Support-provided film for vacuum glass and manufacturing method

A technology of vacuum glass and support, applied in glass manufacturing equipment, glass production, glass forming and other directions, can solve the problems of destroying the overall flatness of vacuum glass, glass influence, etc., to maintain vacuum degree, improve production efficiency, and easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

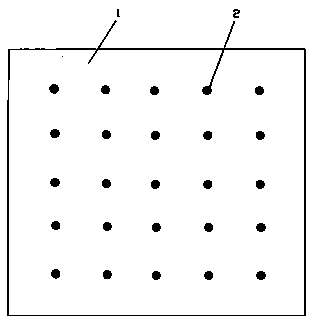

[0026] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of an embodiment of a self-supporting film for vacuum glass in the present invention. A self-supporting film for vacuum glass, comprising:

[0027] A film substrate 1;

[0028] A set of supports 2, the supports 2 are protruding structures arranged in an array, the supports 2 are fixed on the film substrate 1 through an adhesive material, and the material of the film substrate 1 is a transparent plastic film, The bonding material is glass solder.

[0029] The film with its own support is placed between two or more glass plates, and the adjacent glass plates are supported by the support to form a vacuum space. The support is columnar and made of glass.

[0030] A method for making a film with a self-contained support for vacuum glass, comprising the following steps:

[0031] (1) The film substrate 1 is obtained by injection molding with a mold through an injection molding machine;

[0032] (2) ...

Embodiment 2

[0034] A self-supporting film for vacuum glass, comprising:

[0035] A film substrate 1;

[0036] A set of supports 2, the supports 2 are protruding structures arranged in an array, the supports 2 are fixed on the film substrate 1 through an adhesive material, and the material of the film substrate 1 is a transparent plastic film, The bonding material is vacuum sealant.

[0037] The self-supporting film is placed between two or more glass plates, and adjacent glass plates are supported by supports 2 to form a vacuum space. The supports 2 are columnar and made of glass.

[0038] A method for making a film with a self-contained support for vacuum glass, comprising the following steps:

[0039] (1) The film substrate 1 is obtained by injection molding with a mold through an injection molding machine;

[0040] (2) Coating the bonding material on the bottom of the support 2 with a spreader, and orderly distributing the support on the surface of the film substrate 1 by printing r...

Embodiment 3

[0042] A self-supporting film for vacuum glass, comprising:

[0043] A film substrate 1;

[0044] A set of supports 2, the supports are protruding structures arranged in an array, the supports 2 are fixed on the film substrate 1 through an adhesive material, and the material of the film substrate 1 is a translucent plastic film, The bonding material is vacuum sealant.

[0045] The self-supporting film is placed between two or more glass plates, and adjacent glass plates are supported by supports 2 to form a vacuum space. The supports 2 are C-shaped and made of high-temperature-resistant organic materials .

[0046] A method for making a vacuum glass with a self-contained support film, comprising the following steps:

[0047] (1) The film substrate 1 is obtained by injection molding with a mold through an injection molding machine;

[0048] (2) Coating the bonding material on the bottom of the support 2 with a spreader, and orderly distributing the support on the surface of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com