Plate-type ballast bed turnover device

A technology of turning device and slab track bed, which is applied in the direction of transportation and packaging, traveling bridge cranes, load hanging components, etc. It can solve the problems of inability to turn over objects and meet the requirements of slab turnover, and achieve the requirements of reducing conditions, The effect of improving work safety efficiency and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

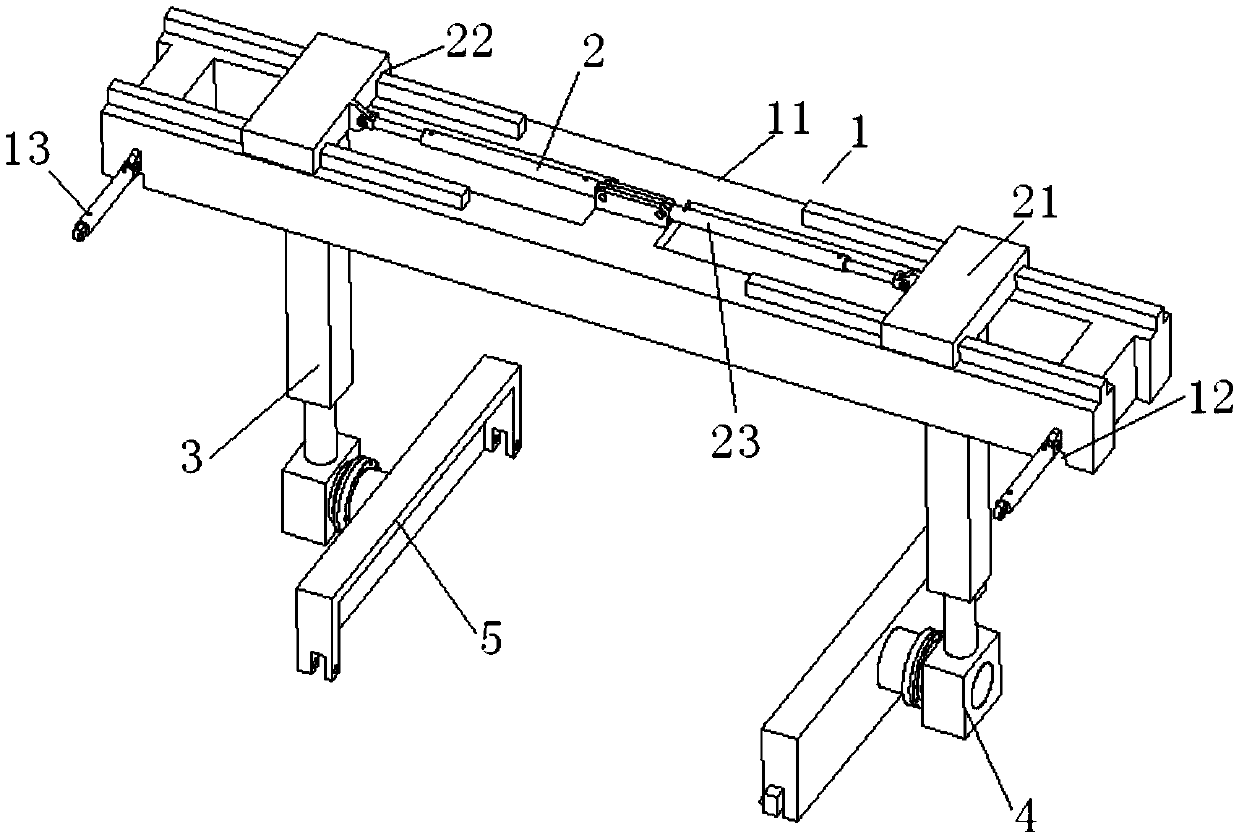

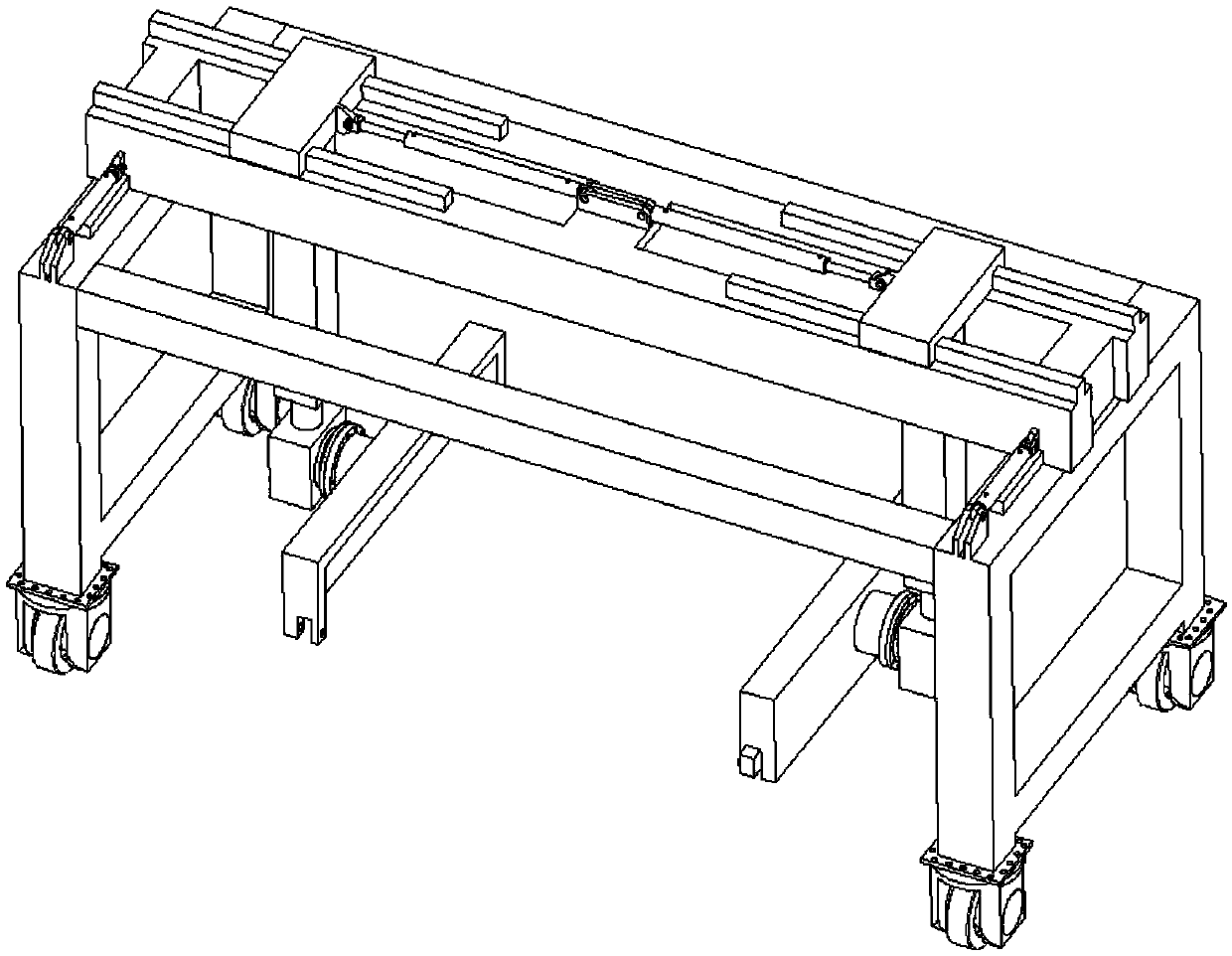

[0023] see figure 1 with 2 , shows the slab ballast bed turning device of the present invention.

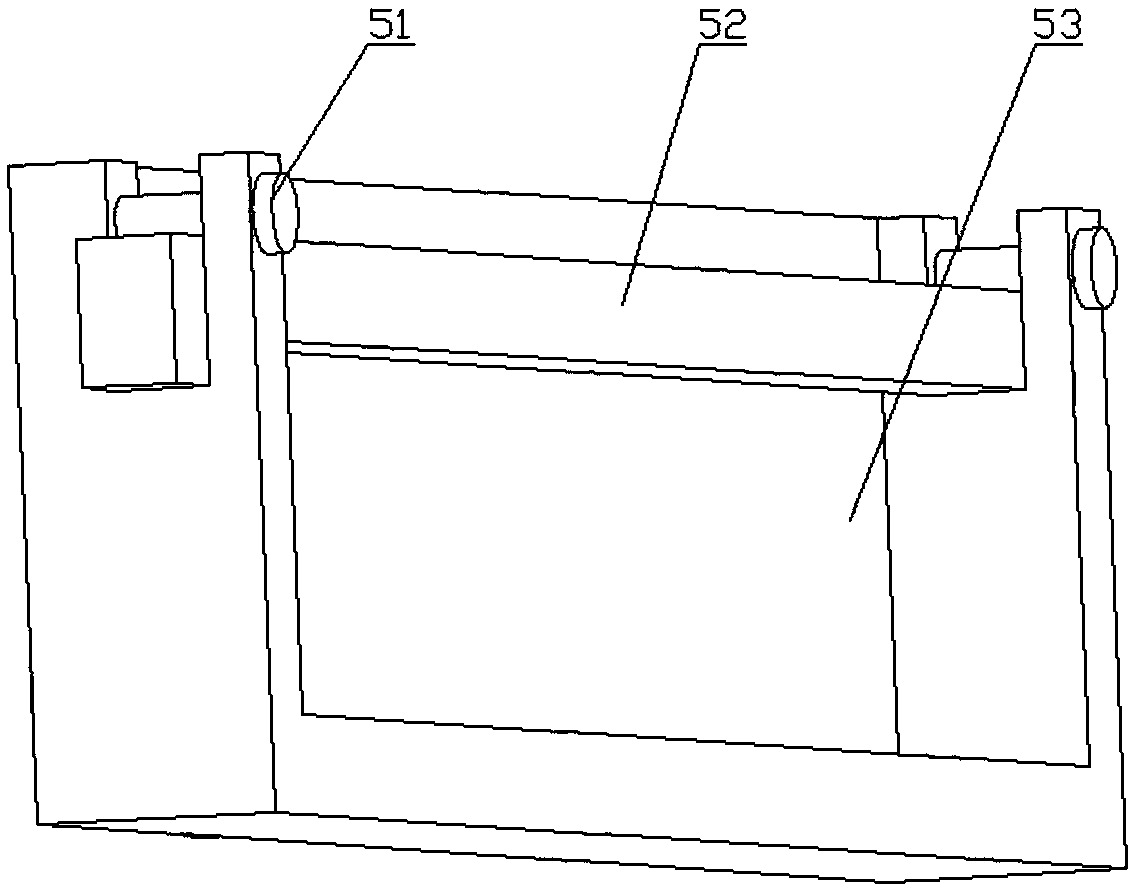

[0024] The slab track bed turning device includes a longitudinal movement mechanism 1, a transverse movement mechanism 2, a vertical lifting mechanism 3, a turning mechanism 4 and a special fixture 5, and the longitudinal movement mechanism 1 and the transverse movement mechanism are connected with a chute through a slideway, The lateral moving mechanism 2 is connected with the vertical lifting mechanism 3 through a slideway and the chute, the turning mechanism 4 is connected with the vertical lifting mechanism 3 through a rotating mechanism, and the special clamp 5 is fixed on one end of the turning mechanism 4 . The whole device is installed on the main beam structure of the lifting equipment.

[0025] Wherein, the longitudinal movement mechanism 1 is composed of a longitudinal movement girder 11, a slideway 12 and a longitudinal driving member 13. The longitudinal movement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com