Electrofusion bending pipe fittings and its post-firing process

A technology for pipe bending and wire routing, which is applied in the direction of pipe connection layout, pipe/pipe joint/pipe fittings, mechanical equipment, etc. It can solve the problems of electric heating wire fusing, failure to realize pipe fitting welding, etc., and achieve the effect of reducing the probability of being blown.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

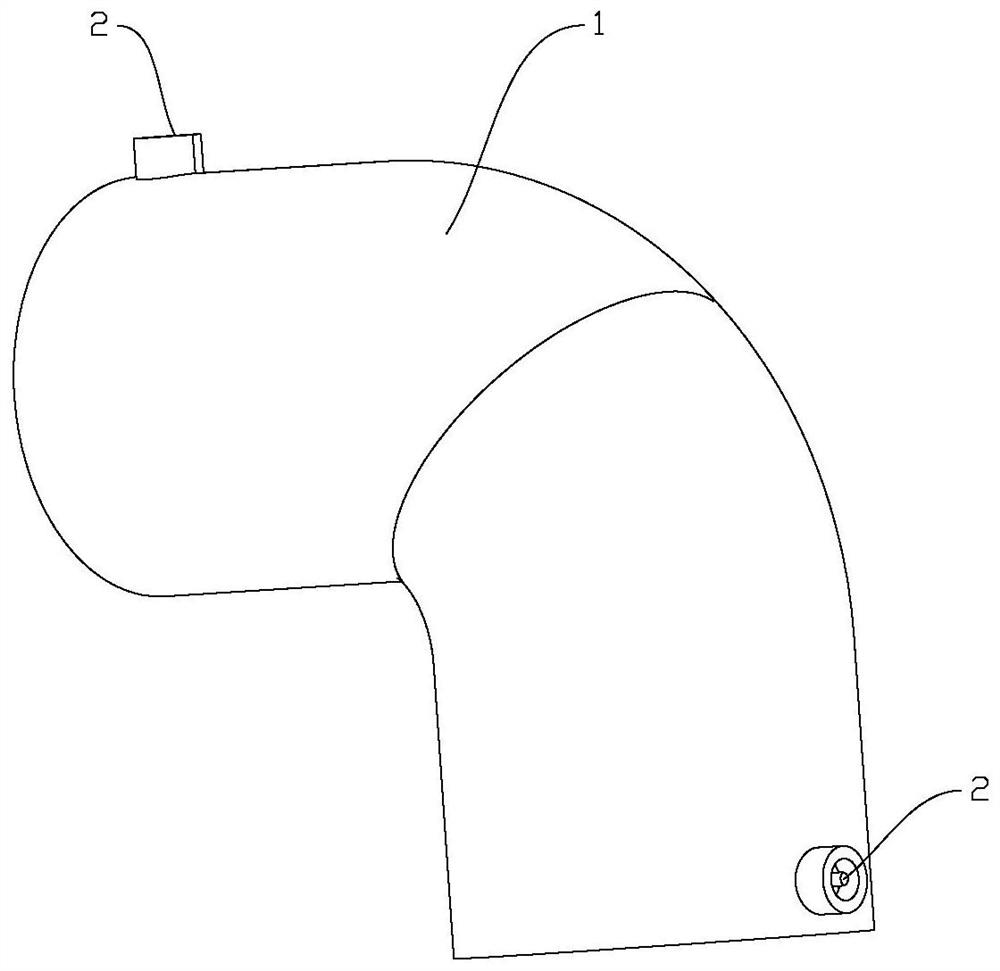

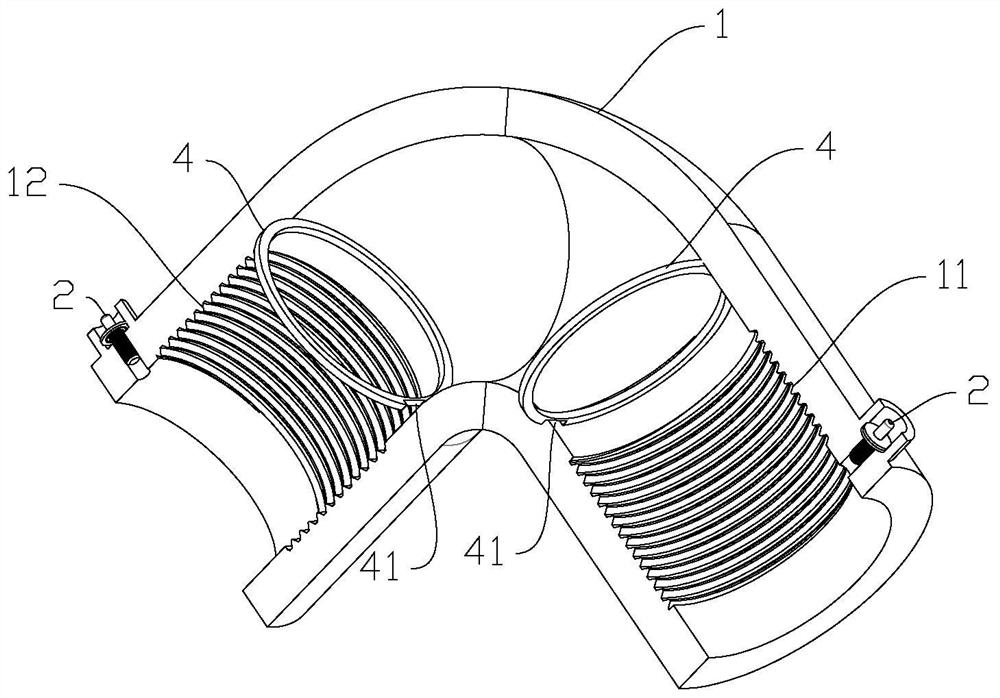

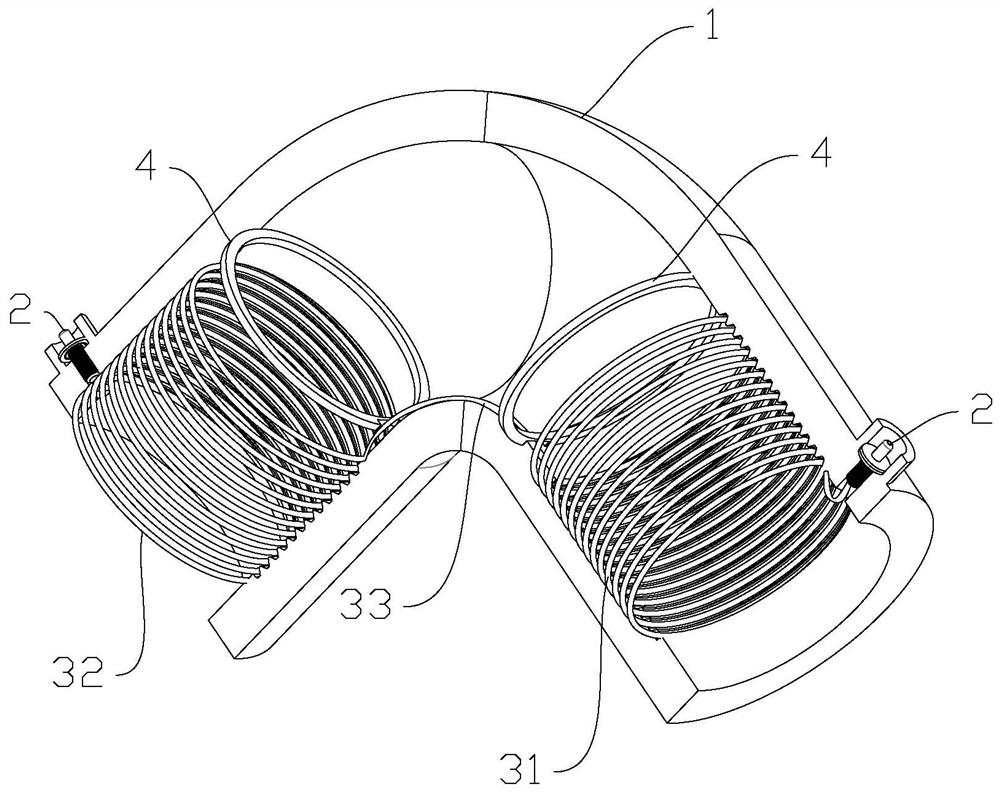

[0028] Electrofusion bending pipe fitting 1, first refer to the attached figure 1 , is the overall appearance diagram of the electrofusion pipe bend 1, wherein the two ends of the bend pipe 1 are respectively provided with conductive terminals 2, continue to refer to the attached figure 2 and 3 , the first wire slot 11 and the second wire slot 12 are respectively provided at both ends of the elbow piece 1 for embedding the first heating wire loop 31 and the second heating wire loop 32, and the two ends of the elbow piece 1 are close to the bend Valve cavity gear rings 4 are provided at all places, and a relief groove 41 is provided between the valve cavity gear ring 4 and the pipe wall to facilitate the passage of the bridging heating wire 33 connecting the first wire groove 11 and the second wire groove 12, and The first heating wire, the bridging heating wire 33 and the second heating wire are all arranged through a continuous heating wire, and here the relief groove 41 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com