A production line for canned and capped tablets

A production line and canning technology, applied in packaging, packaging protection, packaging sterilization, etc., can solve the problems of inaccurate feeding of medicine bottles, high failure rate of capacity, high procurement cost, etc., and achieve simple structure and high pass rate , the effect of a high level of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

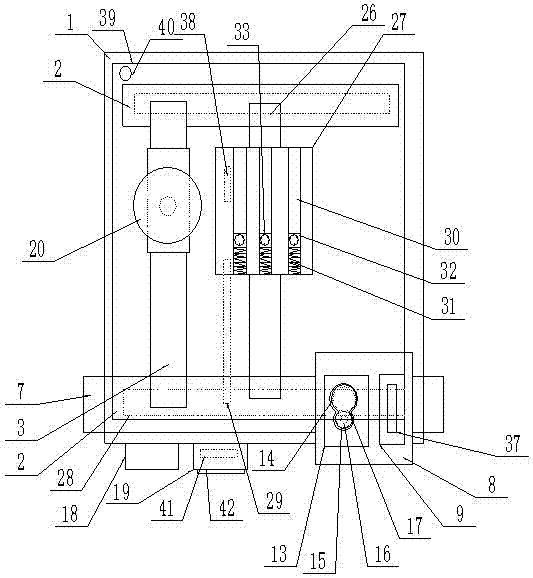

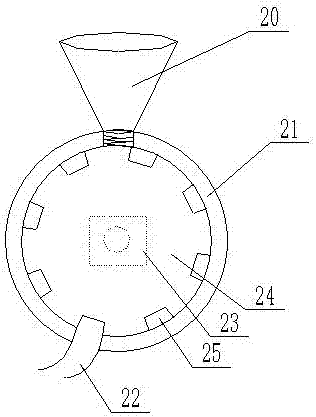

[0020] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, a tablet canning and capping production line includes a workbench 1 and a pair of gantry frames 2 arranged on the workbench 1. The inside of one of the gantry frames 2 is a cavity structure, and the pair of gantry frames 2 is provided with a horizontal plate 3, the horizontal plate 3 is provided with a counting and dispensing unit, the workbench 1 is provided with a conveying unit, and the cavity structure of one of the gantry 2 is provided with a die unit, so The die unit is composed of a film roll 4 arranged in a leg of the gantry 2, an auxiliary rotating shaft 5 and an active pinch roller 6, an opening arranged on the upper surface of the gantry 2 crossbeam, and an opening arranged on the gantry 2 crossbeam. The guide frame 7, the air valve box 8 that is arranged on the guide frame 7 and can move along the length direction of the guide frame 7, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com