Marine lighting and sighting support

A cable-guide and marine-use technology, applied in theodolite and other directions, can solve problems such as time-consuming, system deviation accumulation increases, and high precision requirements for the placement of engine room support frames, so as to improve work efficiency, reduce safety hazards, and simplify the operation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

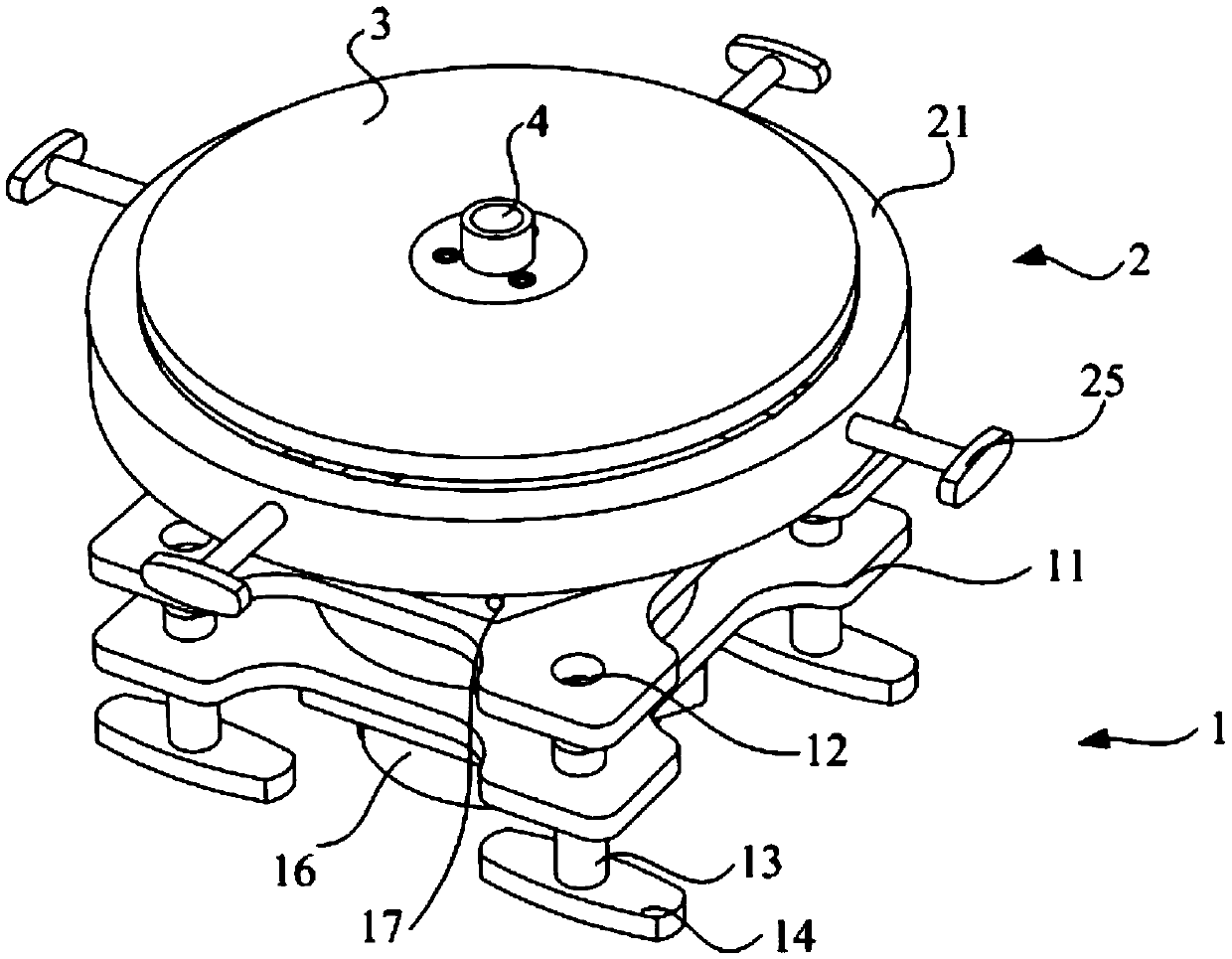

[0049] Such as Figures 1 to 14 As shown, in the embodiment of the present invention, the ship's stay wire viewing support includes a Z-axis lifting bracket 1, an XY-axis moving assembly 2 and a fixed plate 3, wherein the XY-axis moving assembly 2 is arranged on the top of the Z-axis lifting bracket 1, The reciprocating movement in the vertical direction can be realized through the Z-axis lifting bracket 1. The fixed disk 3 is arranged on the XY-axis moving assembly 2 to support the laser theodolite. The fixed disk 3 can realize the X-axis and X-axis in the horizontal direction through the XY-axis moving assembly 2. Y-axis movement.

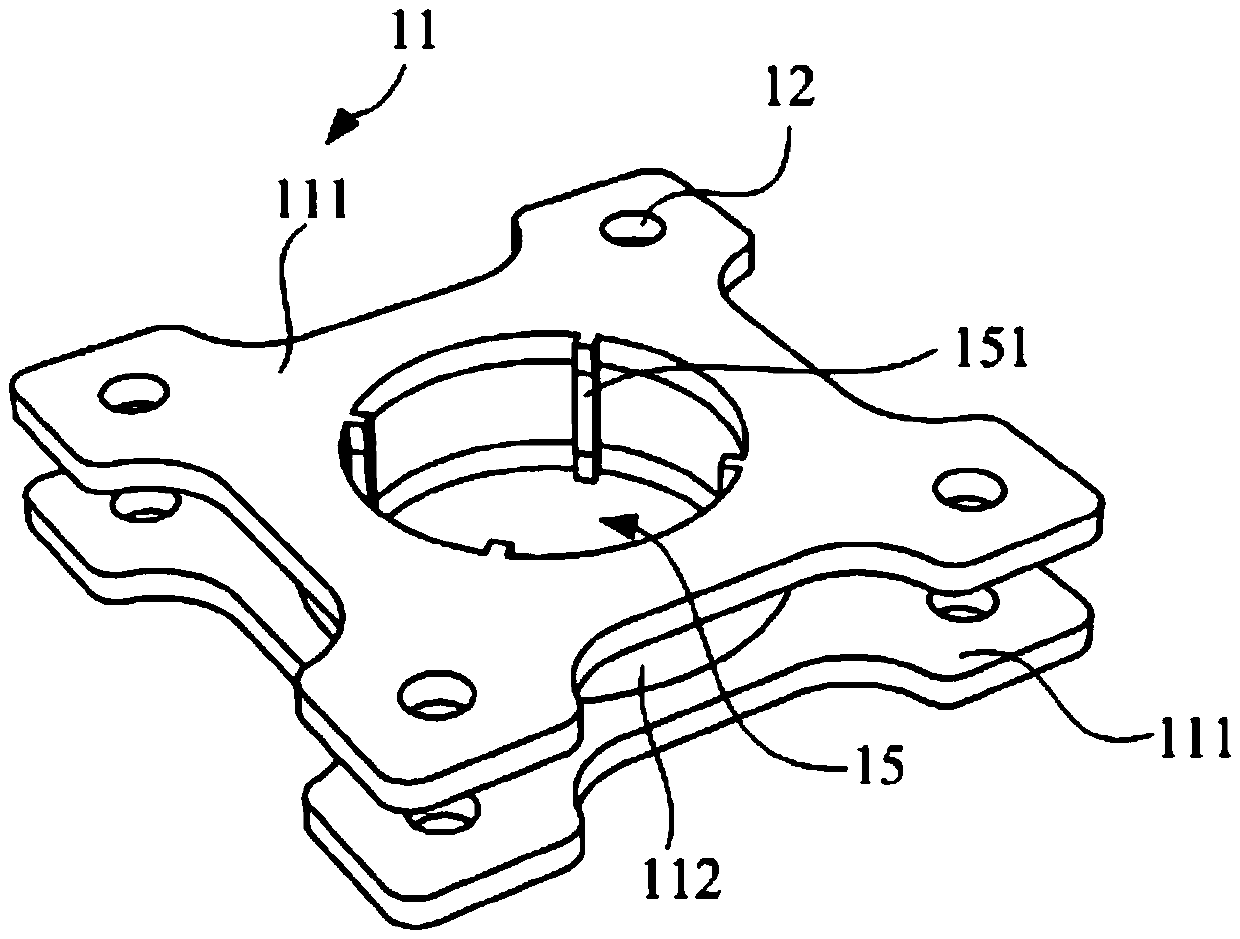

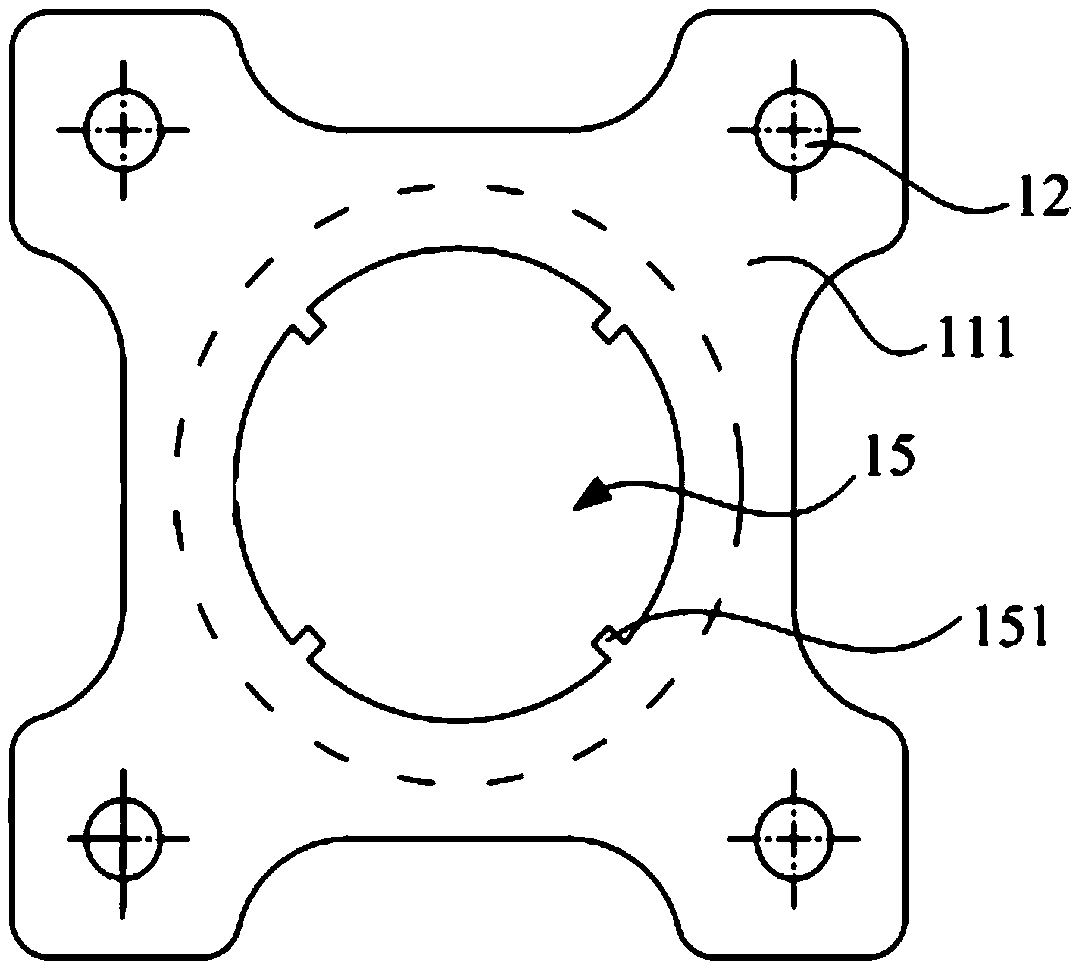

[0050] The Z-axis lifting bracket 1 includes a bracket body 11, and the four corners of the bracket body 11 are provided with a first threaded hole 12 along the Z-axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com