A kind of production equipment of carboxylic acid water reducing agent and production method thereof

A production method and technology of water reducing agent, which is applied in the field of production equipment of carboxylic acid water reducing agent, can solve problems such as fire, damage to reactor, personnel life safety and property loss, and achieve the effect of stable reaction and guaranteed product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

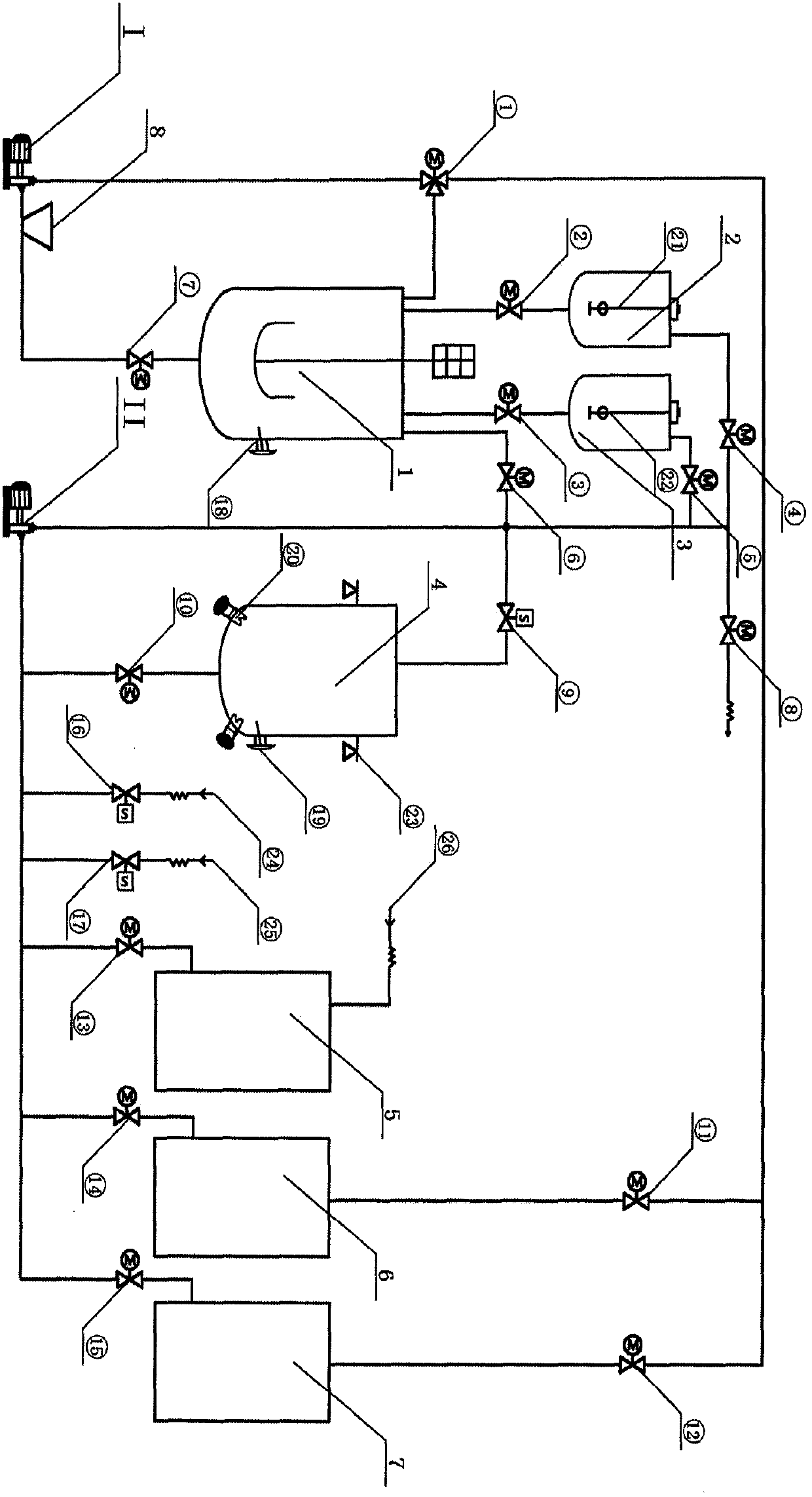

[0054] The technological steps of adopting the water reducing agent equipment of the new application for protection are as follows.

[0055] The electrical control system adopts PLC automatic control, and the man-machine interface is operated by touch screen. Start production, and the control system automatically works according to the program selected by the user.

[0056] Preparation before production: liquid raw materials of acrylic acid, catalyst, neutralizer, and oxidant are transported to the production site, and the corresponding straws are inserted into the packaging barrel for use. The solid raw materials are manually transported to the side of the powder material delivery port according to the specified quantity for standby.

[0057] Automatic catalyst preparation according to the control program: softened water storage tank output automatic valve Open, the batching tank input automatic valve ⑨ is opened, the batching pump II starts, and the free water enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com