Piston gravity casting machine

A gravity casting machine and piston technology, which is used in casting equipment, manufacturing tools, equipment for feeding molten metal into casting molds, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

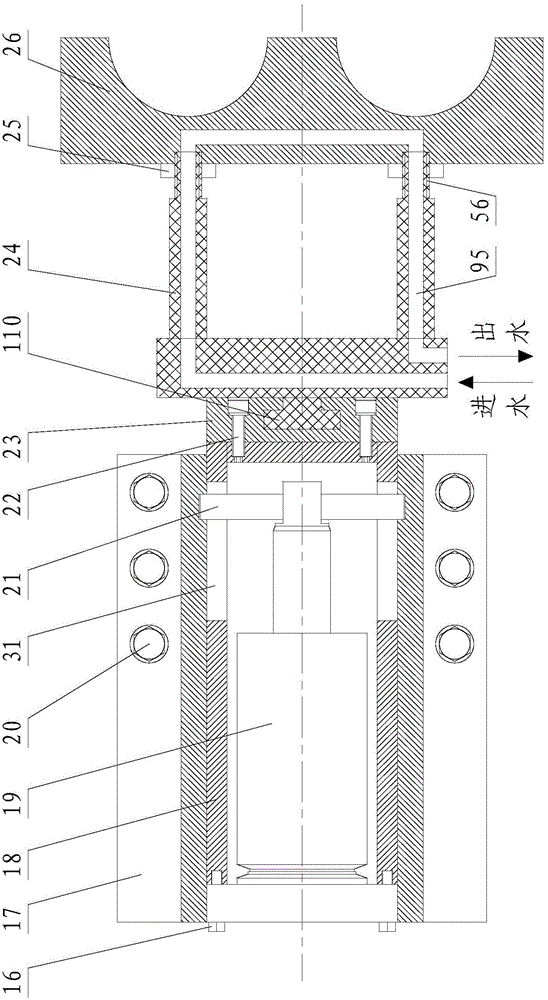

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

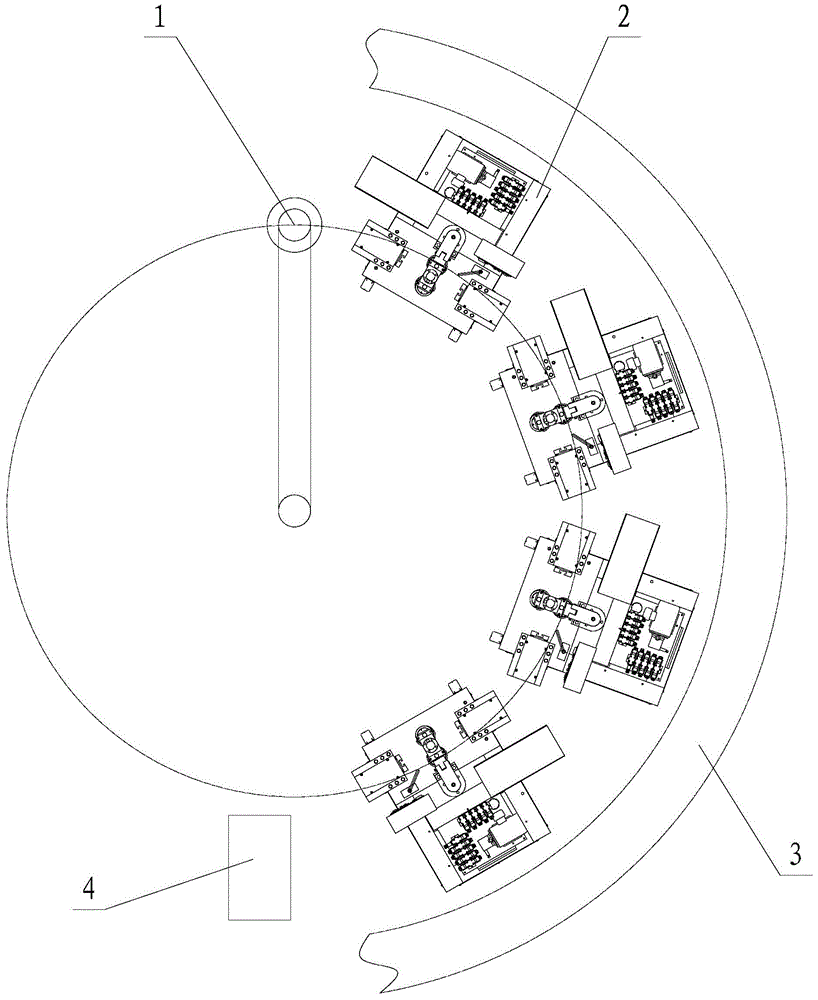

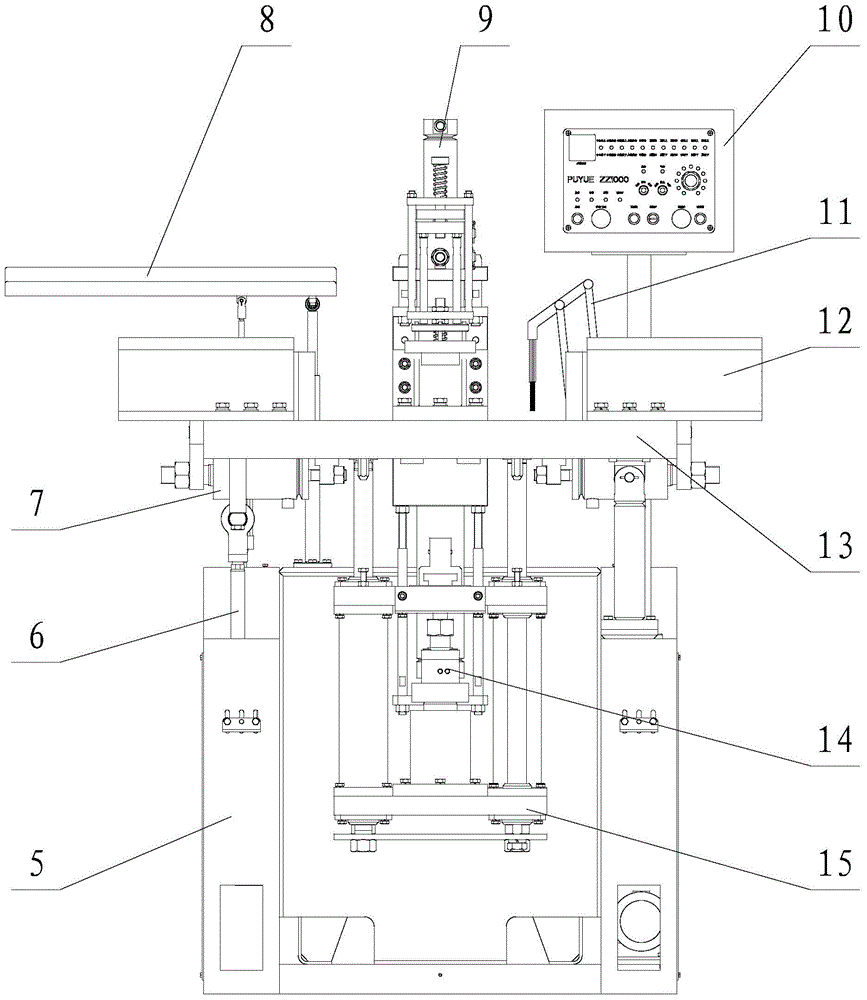

[0040] Such as figure 2 As shown, the present invention includes a bed 5, a tilting oil cylinder 6, a side block mechanism 7, a blanking plate mechanism 8, a top mold and a blanking mechanism 9, a control box 10, a spraying mechanism 11, an outer mold mechanism 12, and a workbench 13. For the core block lifting mechanism 14 and the lower core-pulling lifting mechanism 15, the equipment can design matching molds according to the specific process of the piston, and can adopt single-mode, double-mode or multi-mode structures. This embodiment takes dual-mode as an example.

[0041] One end of the tilting oil cylinder 6 is hinged on the bed 5 , and the other end is hinged to the workbench 13 above the bed 5 , and the tilting angle of the workbench 13 can be adjusted by the expansion and contraction of the tilting oil cylinder 6 . The blanking plate mechanism 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com