Boring tool holder of combined machining machine special for drum shafts

A composite processing and reel shaft technology, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of time-consuming and laborious processing accuracy, difficult to control, etc., and achieve high processing efficiency, good shock resistance, and reliability. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

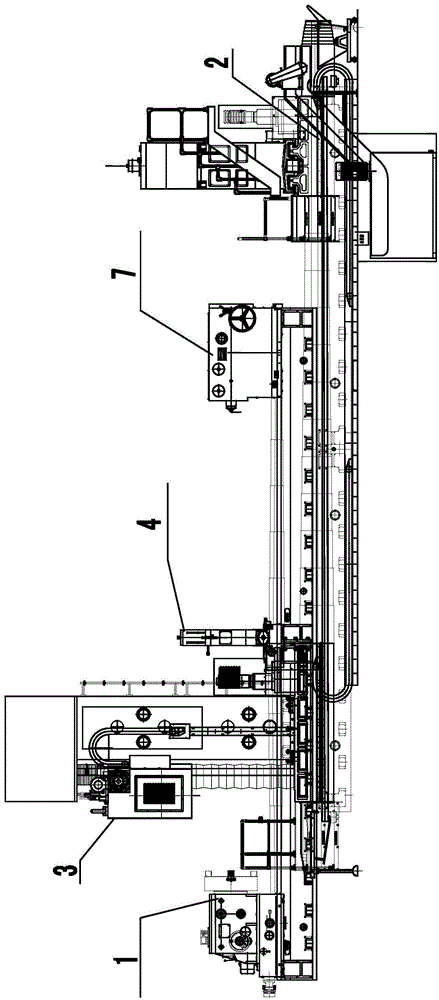

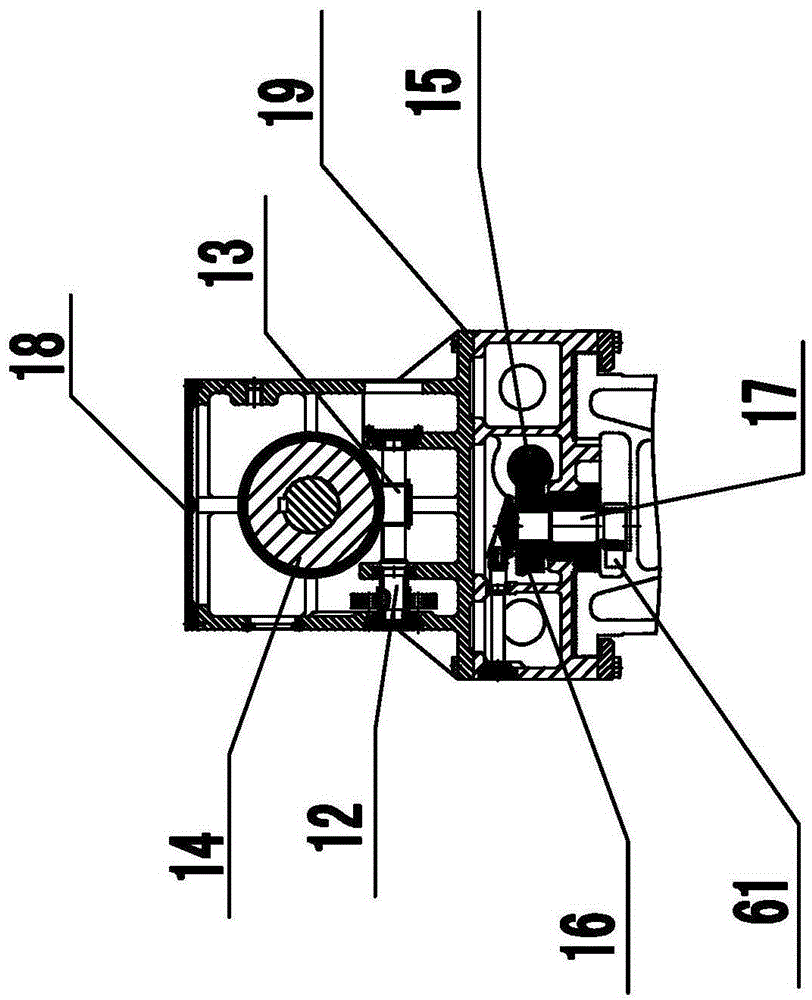

[0029] As shown in the figure, the boring tool holder disclosed by the present invention is installed on the special machine for compound processing of mandrel shaft. Boring tool rest 2, milling cutter rest 3, support center frame 4, workpiece bed 5, tool rest bed 6, described workpiece bed 5 is arranged between two described tool rest beds 6, and described tool rest A boring tool holder 2 and a milling tool holder 3 are respectively arranged at both ends of the bed 6, and the boring tool holder 2 or the milling tool holder 3 can move along the tool holder bed 6; the indexing headstock 1, supporting The center frame 4 and the top tight tailstock 7 are sequentially arranged on the workpiece bed 5, and the indexing spindle box 1 and the support center frame 4 can move along the workpiece bed 5; the above moving methods are all controlled by a dou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com