A docking pier and cloth pier method in the bow and stern area

A regional and dock pier technology, applied in dry docks, ships, slipways, etc., can solve the problems of difficult to achieve continuous arrangement of piers, the force of dock piers exceeds the allowable range, and the adjustment of unfavorable levels, so as to improve the bearing area and continuous performance, increase the bearing area, and improve the effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

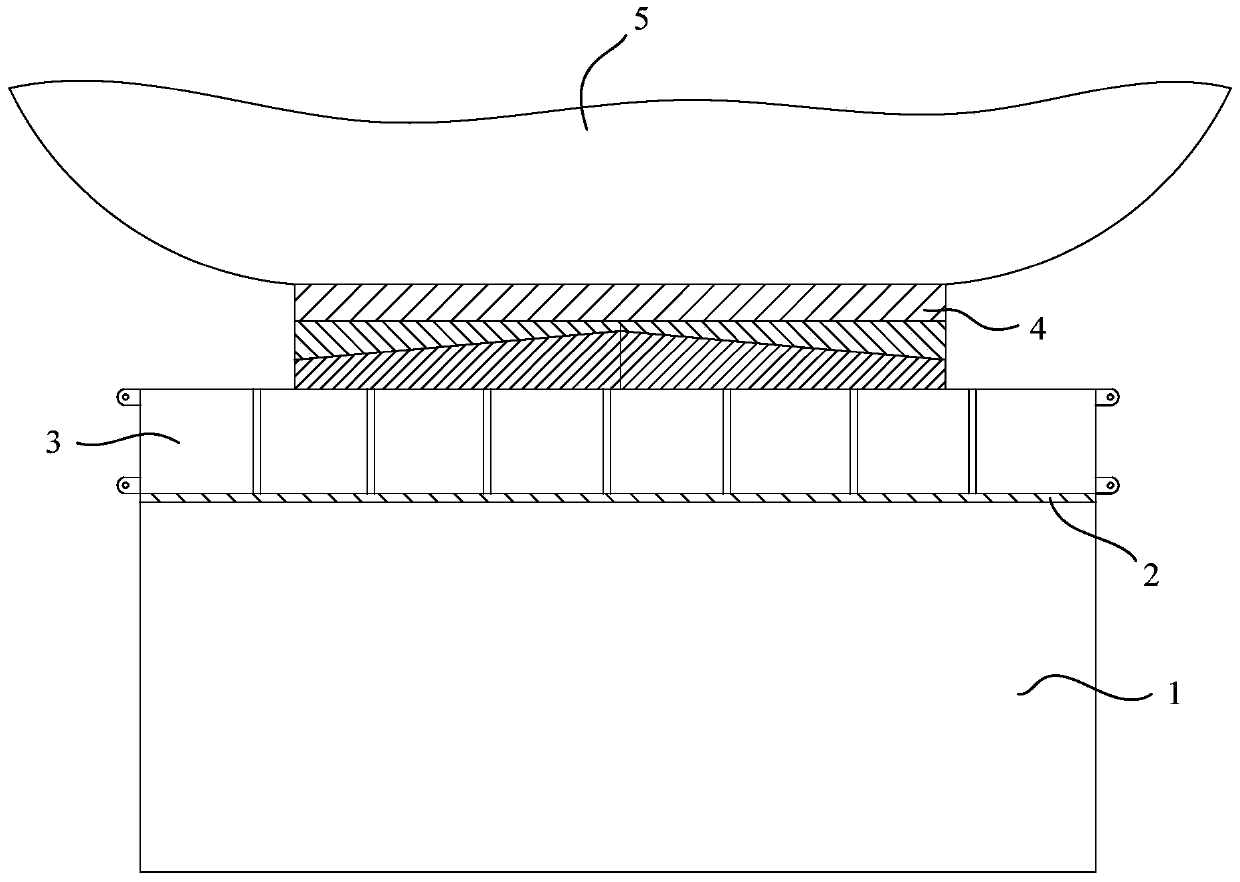

[0028] Such as figure 1 As shown, a docking pier in the bow and stern area, from bottom to top, is the pier body 1, the height adjustment plate 2, the pressure steel beam 3 and the pier wood 4, the cross-section of the pier body 1 and the pressure steel beam 3 The shape and size are the same, which can avoid the structure of the existing dock pier body 1 being narrow at the top and wide at the bottom, and can realize the continuous arrangement of the pier body 1 in the bow and stern areas, and increase the bearing area.

[0029] The height adjustment plate 2 is arranged between the pier body 1 and the pressure-bearing steel beam 3, so that the upper surface of the pressure-bearing steel beam 3 remains horizontal, which can avoid that the upper surface of the dock pier cannot be kept horizontal when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com