Preparation method of flame-retardant modified ramie fabric

A ramie and fabric technology is applied in the field of preparation of flame-retardant modified ramie fabrics, which can solve the problems of poor thermal stability and easy combustion of plant fibers, and achieves low cost, reduced total heat release, high heat resistance and carbon residue. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

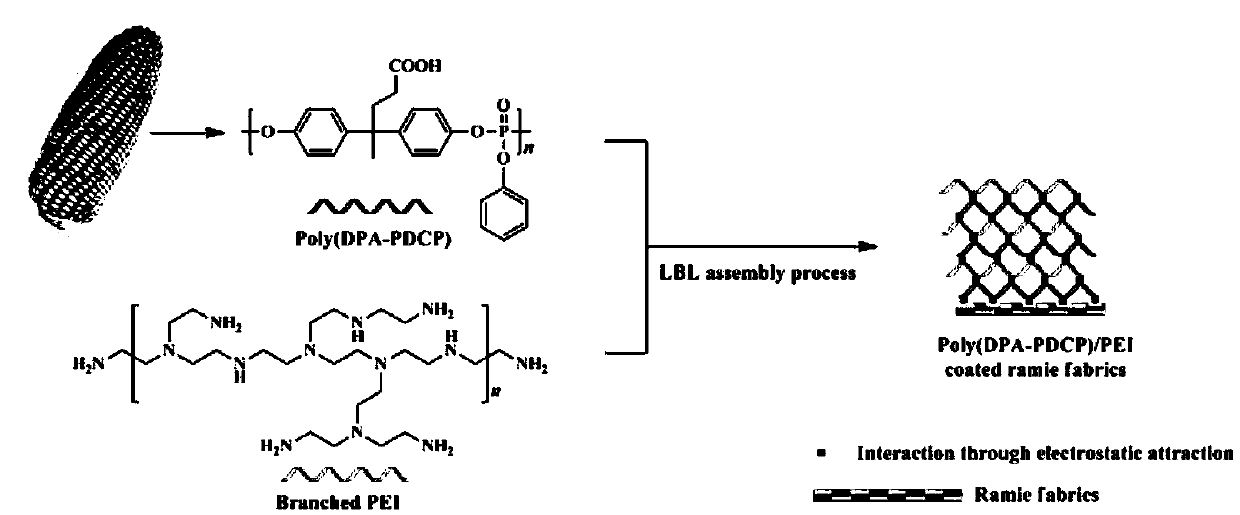

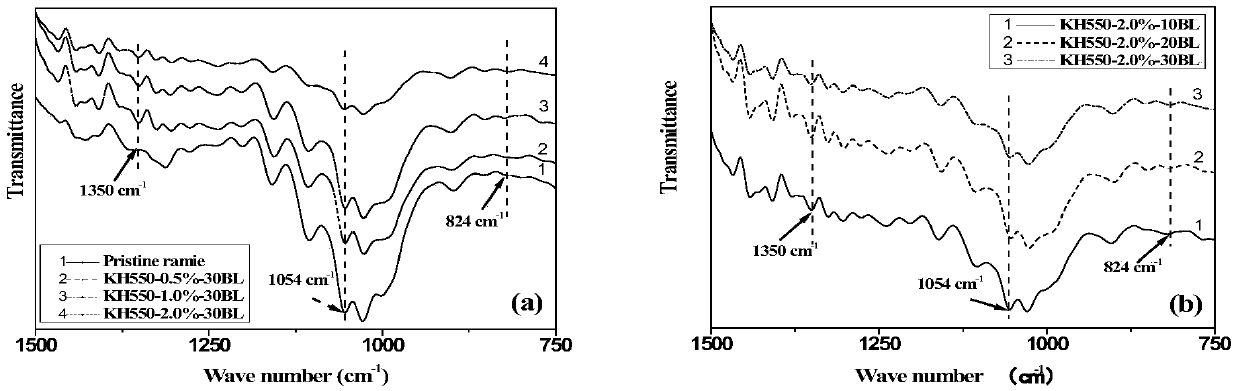

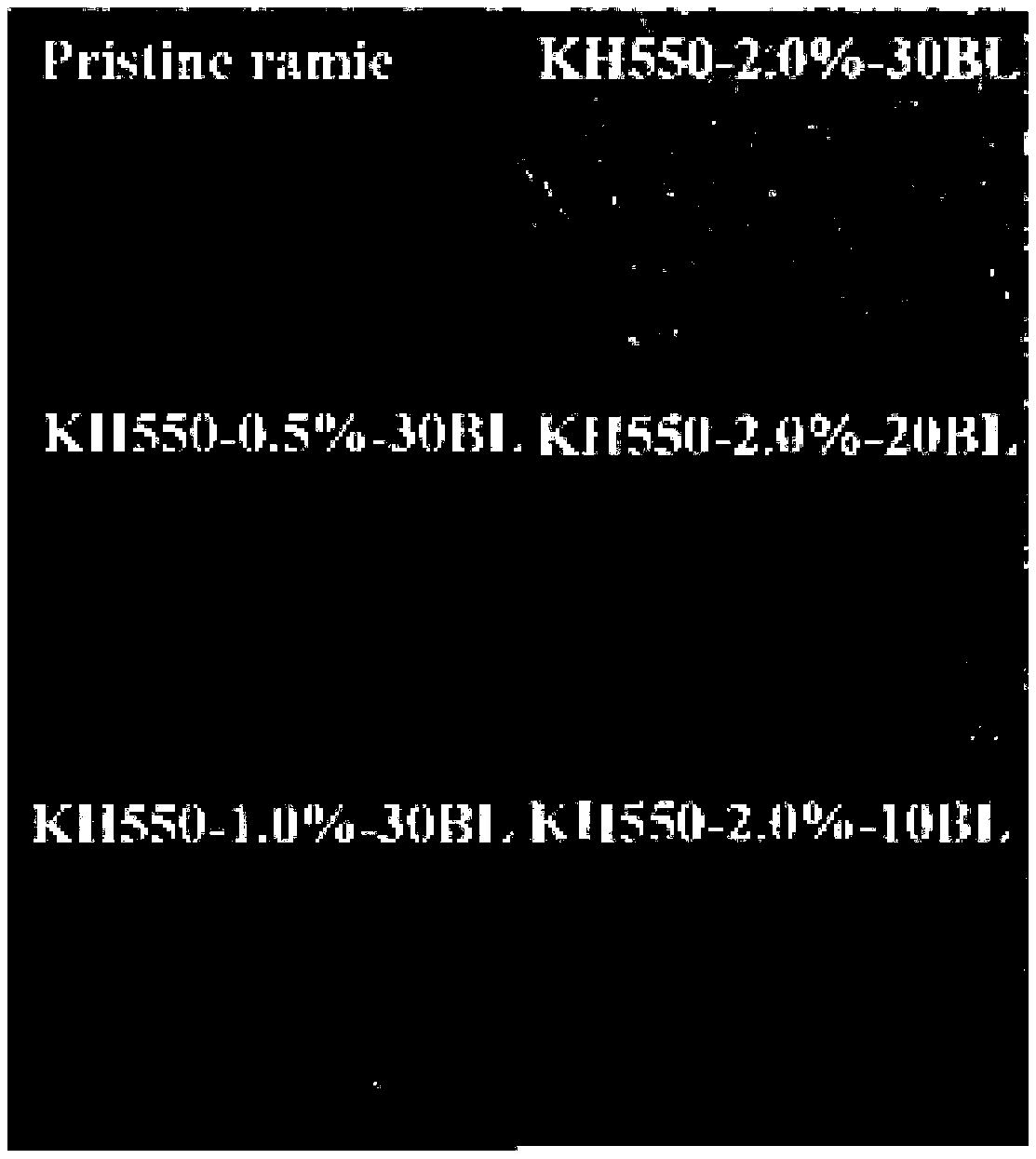

Embodiment 1

[0033] Soak the ramie fabric in 0.5wt% KH550 solution for 2h, take it out and dry it in a blast dryer at 60°C for 15min. The ramie fabric treated with KH550 is soaked in the polybisphenolic acid phenyl phosphate solution with a mass fraction of 0.5% and the PEI solution with a mass fraction of 1.0%. Ramie fabric. Repeat this process until 30 double-layer flame-retardant coatings are assembled on the ramie fabric surface, and its preparation process is as follows: figure 1 shown. Gained ramie fabric (KH550-0.5%-30BL) is placed in use N 2 Blow dry on the quartz plate, then place it in a blast drying oven at 60°C for 15 minutes, and then place it in a drying dish for 10 hours. Dry in a blast dryer at 70°C until constant weight. The content of flame retardant coating was calculated as 0.87% by weighing the mass of ramie fabric before and after treatment. The analysis result of the sample by thermogravimetric analyzer showed that the residual carbon content of KH550-0.5%-30BL ...

Embodiment 2

[0035] Soak the ramie fabric in 1.0wt% KH550 solution for 1 hour, take it out and dry it in a blast dryer at 70°C for 10 minutes. The ramie fabric treated with KH550 is soaked in the polybisphenolic acid phenyl phosphate solution with a mass fraction of 1.0% and the PEI solution with a mass fraction of 1.0% in sequence, soaking for 5 minutes each time, which is a double-layer fabric for flame-retardant finishing. Ramie fabric. Repeat this process until 30 double-layer flame-retardant coatings are assembled on the ramie fabric surface, and its preparation process is as follows: figure 1 shown. Gained ramie fabric (KH550-1.0%-30BL) is placed in use N 2 Blow-dry the quartz plate, then place it in a 70°C blast drying oven for 10 minutes, and then place it in a drying dish for 8 hours. The content of flame retardant coating was calculated as 1.73% by weighing the mass of ramie fabric before and after treatment. The analysis result of the sample by thermogravimetric analyzer sho...

Embodiment 3

[0037] Soak the ramie fabric in 1.0wt% KH550 solution for 1 hour, take it out and dry it in an air dryer at 80°C for 5 minutes. The ramie fabric treated with KH550 is immersed in the polybisphenolic acid phenyl phosphate solution with a mass fraction of 2.0% and the PEI solution with a mass fraction of 1.0% in turn, soaking for 10 minutes each time, this is a double-layer fabric for flame-retardant finishing. Ramie fabric. Repeat this process until 30 double-layer flame-retardant coatings are assembled on the ramie fabric surface, and its preparation process is as follows: figure 1 shown. Gained ramie fabric (KH550-2.0%-30BL) is placed in use N 2 Blow-dry the quartz plate, then place it in an 80°C blast oven for 5 minutes, and place it in a desiccator for 7 hours. The content of flame retardant coating was calculated as 3.14% by weighing the mass of ramie fabric before and after treatment. The analysis result of the sample by thermogravimetric analyzer showed that the resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com