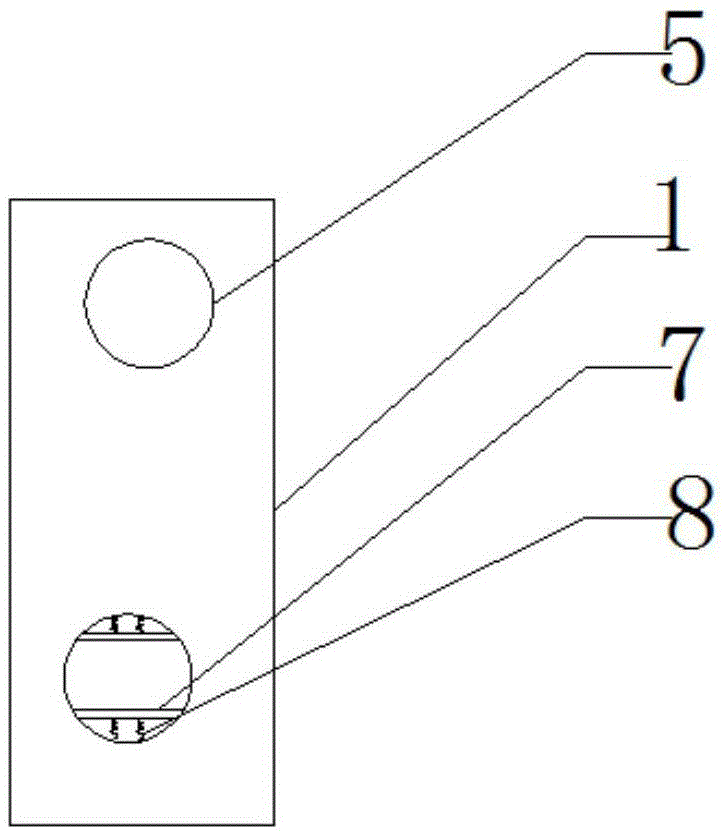

[0017] Specific implementation method: When using, it is necessary to check whether the hinge 3 can be used normally, whether the sub-wall body 1 is damaged, whether the locking plate 7 can be used normally, if the inspection is defective, it cannot be used, and if everything is normal, it can be carried out. In use, bring the nine sub-walls 1 to the construction site for splicing, insert the connecting columns 5 on the left and right end faces of the sub-walls into the fixing cavity 6, and use the spring 8 to squeeze the locking plate 7 tightly The connecting column 5 ensures that the connecting column 5 will not fall off, and the nine sub-walls 1 are spliced into three rows, and the three rows of sub-walls 1 are connected together up and down sequentially by using bolts and hinges 3, wherein the sub-walls 1 with suction cups 9 are installed Put it on the top, and use the suction cup to fix the wall on the beam after the wall is spliced. The permanent magnet 2 and the iron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com