Method for carrying out pile leg connection by utilizing 3000t floating crane

A technology of pile legs and floating cranes, which is applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of increased cost and operational risk, segmental closure of pile legs, etc., to shorten the construction period, reduce the period of closure, Guaranteeing the effect of build quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to deepen the understanding of the present invention, the present invention will be described in further detail below. This embodiment is only used to explain the present invention, and does not constitute a limitation on the protection scope of the present invention.

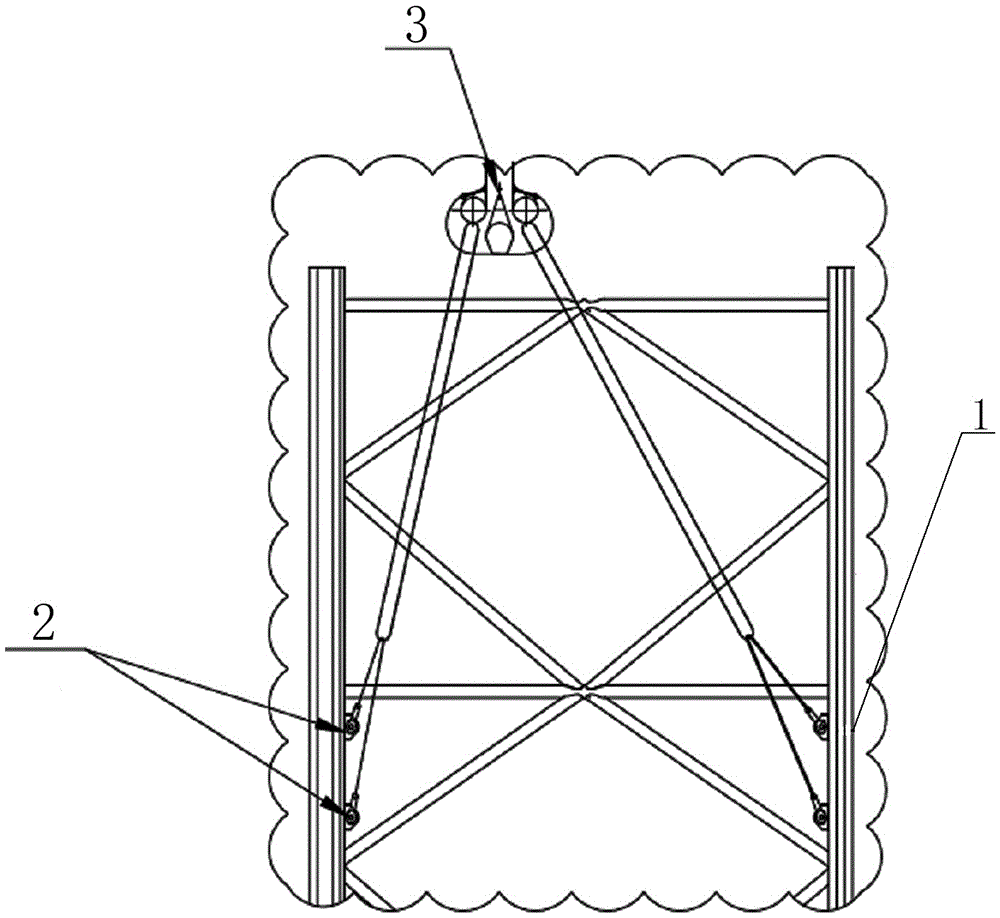

[0023] A method of using a 3000t floating crane to connect a pile leg of the present invention, such as figure 1 As shown in the figure, 6 special 100t lifting lugs 2 are welded on the top of the upper section of the total leg section 1 in advance, and the distance from the top is about 10m, which is reserved for the adjustment of the height of the floating hook 3 when positioning the pile. margin.

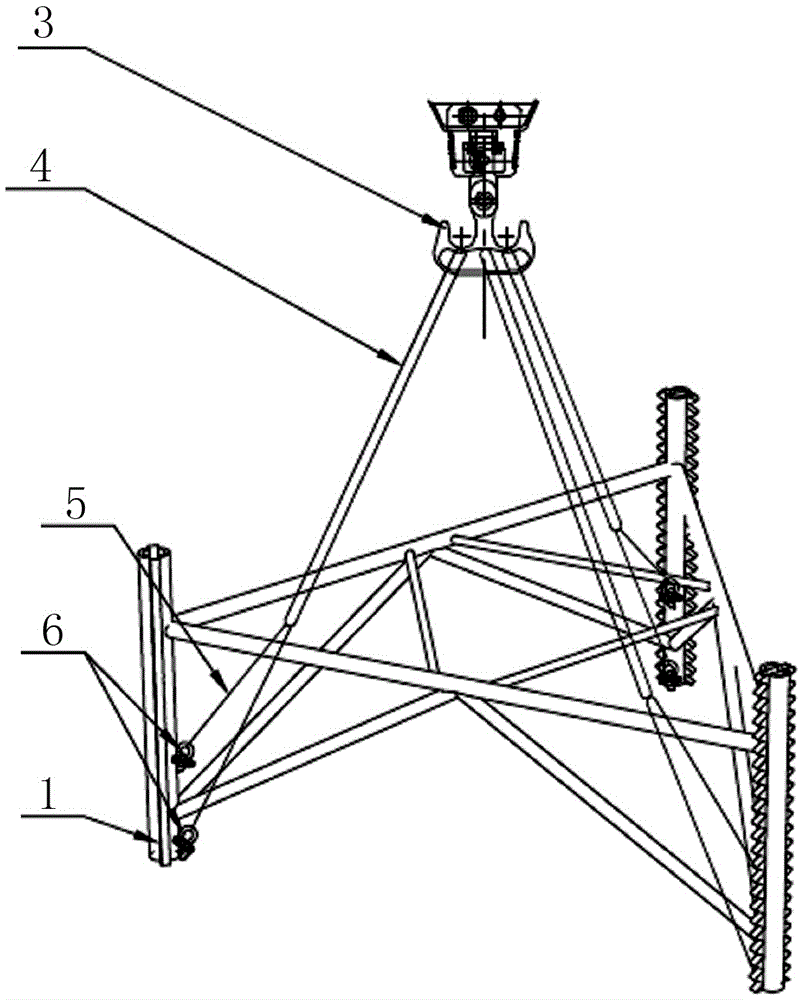

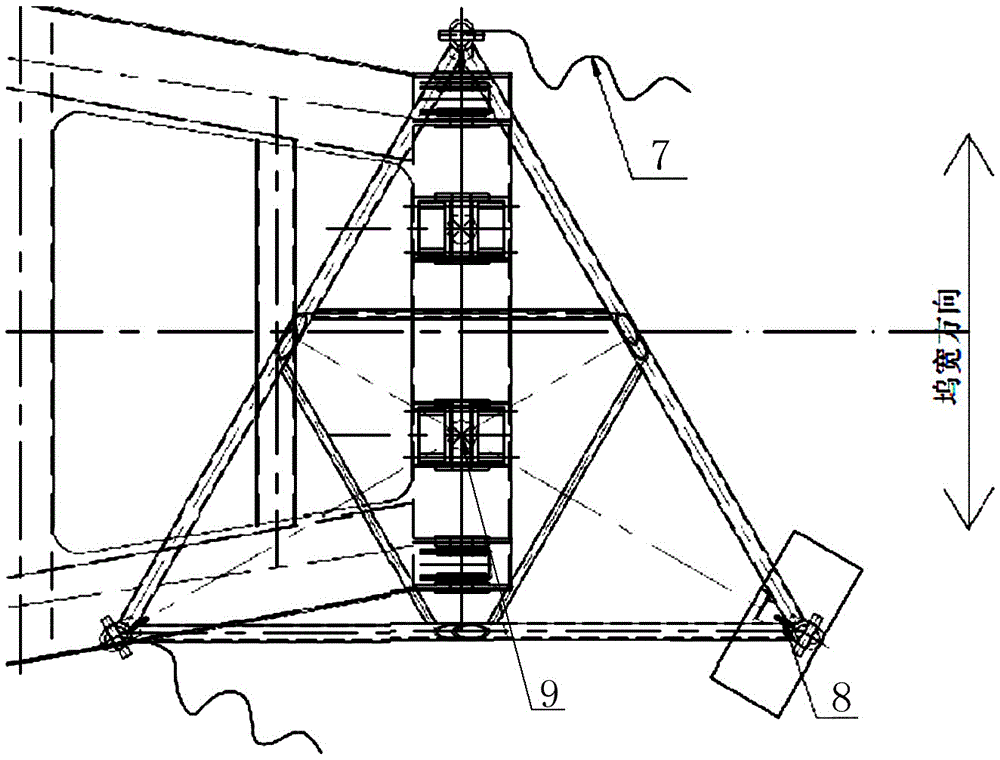

[0024] like figure 2 As shown, prepare these slings in advance before lifting the total leg section 1: 200t Dyneema high-strength annular sling 4, a single length of 10m, a total of 3; 100t Dyneema high-strength annular sling 5, a single length 6m, a total of 3; 110t high-strength wide-body shack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com