Ocean platform submersible pump winding and unwinding method

A technology for offshore platforms and submersible pumps, applied in hoisting devices and clockwork mechanisms, etc., can solve the problems of multiple supporting equipment and complex operations, and achieve the effects of reducing work intensity, high economy, and strong adaptability to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

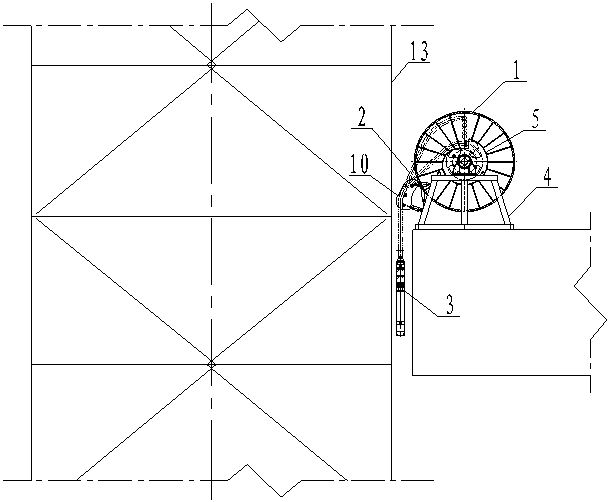

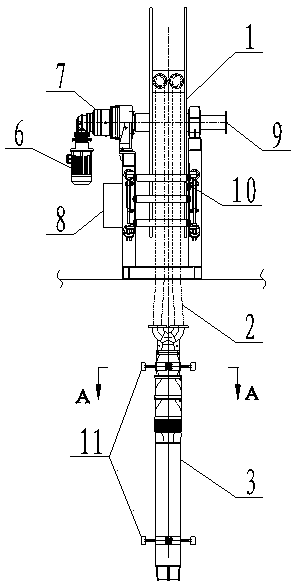

[0013] Such as figure 1 , figure 2 with image 3 As shown, the present invention consists of a hose winch (1), combined hose (2), submersible pump (3), winch support (4), winch drum (5), motor (6), reduction box (7), control Box (8), seawater output port (9), hose guide device (10), pump body guide frame (11), pile flushing pipeline (12). Connect the submersible pump (3) to one end of the combination hose (2), which is wound on the winch drum (5) on the hose winch (4), start the motor (6) through the control box (8) ), the reduction box (7) realizes the synchronous retraction and retraction of the submersible pump (3) and the combined hose (2). The seawater output terminal (9) is directly connected with the platform.

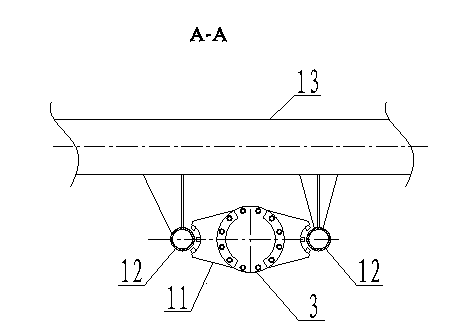

[0014] The pile flushing pipeline (12) on the pile leg (13) is used as the guide track of the submersible pump, and the submersible pump is equipped with a pump body guide frame (11) matched with the pile flushing pipeline, and a hose winch (1) is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com