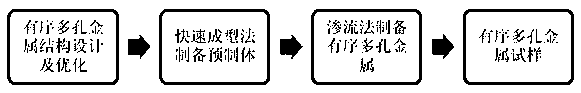

Design optimization and preparation method for ordered porous metal

A porous metal and metal technology, which is applied in the field of design optimization and preparation of ordered porous metals, can solve the problems of insufficient pore structure design and controllability, disordered pore structure, etc., to improve design and controllability. , The effect of reducing production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The ordered porous metal percolation of square holes includes the following steps:

[0026] The three-dimensional structure of the ordered porous metal with square holes is designed by using the three-dimensional drawing software ProENGINEER. The metal structure is a structure in which 3mm square holes are repeatedly arranged, and the complementary structure of the metal structure obtains the prefabricated structure accordingly. The structure of the ordered porous metal and the prefabricated body is a two-way interconnected structure. The matrix part and the pore part of this structure are completely interconnected and integrated, and the prefabricated body has several channels running through the entire prefabricated body in a certain direction, which can be used as seepage internal channels. . The structural design of the preform will be further optimized during the preparation of the preform and the next infiltration process. After the preliminary design is complete...

Embodiment 2

[0030] The orderly porous metal percolation of spherical pores includes the following steps:

[0031] Use the three-dimensional drawing software ProENGINEER to design the three-dimensional structure of the ordered porous metal with spherical holes. The metal structure is repeatedly arranged with 10mm spherical holes, and its complementary structure is correspondingly obtained. In this structure, the matrix part and the hole part are completely connected and integrated, and the prefabricated body has several channels running through the entire prefabricated body in a certain direction, which can be used as seepage internal channels. The structural design of the preform will be further optimized during the preparation of the preform and the next infiltration process. After the preliminary design is completed, the numerical simulation software ProCAST is used to simulate the seepage process. During the simulation, the pouring temperature is 850°C and the preheating temperature is...

Embodiment 3

[0035] The ordered porous metal percolation of spherical and cylindrical composite pores includes the following steps:

[0036] Use the 3D drawing software ProENGINEER to design the 3D structure of square holes and ordered porous metal. The metal structure is arranged with 10mm spherical holes and 5mm diameter and 10mm high cylindrical holes at intervals. The complementary structure of the metal structure is correspondingly obtained. The structure of the metal and the prefabricated body is a double-pass interconnection structure. The matrix part and the hole part of this structure are completely connected and integrated, and the prefabricated body has several channels running through the entire prefabricated body in a certain direction, which can be used as seepage internal channels. The structural design of the preform will be further optimized during the preparation of the preform and the next infiltration process. After the preliminary design is completed, the numerical sim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com